Commercial printing is the printing of publications, catalogs, direct mail, and other promotional materials necessary for projects and business. Unlike offset printing, for which it is necessary to create a plate, digital printing enables short turnaround time, short run production for a broad range of applications, and variable printing for which the details can be changed for each copy, so the demand for this style of commercial printing in particular is increasing every year. Canon has been working with Canon Production Printing, one of its group companies, to promote various types of technological development in an effort to pursue enhanced digital-printing productivity and image quality. In particular, the company is focusing on the graphic arts field, including premium direct mail and catalogs, coffee table books, posters and signage. In addition, the company is exploring new possibilities for printing, such as by developing elevated printing technology, which makes it possible to produce textured prints.

2018/12/27Featured Technology

#Technology in Products#Printer

#Commercial printing#Imaging technologies

Continuous printers can continuously print on paper rolls at high speed. They are suitable for transaction printing such as statements and invoices, direct mail, books, manuals, and other materials.

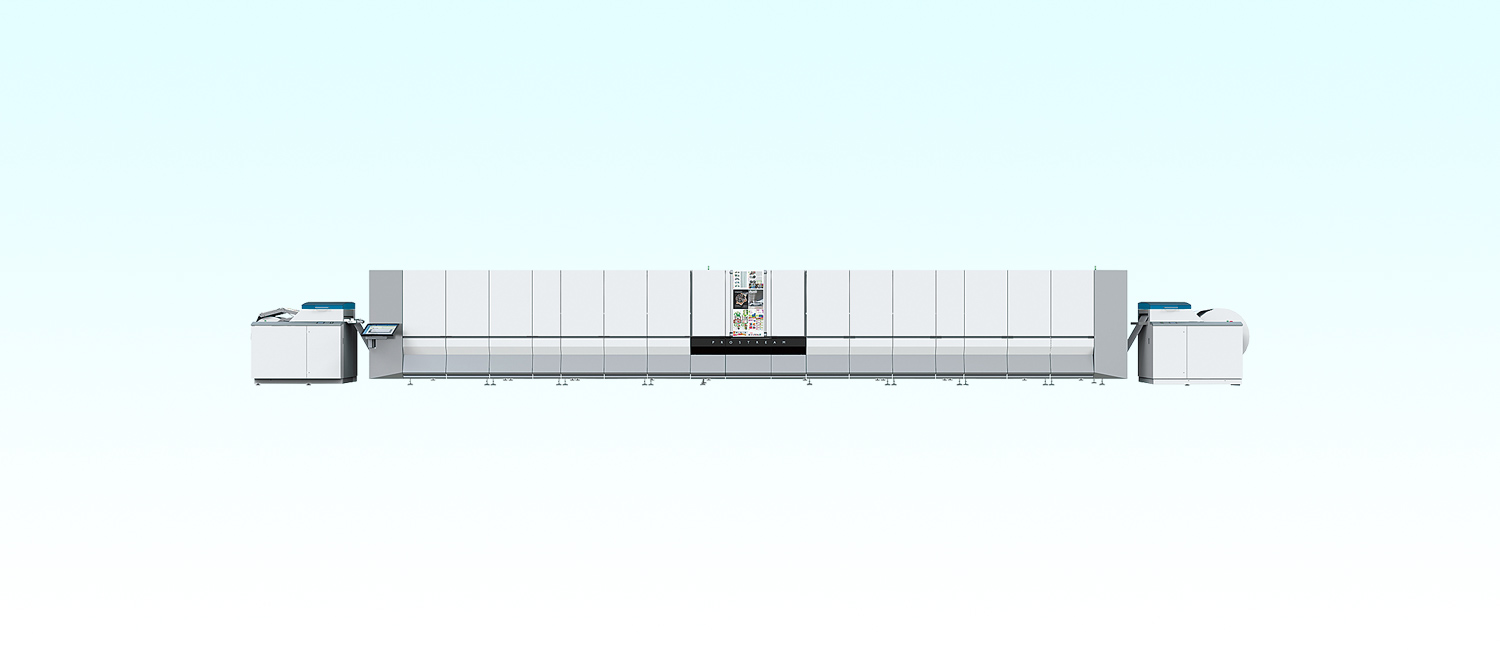

The ProStream 1000, a continuous feed printer for graphic arts printer

The high-speed feed commercial printer ProStream 1000 is packed with Canon Production Printing(CPP)* technologies, including a ColorGrip that achieves high image quality, independently developed ink, and a drying method that helps to reduce paper degradation, all of which make it possible to print at high quality even on coated paper used for offset printing.

*

Changed its name from Océ in 2020. This Netherlands-based company joined the Canon group in 2010 and accounts for a large share of the commercial production printer market.

#Commercial printing#Imaging technologies#Chemistry

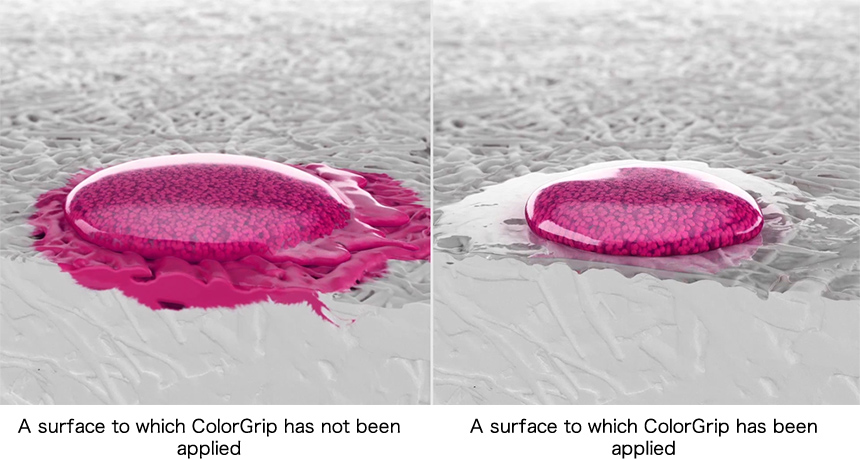

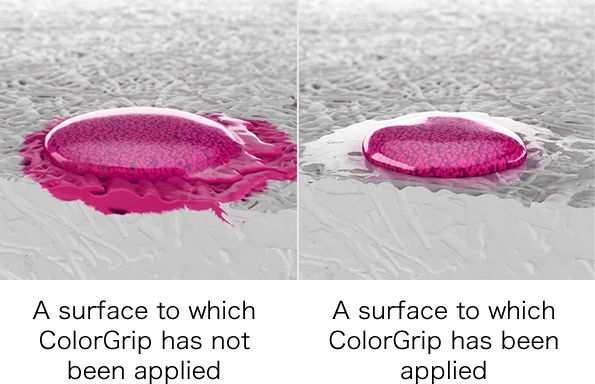

Ink set technology makes it possible to achieve high image quality on various types of paper. One technology that supports this is ColorGrip, a media-pretreatment. The ColorGrip is applied to the surface of the paper before the ink used for printing. This makes it possible to prepare the surface of the paper without altering its texture so that pigment particles can be quickly fixed to it. The ColorGrip is also effective for ensuring that a uniform amount of ink is applied when printing an image.

In addition, the company’s own unique polymer pigment ink contains a polymer component, which makes print images much more robust and makes it possible to achieve vivid colors for a wide range of media.

Depending on the images to be printed, the ProStream 1000 can eject 2 or 4.6-picoliter* ink droplets (multilevel drops) from the ink head to achieve smooth gradations. The printer can also handle a high resolution of 1,200 dpi.

Multilevel drops

#Commercial printing#Imaging technologies#Physics

The ProStream 1000 uses air flotation non-contact drying technology, which involves melting ink at a high temperature, applying it, and then quickly drying it in order to achieve printing with high image quality for a wide range of media including offset coated media. This was once thought difficult to achieve. First, air that has been heated to 160°C is blown against both sides of the paper to make the paper roll float. Next, the temperature of the paper is gradually increased to 100°C or more depending on the paper and image requirements, the ink polymer particles are melted, and an glue layer is formed around the pigment. After that, cooling is used to reduce the temperature of the paper roll to 60°C or less, which causes the ink to cool and fixes a hot, wet polymer layer in place. Because both heating and cooling are accomplished using a drying method that does not require contact with the paper, the process ensures minimum stress on paper. The printer can therefore support the printing on various types of media and achieve double-sided printing at a high speed of 80 m/minute while keeping haptics and gloss levels of the original paper unchanged.

#Commercial printing#Imaging technologies

In fields that require high-quality large-format printing, Canon has achieved the practical implementation of various technologies that improve image quality, productivity, durability, and other characteristics. In particular, the Colorado 1640 uses own unique developed UVgel inks and other technologies for maintaining high quality.

#Commercial printing#Imaging technologies#Chemistry

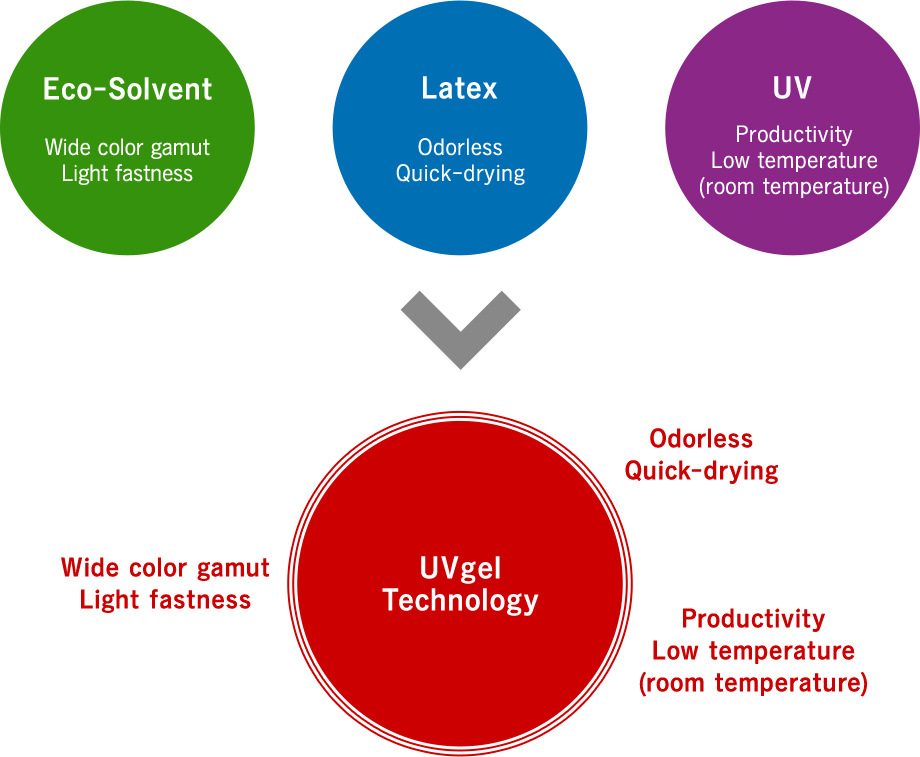

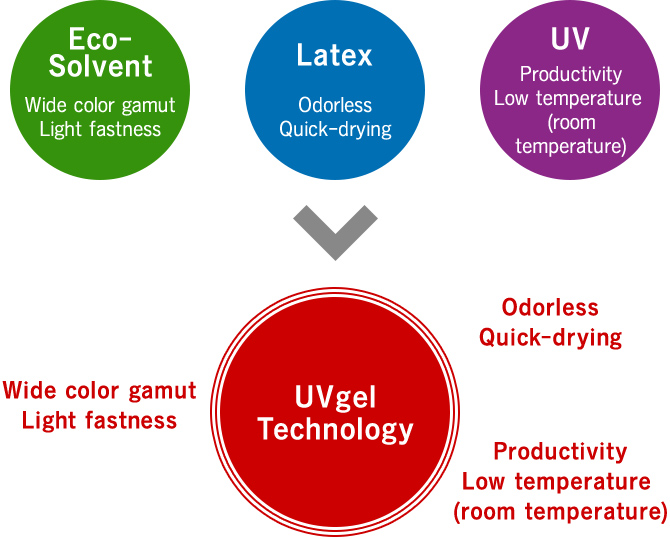

CPP’s proprietary UVgel inks combine the strengths of existing ink technologies. They exploit the strengths of eco-solvent, which offers a wide color gamut and light fastness, latex, which offers environmental advantages such as less or even no odor, and UV inks, which can be cured immediately.

Because UVgel inks are a gel, there’s no unnecessary ink mixing, the inks offer high printing-position accuracy, and a wide color gamut can be achieved with only the four CMYK colors.

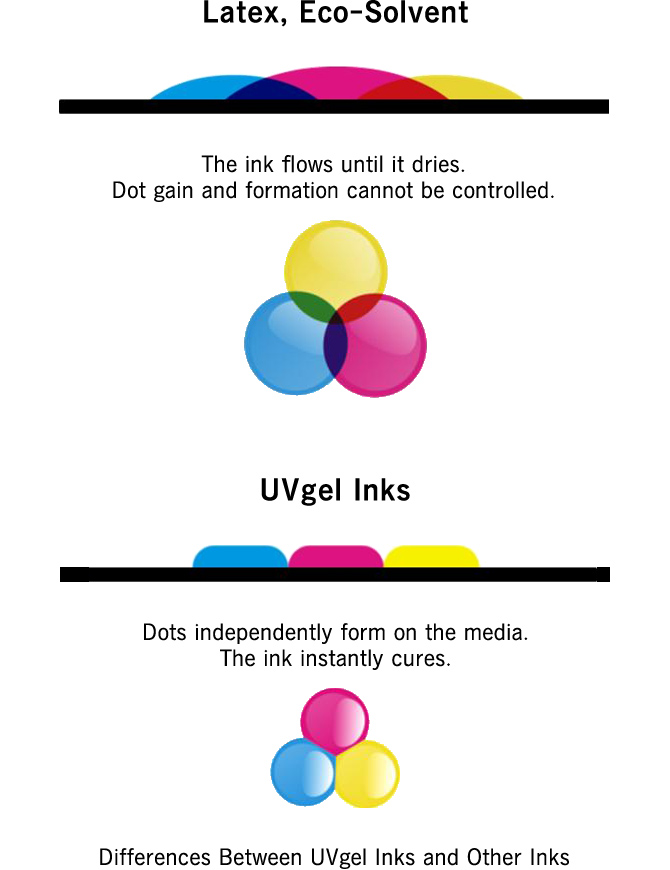

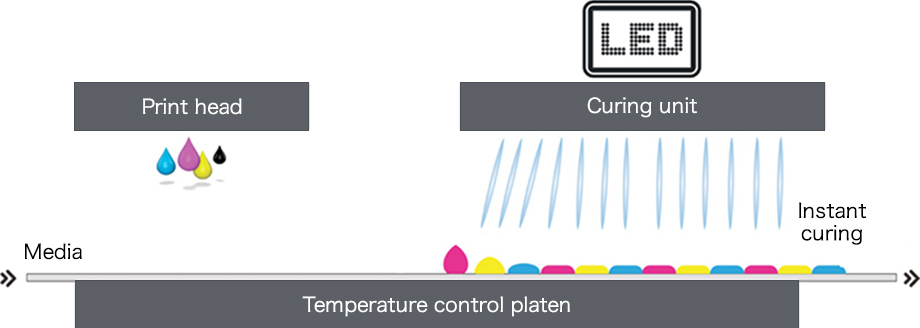

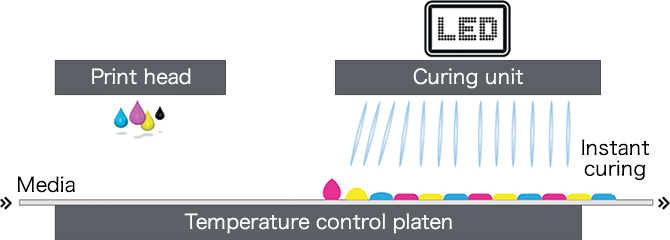

In addition, with conventional liquid inks, in order to prevent the inks from spreading and bleeding after they are applied to the paper, it is necessary to cure the inks immediately after ejecting them. Therefore, the print head used to eject the ink and curing unit are unified. However, because the Colorado 1640 uses gel inks, the shape of the inks can be maintained even if they are not cured immediately after ejection, so it is no longer necessary to unify the print head and curing unit. As a result, it was possible to increase the amount of ejected ink and improve the printing speed without worrying about curing.

In addition, with conventional UV inks, because ink ejection and curing were repeated as necessary, the surface of the paper sometimes ended up rough after printing, which could result in air bubbles when laminating the paper for waterproofing purposes, etc. or diffuse light reflection. With CPP’s UVgel inks, because curing is performed after ink ejection is completely finished, the flatness of the printed surface can be maintained, which made it possible to resolve problems that conventionally occurred during lamination.

Separate Print Head and Curing Unit

#Commercial printing#Imaging technologies#Physics

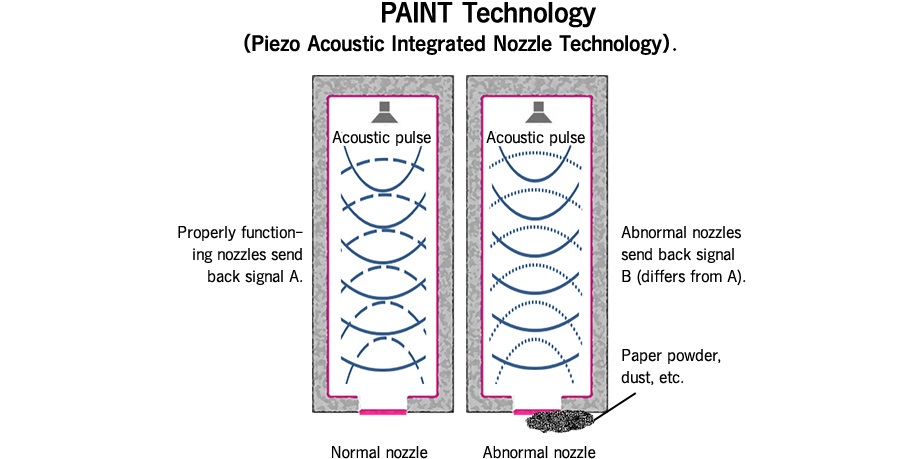

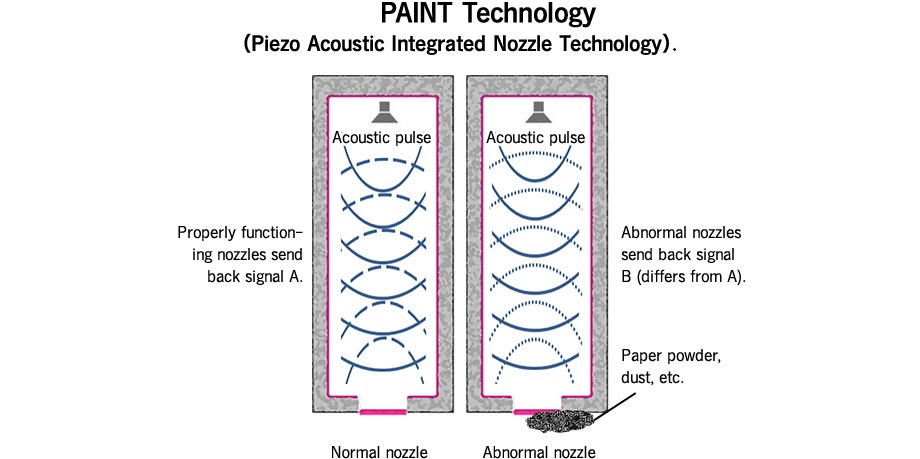

Long-hour printing can lead to paper powder and dust causing nozzle failures (nozzle clogging), which makes it impossible to achieve expected printing results. Trying to do nozzle maintenance or replace a problematic nozzle results in downtime during which printing is not possible and gets in the way of improving productivity. To solve this problem, PAINT technology was developed to detect nozzle failures.

For this technology, acoustic pulse are directed at all the nozzles on the print head, and the resulting echoes are measured. If the echo does not lie within a certain bandwidth, because the system detects nozzle clogging before ink is ejected, the clogged nozzle can be complemented by other nozzles before it causes a problem. This is an extremely important technology for ensuring that it is always possible to achieve high-quality printing.

#Commercial printing#Imaging technologies#Chemistry

UV inks have a distinct odor, but UVgel technology has made it possible to reduce this odor while still using UV inks. Therefore, materials printed using UVgel inks can be used for not only outdoor but also indoor purposes. In addition, because there is low thermal load applied to the media, it is possible to handle both thin vinyl and other media that is weak to heat as well as offset coated paper and other low-cost media. On top of that, because it is not necessary to use separate printers as it was due to differences between eco-solvent and latex inks, one Colorado unit can be used to handle many applications.

Printed Materials that Use UV Inks

#Commercial printing#Imaging technologies#Chemistry

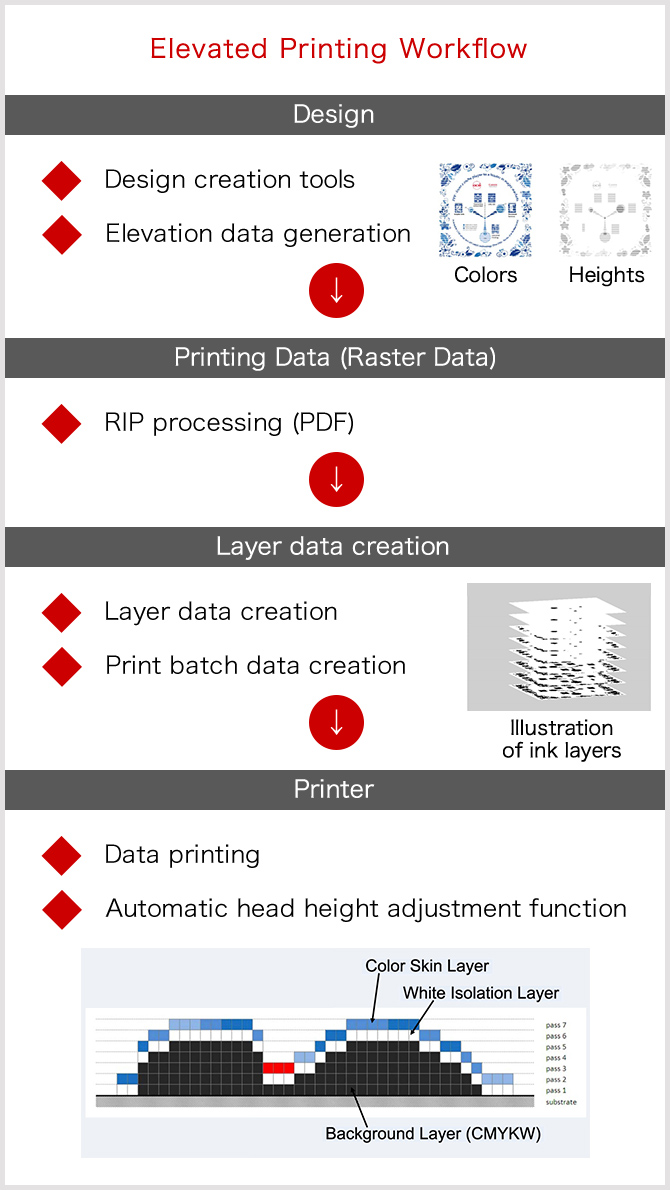

Elevated printing technology involves using UV curable ink and overprinting multiple layers of ink to produce textured output. This has made it possible to achieve appearances and tactile feeling that were once impossible.

#Commercial printing#Imaging technologies#Social contribution#Chemistry

Egypt is home to the Valley of the Kings, a World Heritage Site and the location of the cave tombs of many ancient Egyptian pharaohs. These tombs have deteriorated since they were discovered in 1817. To reconstruct this aspect of ancient Egyptian culture, in 2016, the Factum Foundation for Digital Technology in Conservation, an NPO, collaborated with CPP as part of their social contribution activities to reproduce the walls, pillars, and sarcophagus of the tomb of Seti I, the pharaoh of the 19th dynasty, based on 3D data of the tomb filmed by the foundation. CPP used its proprietary elevated printing technology to print relief sculptures that are up to 15 mm thick. Factum Arte handled the final processing, and some parts of the reproduced tomb are being shown at a special exhibition at Antiken Museum, a museum of ancient history in Switzerland.

Décor Reproduced Using Elevated Printing

#Commercial printing#Imaging technologies#Social contribution#Chemistry

In the Dutch province of North Brabant, CPP has created tactile street signage that provides information to the visually impaired and tourists. The plan was originally devised by a student from North Brabant, and CPP worked with Dedicon (a government-funded organization that provides contents for the blind) to pursue the project. The tactile street signage includes both street names written in Braille and elevated QR codes. The signs are positioned at major areas around town, and they offer Braille-based assistance to visually impaired residents and visitors. In addition, the elevated QR codes provide information on the current location, nearby buildings, and information on how to get to famous places, etc.

Décor Reproduced Using Elevated Printing

#Commercial printing#Imaging technologies#Social contribution#Chemistry

CPP used its elevated printing technology to help provide paintings for the visually impaired, which have been displayed at the Musée du quai Branly - Jacques Chirac in Paris, France. CPP used elevated printing to create reproductions of three paintings: Fighting antelopes (Jean Dunand), Portrait of Savorgnan de Brazza (Alphonse Monchablon), and Mourners in Cairo (Émile Bernard). The surfaces of the reproductions are greatly elevated, and visually impaired visitors can listen to the voice guidance system while touching the works to gain an understanding of their composition and enjoy them. Another major feature of the works is that, because they are printed based on high-definition photographic data, they faithfully reproduce the original artists’ brush strokes and use of color.

This project was planned by Mikli Diffusion France, a Paris-based company that is involved in the high-fashion eyewear brand Alain Mikli, as part of the company’s efforts to support the visually impaired. CPP agreed with the aims of the plan and therefore provided technical cooperation.

A Visitor Touching an CPP Work to Enjoy Art Appreciation

A Print with a Greatly Elevated Surface for Visually Impaired Persons