Inkjet printers, which allow almost anyone to easily create high-quality photo prints, are a combination of high-precision technologies, including ink and print head technology. Canon's capacity to combine component technologies is elevating the quality of inkjet printers to new heights.

2018/12/27Featured Technology

#Technology in Products#Printer

Ever since Canon developed the basic bubble jet mechanisms used in inkjet printers in the mid-1970s, the company has continued to foster new ideas and original technologies in the field. The key technology behind these innovations is Full-Photolithography Inkjet Nozzle Engineering, or FINE. FINE's ink ejection mechanism and print head manufacturing technology have enabled Canon to achieve dramatic improvements in image quality, gradation expression and image stability.

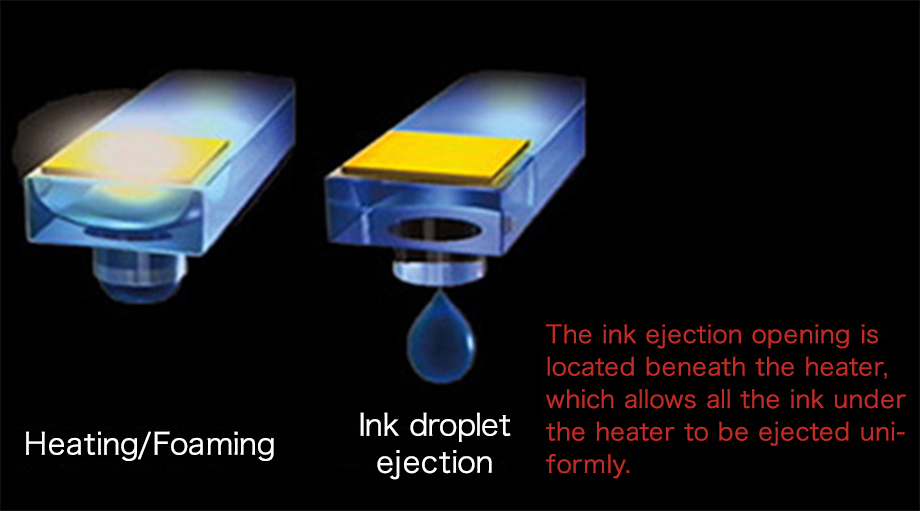

Microscopic ink droplets and precise ejection are essential to achieving high-quality photo printing. With conventional ejection systems, however, the finer the ink droplets, the more vulnerable they are to airflow disturbances from print head movement and to changes in ink viscosity that occur due to temperature fluctuations, resulting in inconsistent ejection volumes and ink dot placement. Canon's FINE print heads ensure that all of the ink under the heater is pushed out in a single ejection to ensure efficient performance. Ink droplet placement speed has been increased to more than 1.5 times that of conventional systems, reducing its susceptibility to airflow disturbances caused by print head movement to enable increased placement accuracy.

FINE’s Ink-Ejection Process

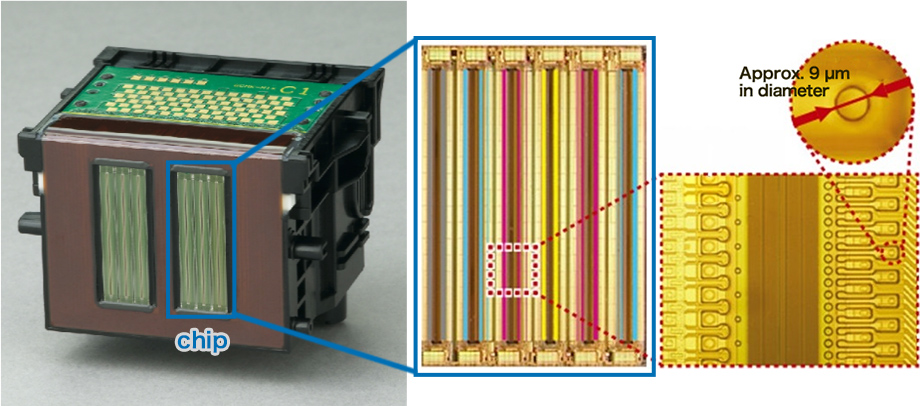

Achieving smaller droplet sizes and faster print speeds requires high-precision fabrication technologies that enable the placement of a greater number of nozzles over a wider area. Canon makes the most of its expertise in semiconductor production, as well as its original material technologies and innovative processing technologies, to integrate the heaters and nozzles into a single unit on a wafer. The resulting FINE print heads fit approximately 6,000 nozzles on a chip with an area measuring a mere 20 mm x 16 mm, roughly the size of a thumbprint.

Print Head with Enlarged View of Nozzle Configuration

#Imaging technologies#Chemistry

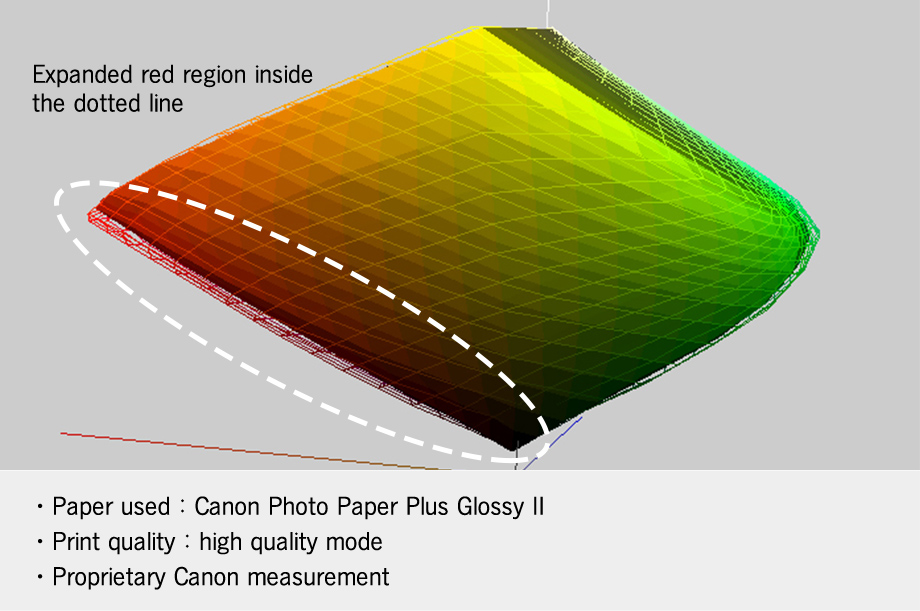

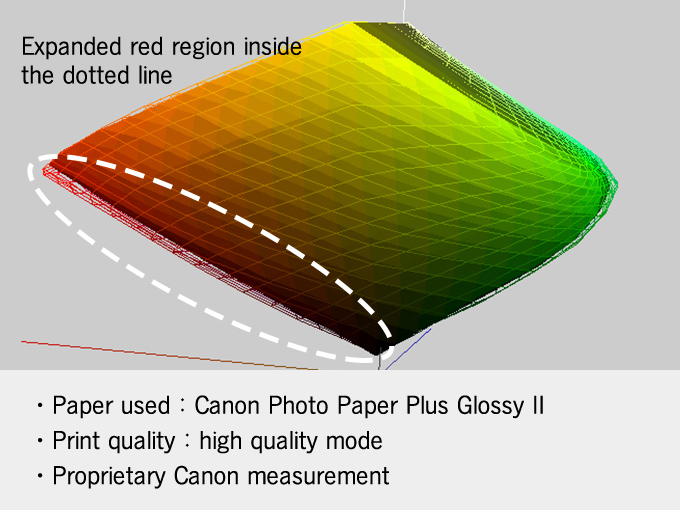

ChromaLife100+ is an advanced system for preserving the beauty of photos that combines Canon's genuine dye inks1 and genuine photo paper to produce photos with an approximately 300-year album storage period, approximately 40-year light fastness, and approximately 10-year gas fastness against ozone.2 Ink for inkjet printers must perform across a variety of parameters simultaneously, including heat stability, maintaining fine droplet configuration (proper spheres) and safety. Bright coloration, high ink density and fade resistance are also vital. Due to the modification of the dye architecture of the ink and the addition of an agent that improves longevity to the ink-receiving layer of the photo paper, gas fastness and light fastness have been improved significantly. What’s more, expanding the reproduction of colors in the red region has made it possible to maintain rich, vivid colors over an extended period of time.

#Imaging technologies#Chemistry

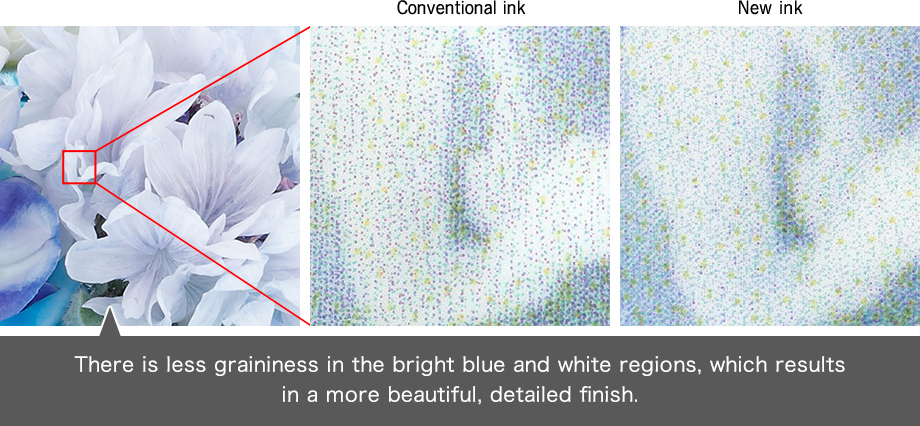

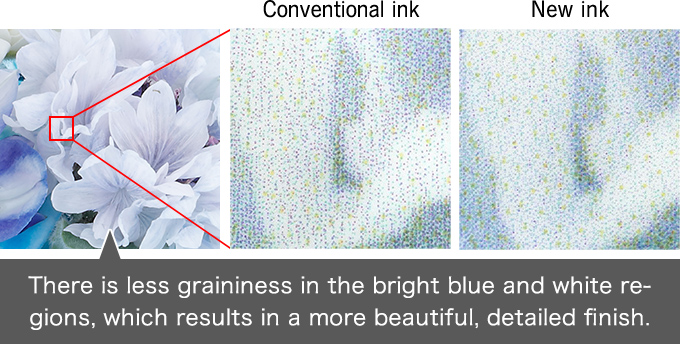

The premium six-color hybrid-ink system used by the PIXMA TS series, released in 2018, features an improved magenta ink that makes possible more vivid reproduction of colors in the red region. Additionally, Canon’s new Photo Blue ink improves the expression of colors achieved through the combination of cyan and magenta inks while simultaneously reducing graininess in the blue and white regions. This makes it possible to smoothly beautifully reproduce scenery, skin, and even faint colors with greater consistency.

Improved color reproduction through the use of new inks

Reduced graininess through the use of Photo Blue ink