Canon has combined many of its advanced optical, electronic device, and software technologies to create scanners that enable the conversion of camera film, photo prints, and text documents into high-grade digital data.

2018/12/27Featured Technology

Enhancing Work Efficiency and Conserving Energy

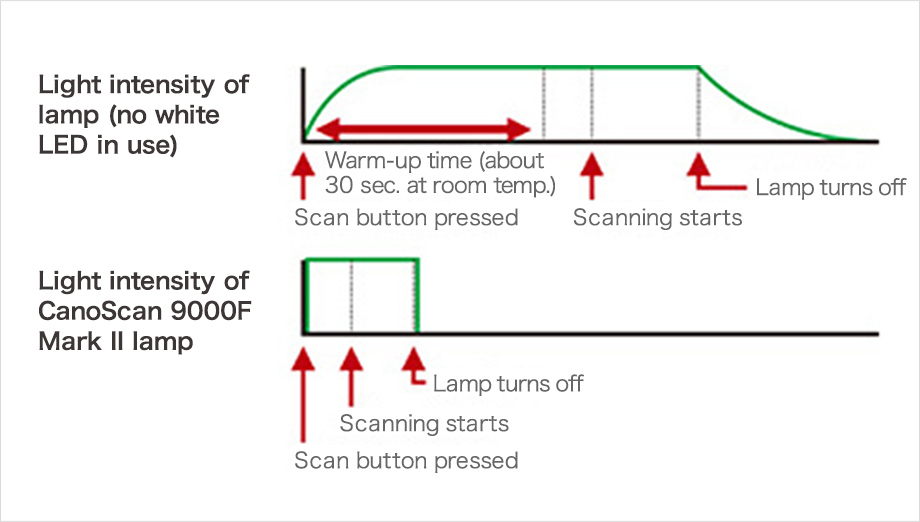

With conventional CCD scanners that employ fluorescent lamps, about 30 seconds of warm-up time is required after startup or re-activation from sleep mode. While using an LED as the light source eliminates the warm-up time, because it is a point light source, technology is needed to convert it into a linear light source with uniform light intensity.

By applying the LED light guide technology Canon developed for its CIS scanners and improving LED installation and light guide formats, the company was able to develop a high-brightness white LED light source for scanners. This technology ensures stable light intensity immediately upon starting up the scanner, reducing warm-up time to zero. In addition, it is no longer necessary to keep the light on after scanning, which helps save energy.

Reduction of Warm-up Time Through Use of White LED Lamp

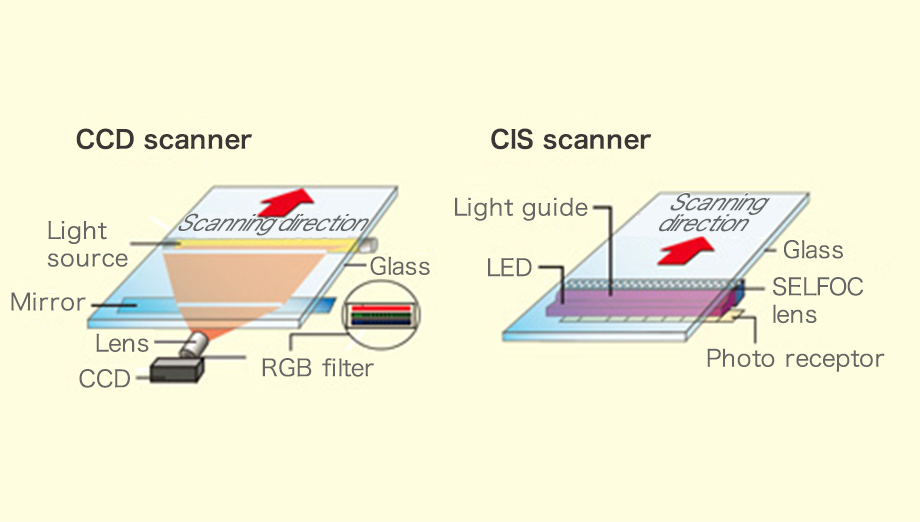

Canon offers two types of flatbed scanners: CCD and CIS. CCD models incorporate high-precision optics and high-density CCD line sensors that illuminate the document with a light source such as a white LED to deliver sharp, high-resolution images. CIS scanners are slim-bodied, energy-efficient models that utilize a three-color RGB LED as the light source and read documents with a CIS (Contact Image Sensor) of the same width as the original document.

CCD and CIS Systems

#Imaging technologies#Electrical engineering#Computer science

The scanning mechanism is not the only factor that determines scanner performance. The driver that processes data from the scanner and reproduces images is equally important. Canon's ScanGear scanner driver is designed not only to enable exceptional ease of use but also to deliver a wide range of image-processing features. This image-processing technology is based on platform technology used in other Canon digital imaging devices but has been specially customized for use in scanners.

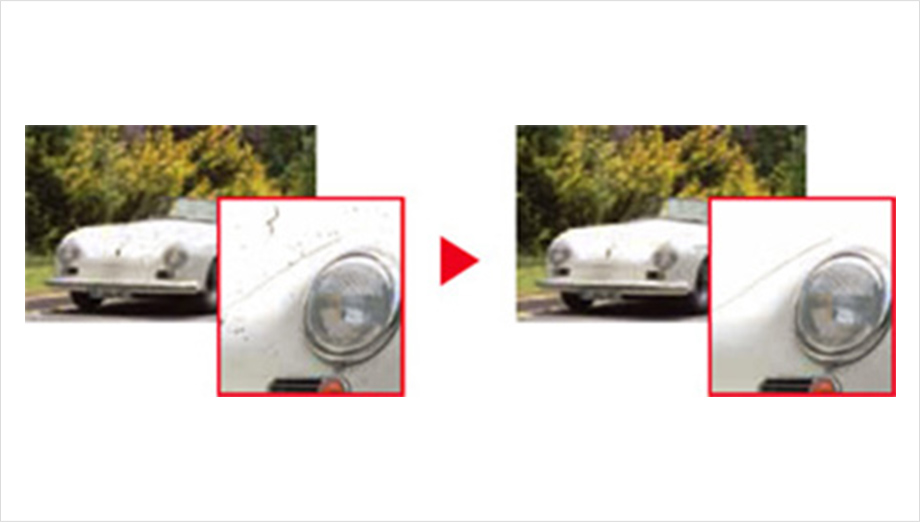

When scanning photographic film using a high-resolution scanner, minute dust particles and scratches that are invisible to the naked eye are picked up. The dust and scratch removal function first detects dust and scratches with infrared light from an infrared LED and then determines the size and shape of the dust and scratches along with the characteristics of the surrounding image. Next, the dust and scratches are automatically removed through a high-level integration of hardware and software processing to create a beautiful reproduction.

The discoloration correction function restores vivid colors to film or photo prints that have faded or display color bleeding. The histogram of the scanned image is analyzed and the hue, color balance, contrast, and saturation are automatically adjusted to appropriate levels.

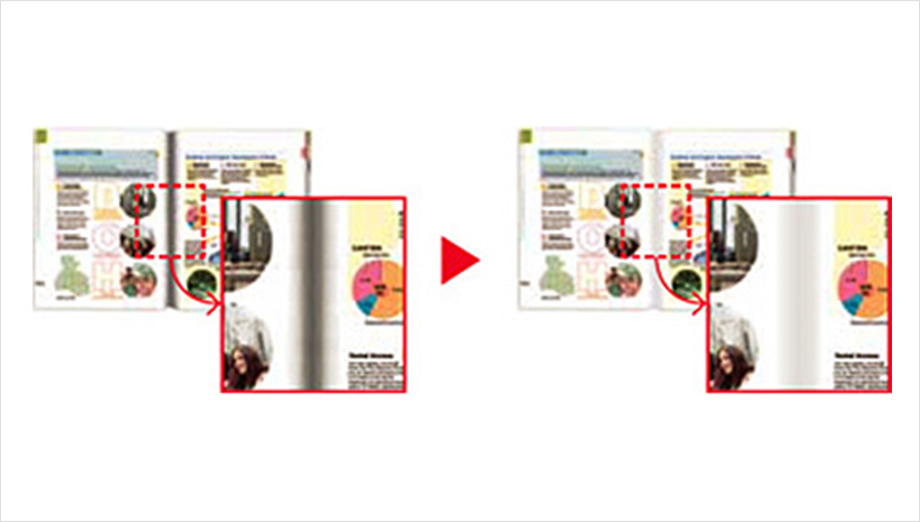

This corrective function reduces the shadow that occurs when an open book or magazine is scanned. The shadow created by the book's spine is detected based on its difference in color density, and the brightness is adjusted accordingly.