To meet the demands of the times, Canon continues to pursue laser printer and multifunction printer (MFP) development while striving not only to improve such basic performance aspects as image quality, speed, and ease of use, but also providing network compatibility, extensibility, and eco-friendly performance.

2018/12/27Featured Technology

Laser printers / laser multifunction printers (MFPs), office multifunction devices (MFDs), and digital production printing systems all employ the same printing principle.

1 Charging

The photosensitive drum surface is negatively charged with a static charge.

2 Exposure

Laser beams scan the photosensitive drum to form an image. Areas exposed to the laser beams lose their electrical charge.

3 Developing

Toner is brought in close proximity to the drum and affixes to non-charged areas.

4 Transfer

The photosensitive drum is brought into contact with the paper* and a positive charge is applied from behind, transferring the toner onto the paper.

5 Fixing

Heat and pressure are applied to fix the toner to the paper.

#Physics

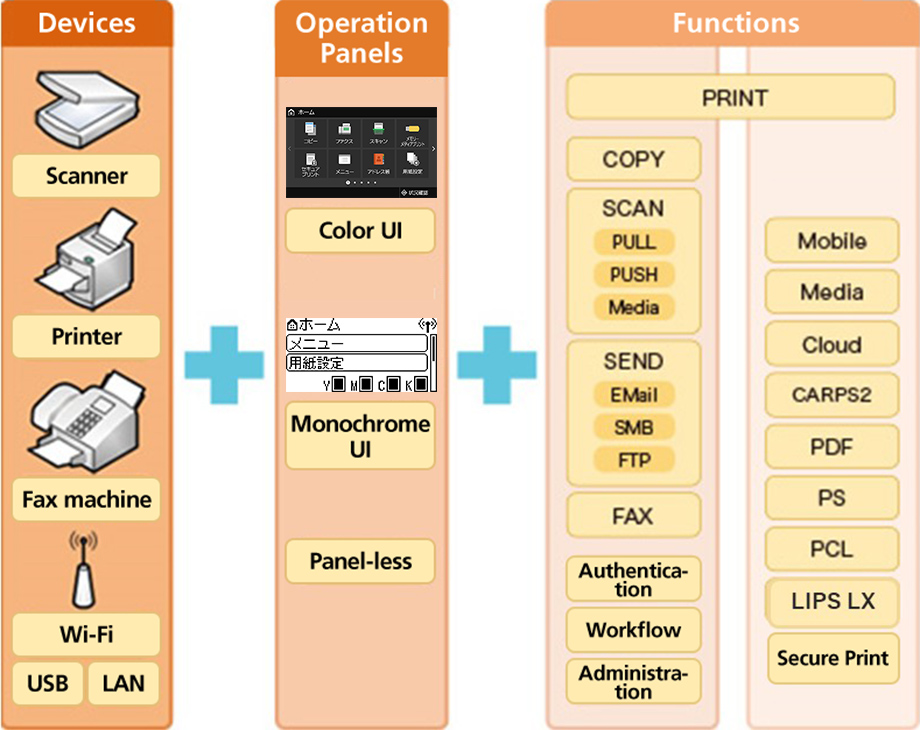

Canon has developed a lightweight, compact architecture that makes it possible to freely combine devices, operation panels, and functions into a full range of products, from single-function to multi-function printers, at low cost and in short development cycles.

Using this architecture makes it possible to freely combine devices such as scanners and printers, operation panels, and functions such as copying, printing, and scanning to create products.

This architecture groups individual devices and functions into block structures that can be easily combined into larger, more elaborate structures to create various models. The blocks are also interchangeable and can be easily diverted from one structure to another to help improve both development efficiency and product quality. This development environment also supports enhancements by making it easy to add such new functions as mobile printing and authentication.

In addition, Canon's free configuration architecture is equipped with a completely isolated language-dependent block capable of simultaneously supporting product development in more than 30 languages.

Conceptual Diagram of the Free Configuration Architecture

#Automation#Mechanical engineering#Electrical engineering#Computer science#Physics

Laser printers and MFPs are used not only for printing on paper, but also on a wide variety of other media, including resin film. Because the optimal amount of heat used to fix toner to the media varies depending on the media type, users must select the type of media they are using via a computer or from the printer's control panel. If too little heat is applied, the four colors of toner (cyan, magenta, yellow, and black) will not fully fuse to the media, resulting in poor image quality or a printout that peels easily. Conversely, if too much heat is applied, it can affect the media itself, causing it to bend.

Canon's newly developed, highly sophisticated automatic media sensing technology eliminates the inconvenience of changing printer settings manually as well as the risk of compromised print quality caused by configuration mistakes.

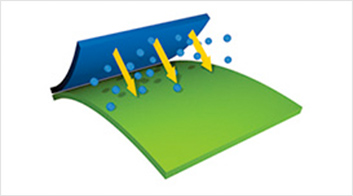

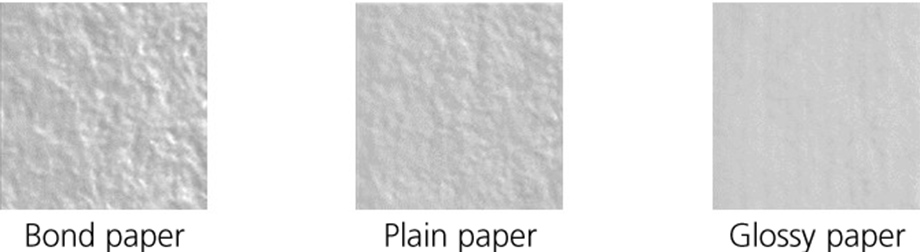

First, the surface of the media fed from the tray is illuminated by an LED and photographed by a CMOS sensor to measure bumps in the surface. Next, the media is bombarded with ultrasonic waves, and the paper weight1 is measured based on the ultrasonic waves that pass through. These two types of information are compared to data stored inside the printer's data library, and the printer automatically determines which of six types of media2 is being used, enabling printing with optimal settings for that media type. Using ultrasonic sensors makes possible higher precision media sensing compared with conventional products.

The data library used to automatically determine the media was made by analyzing the surface images of several thousand media types. Laser printers and MFDs with automatic media sensing technology offer stable, high-image-quality print performance regardless of the media used, and without inconvenience to the user.

How the Type of Media Is Determined

CMOS Sensor and Ultrasonic Sensors

Media Surface Images

#Mechanical engineering#Electrical engineering#Physics#Environmental awareness

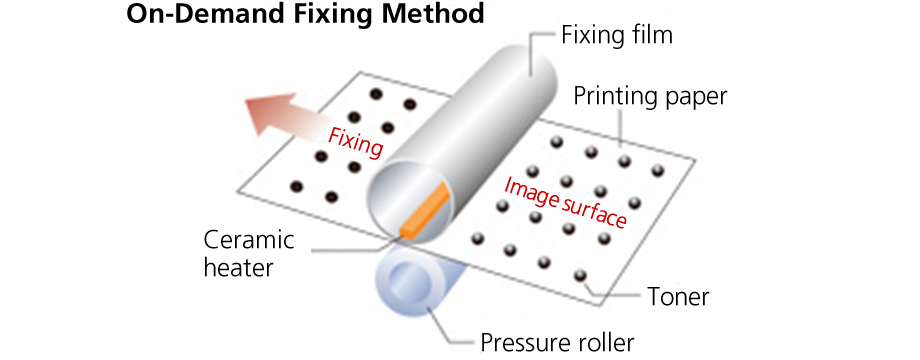

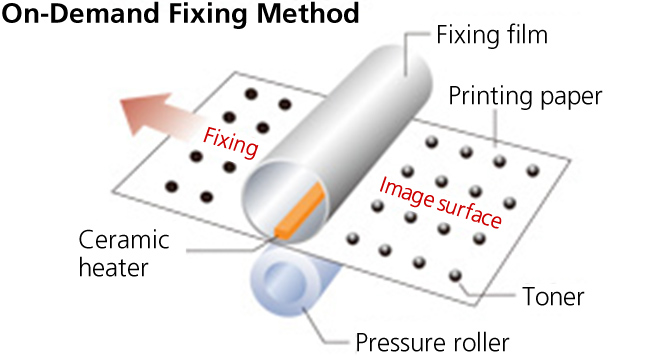

For laser printers and MFPs, heat is applied to melt the toner powder, and then a pressure roller is used to apply pressure and fix the toner to the media.

The fixing technology widely used until now involved using a halogen heater built into the fixing roller to apply heat (radiant heat) to warm it. However, when using this method, the fixing roller was slow to heat up. As a result, not only did it take longer to start printing, it was also necessary to constantly apply heat to the fixing roller while the printer was on standby. Canon tackled this issue early on and developed an on-demand fixing unit comprising fixing film with a low thermal capacity and a ceramic heater used to apply heat directly to the film. Because Canon's on-demand fixing technology eliminates the need to apply heat while the printer is on standby, and because heat is instantaneously applied when the heater is activated upon receiving a printing command, the technology makes it possible to reduce the time until printing starts from several minutes to several seconds. In addition to achieving a high-speed FPOT (First Print Out Time: the time until the first sheet of media is printed), this revolutionary technology eliminates the power consumption formerly necessary to apply heat while the printer was on standby, thereby significantly reducing energy costs. Canon is continuing to pursue the development necessary to further increase this speed and incorporate its on-demand fixing technology into its full range of print products.

Color On-Demand Fixing Technology (1 minute, 34 seconds)

*In order to view videos, it is necessary to consent to the use of cookies by our website. If the videos are not displayed, please click the "Cookie Settings" and accept cookies.

#Mechanical engineering#Electrical engineering#Physics#Environmental awareness

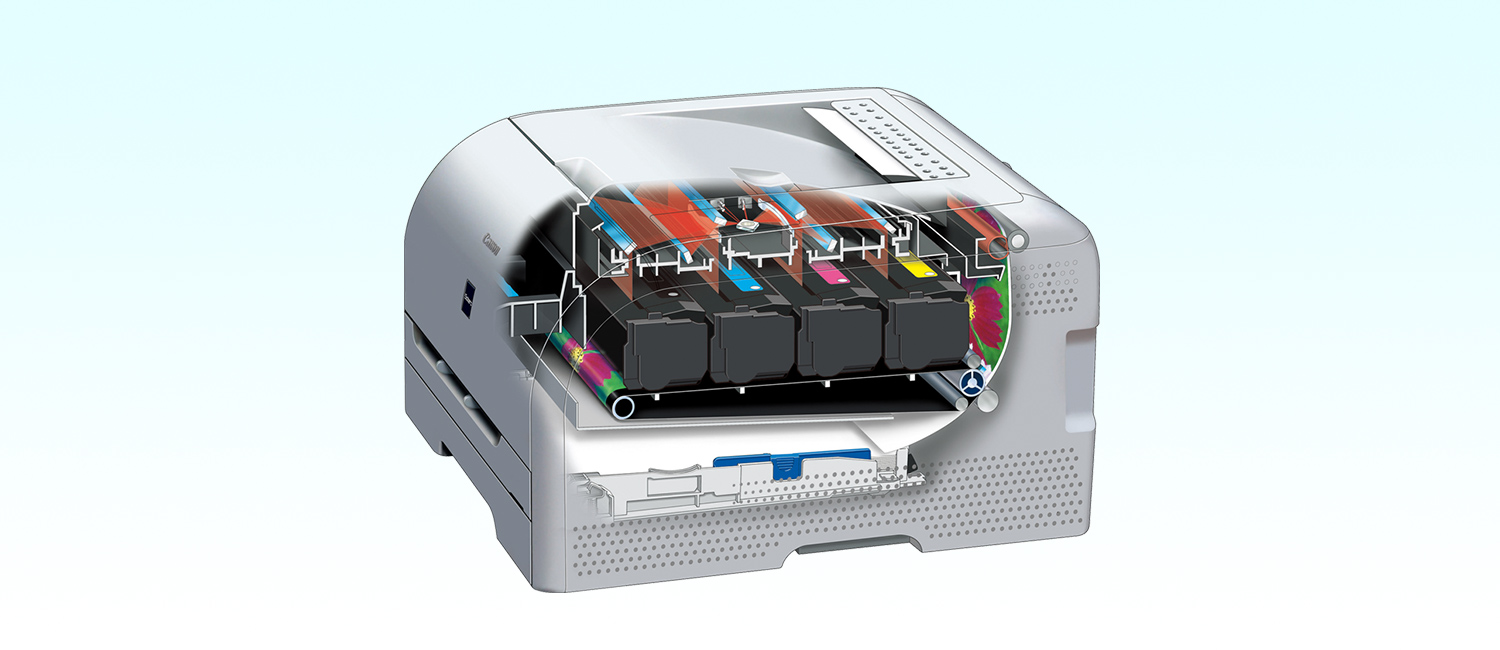

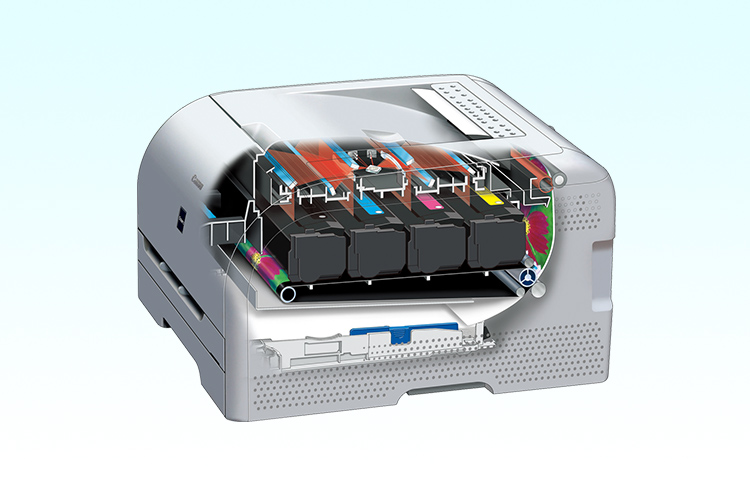

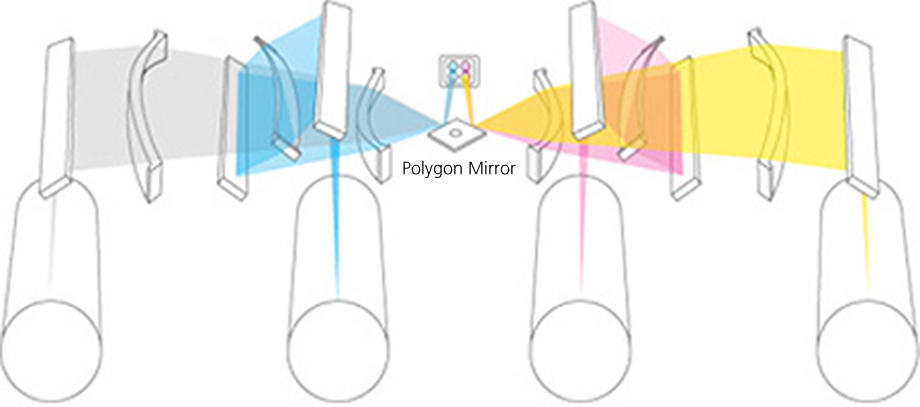

A laser scanner is a device that uses light to project an image onto a photosensitive drum. With conventional laser scanners, each of the four photosensitive drums requires its own laser scanner. Canon's 4-in-1 Laser Scanner is a single scanner unit that projects four laser beam colors onto a polygon mirror at oblique angles, splitting the light path into four directions to guide each beam towards its respective photosensitive drum. Positioning the polygon mirror at a low level in the center of the scanner unit and meticulously designing the paths of the beams made it possible to develop a 4-in-1 Ultra-Slim Laser Scanner achieving a minimal overall height for laser printers and MFP bodies.

4-in-1 Ultra-Slim Laser Scanner