News Release

Toray Industries, Inc.

Canon, Toray develop industry's largest bio-based plastic exterior part for use in multifunction office systems

TOKYO, October 14, 2010—Canon Inc. and Toray Industries, Inc. announced today the successful development of the industry's largest*1 exterior part made using bio-based plastic. The part, for use in Canon multifunction office systems for production printing, also achieves the world's highest level of flame retardance.*2

Plant-derived bio-based plastics, which curb increases in CO2 and decrease the consumption of oil resources, offer material properties that effectively reduce environmental burden. But because of the technological difficulties involved in realizing the moldability and other flow characteristics demanded of large-scale parts, while at the same time satisfying external appearance requirements and high mechanical strength and toughness criteria, bio-based plastics had proven difficult to adopt for use in exterior parts, particularly due to the high level of flame retardance required of such parts.

Through Toray's material design technology, capable of controlling polymer structures on a nanometer-order scale, and Canon's advanced molding technology, supporting the formation of large-scale parts, Canon and Toray realized improvements in material characteristics to successfully develop the industry's largest exterior part made using bio-based plastic.

The part, which measures 640 (w) x 440 mm (h) and weighs approximately 1,100 grams, will be used in Canon multifunction office systems for production printing. In terms of flame retardance, it achieves 5V classification under the UL 94 flammability testing program.*2 The newly developed part is approximately 11 times larger and approximately 6.5 times heavier than the previously realized largest bio-based plastic part*3 that achieved the same level of flame retardance.

Compared with conventional petroleum-based plastic, the new bio-based plastic developed by Canon and Toray offers an expected reduction in manufacturing-related CO2 emissions of approximately 20%.

This successful development achievement will enable the use of bio-based plastic in not only small-scale exterior parts in multifunction office systems and other business devices, but also for replacing large-scale exterior parts used in multifunction office systems for production printing.

Through continued technical development, Canon and Toray will work to realize further enhancements in the field of bio-based plastics with the aim of expanding the range of applications in which they can be used.

- *1As of October 4, 2010. Based on a survey by Canon and Toray.

- *2UL 94, the Underwriters Laboratories Standard for Flammability of Plastic Materials for Parts in Devices and Appliances, specifies the following classifications related to materials commonly used in manufacturing enclosures, structural parts and insulators found in consumer electronic products: (in descending order) 5V, V-0, V-1, V-2, HB.

- *3An exterior part employed in Canon imageRUNNER ADVANCE C9000 PRO/C7000/8000/6000-series models.

Reference Material

Canon and Toray collaboration on development of bio-based plastic

In October 2008, Canon Inc. and Toray Industries, Inc. announced the successful development of a bio-based plastic which includes more than 25% (by weight) a plant-derived component that achieves the world's highest level of flame retardance.

Because bio-based plastics do not perform as well as conventional petroleum-based plastics in such areas as flame retardance, impact resistance, heat resistance, and moldability, their use in multifunction office devices had been limited to a very few number of internal parts.

Canon and Toray, through the establishment of a new material design and molding technologies, were able to develop Ecodear,* a bio-based plastic that realizes improved material characteristics. Particularly in the area of flame retardance, Ecodear is the world's first bio-based plastic applicable for use in multifunction office systems to achieve 5V classification under the UL 94 flammability testing program.

This bio-based plastic is used in select exterior parts in the following five imageRUNNER ADVANCE series lineups: C9000 PRO/C7000/C5000/8000/6000.

The Canon imageRUNNER

ADVANCE C5051

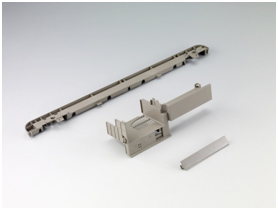

Example of exterior parts used in

imageRUNNER ADVANCE-series products

made from 5V-rated bio-based plastic

- *Ecodear is a registered trademark of Toray Industries, Inc. A plant-derived polylactic acid that, with the addition of Toray-proprietary technology, realizes significant improvements in flame retardance, heat resistance, impact resistance and moldability.