Industrial

Canon's super-precision technology is pushing the leading edge in semiconductors and displays.

Canon continues to support advanced electronics manufacturing

The electronics industry must innovate further to provide an abundant and sustainable society. At Canon, Optical Products Operations of Canon Inc., together with Group companies Canon ANELVA, Canon Machinery, and Canon Tokki, supplies production systems that cover many manufacturing processes for semiconductors, the technological base of all industries, and displays, an interface that connects people and IT. By honing its super-precision technology as a Group, Canon supports the advancement of manufacturing needed for society to progress.

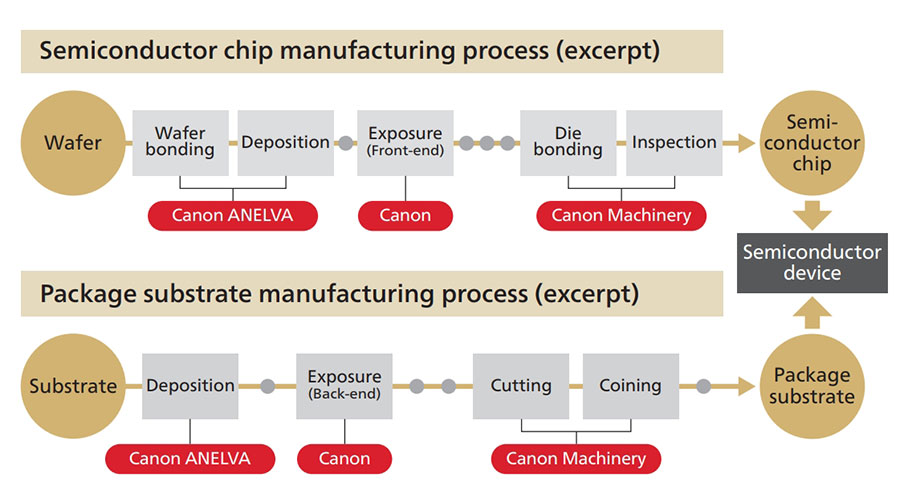

Covering a major part of semiconductor production processes

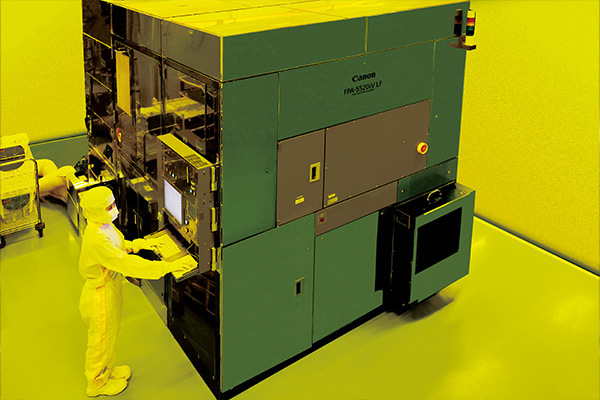

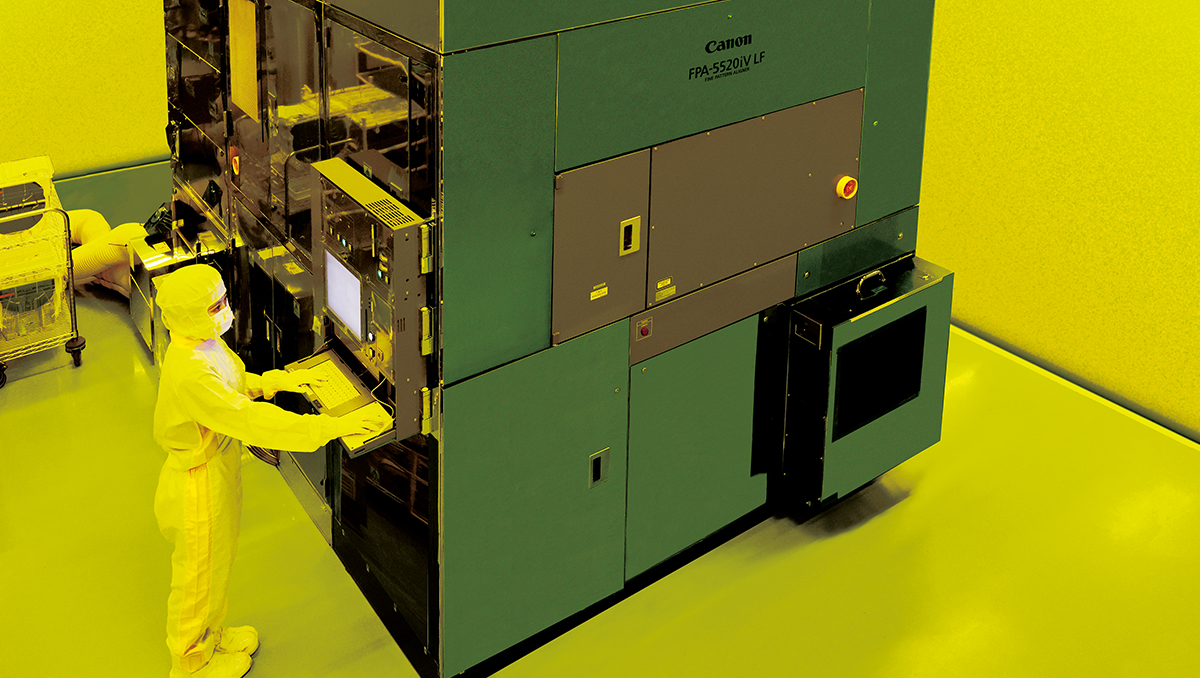

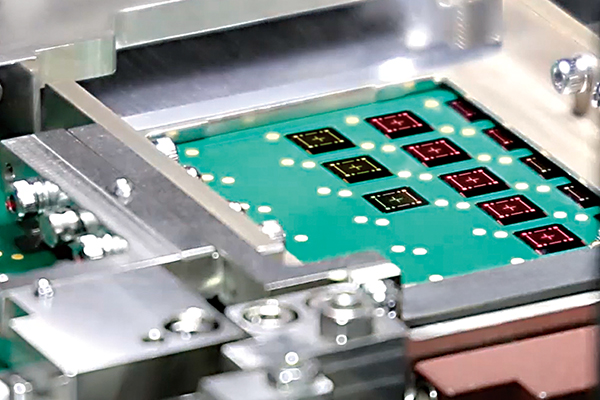

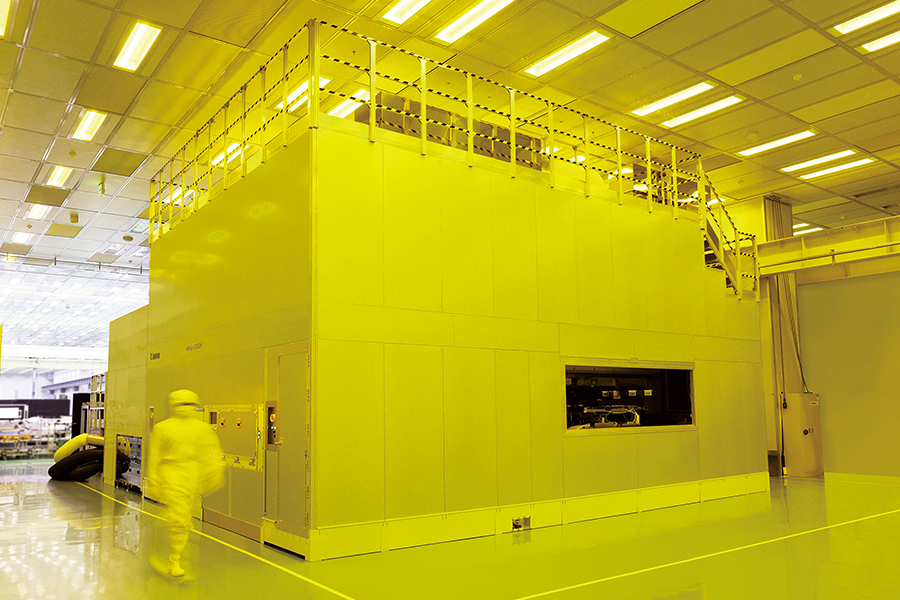

Canon contributes to many of the semiconductor production processes. For the lithography process, Canon's lithography equipment is used worldwide for mass production of power devices, for which demand is growing, and other semiconductors. The Industrial Group also offers nanoimprint technology for the production of superfine circuit patterns. For the film deposition process, it manufactures sputtering equipment that forms thin metal films, and for the chip bonding process, it manufactures die bonders that handle semiconductor chips. For high-performance packaging processes, which involve stacking multiple semiconductor chips or integrating chips with multiple functions, Canon enables larger chip integrations with its connecting lithography technology, which supports the soaring semiconductor production for AI applications.

Canon technology spearheads the production of various displays

Canon plays a vital role in the lithography and deposition processes in the production of LCD and OLED displays. Flat panel display (FPD) lithography equipment exposes display circuits on large substrates. With this super-precision technology, Canon supports the production of high-quality displays, from smartphones to large-screen high-definition TVs.

In addition to the lithography process for OLED display production, Canon was the first company to mass-produce deposition equipment necessary for layering organic materials on glass substrates. In these ways, Canon is assisting the evolution of displays.

Society realized by Industrial Equipment Business

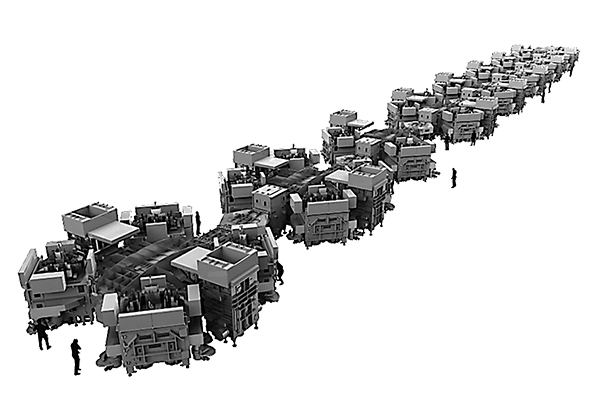

Canon's nanoimprint lithography can make the semiconductor manufacturing equipment much smaller and use much less energy thanks to its simple process.

LEARN MORE

Semiconductor lithography equipment plays a vital role in production of semiconductor devices and is counted on continuous operation. Canon’s new remote services contribute to high productivity.

LEARN MORE

flexible

Making displays even thinner, more beautiful, and energy-saving. Canon leads the world in the manufacture of OLED displays, which enhance convenience and offer even greater possibilities.

LEARN MORE

Canon Tokki boasts an overwhelming share of the manufacturing equipment that produces OLED panels used in smartphones and televisions. It supports next-generation manufacturing in cooperation with other Canon Group companies.

LEARN MORE

At the Kioxia Yokkaichi Plant, trials are underway for semiconductor lithography equipment that utilizes Canon's "nanoimprint" technology, which can significantly reduce manufacturing costs.

LEARN MORE