Technology in ProductsDie Bonders

A die bonder is a machine used during the back-end phase of the semiconductor fabrication process to complete semiconductor devices.

The rapid development of electric vehicles and generative AI technologies has spurred ever-increasing demand for semiconductors. In order to meet such demand, Canon supports the mass production of high-quality semiconductors with its automation technologies.

January 27, 2025

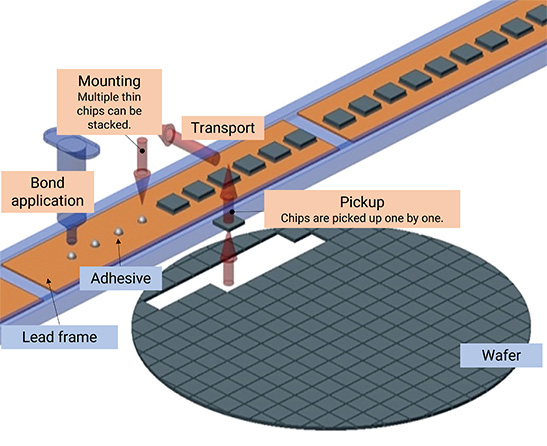

How a die bonder works

What is a die bonder?

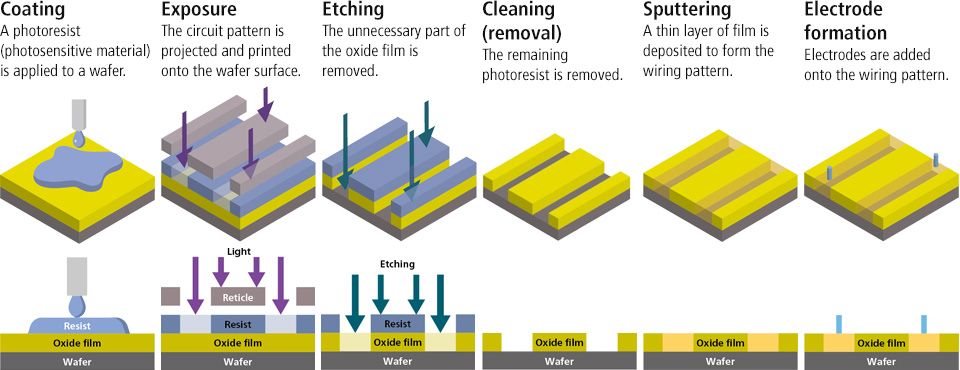

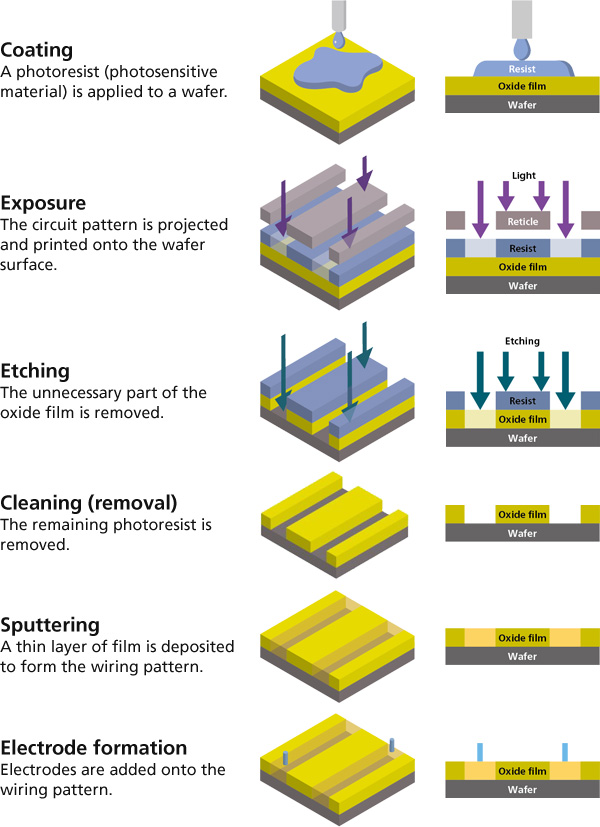

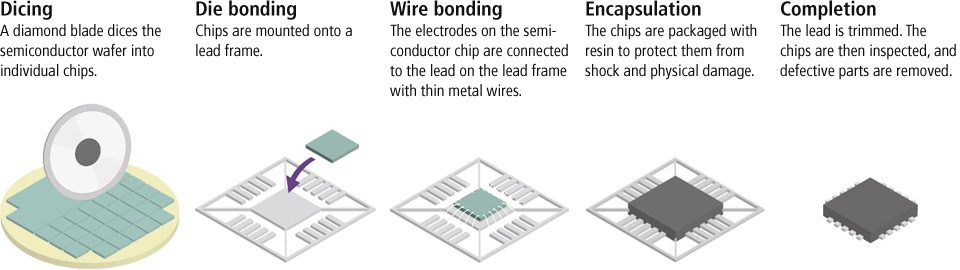

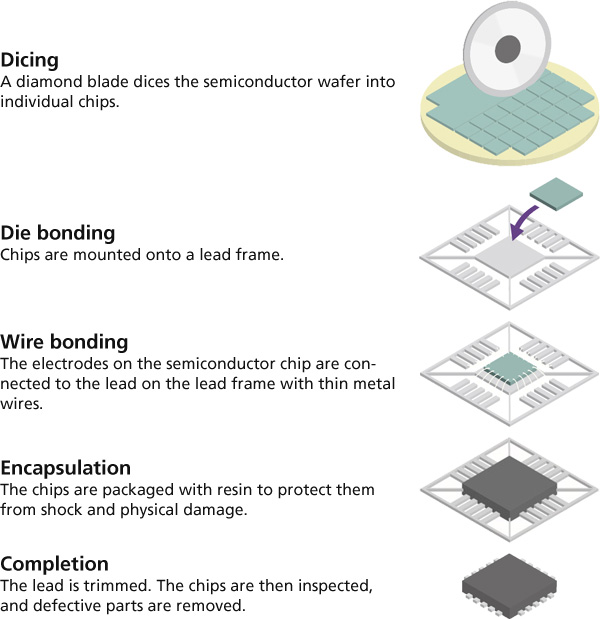

The semiconductor chip manufacturing process is divided into two phases: front-end and back-end. The front-end processing phase involves projecting a circuit pattern onto the surface of a semiconductor wafer so that it is printed onto the wafer, whereas the back-end processing phase involves dicing the printed wafer into individual chips and assembling them into completed semiconductor devices.

Read More

Canon’s die bonder technologies

Harnessing technologies that enable high-speed, high-precision semiconductor chip bonding

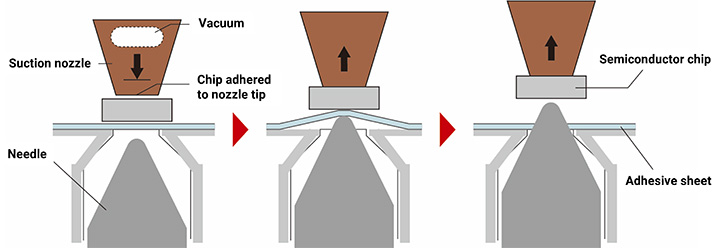

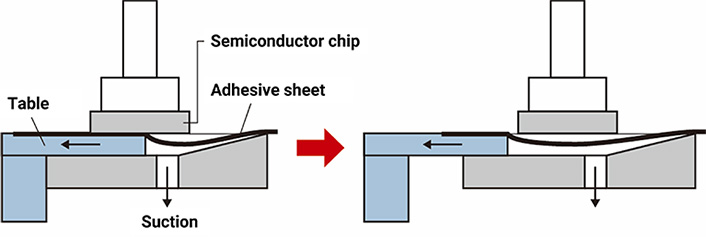

A unique technology that performs high-speed, damage-free semiconductor chip pickup

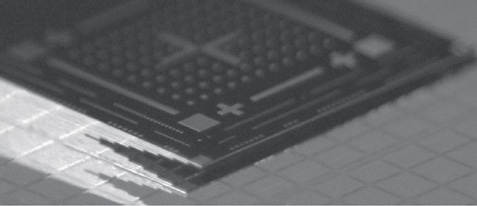

Canon developed a needleless pickup unit that can swiftly pick up semiconductor chips as thin as just over 20 micrometers without damaging or breaking them. It simultaneously suctions the adhesive sheet from below to peel it away from the semiconductor chip and slides the table so that the chip can be picked up.

The adhesive application technology that creates high-quality semiconductor products

Canon’s die bonders don’t just move semiconductor chips quickly with high precision, they also use bonding technologies that cater to diverse client needs. The type of adhesive used to mount the semiconductor chips to the lead frame depends on the client’s product, and also varies in viscosity (thickness). Die bonders use the optimal application amount, position, and pattern for each type of adhesive to ensure that it is applied evenly over the entire surface joining the semiconductor chip and lead frame. This technology keeps temperature rises on the semiconductor chip under control and prevents the chip from peeling off the lead frame, contributing to the high quality of precision equipment and other products that use semiconductors.

Examples of adhesive application patterns