News Release

May 27, 2024

Canon Inc.

Canon releases FPD lithography equipment for dashboard displays and smartphones

Will achieve higher yield through wider exposure

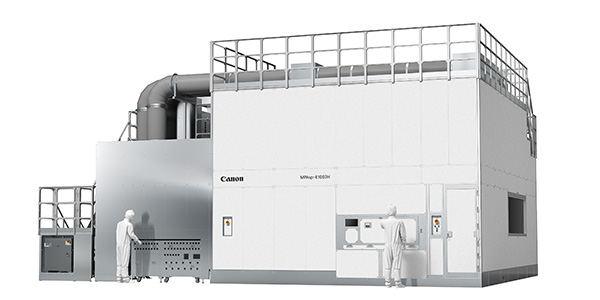

TOKYO, May 27, 2024—Canon Inc. announced today that the company will release "MPAsp-E1003H," a new FPD (Flat Panel Display) lithography system compatible with 6th generation substrates1 that achieves a high yield with wider exposure than previous models, in early June 2024.

(conceptual image)

Demand for vehicle displays has been diversifying and increasing in recent years due to advancements in automatic driving technology and the expansion of the market for electric cars. Display manufacturing equipment for vehicles or smartphones is required to be capable of not only producing high-quality products that are thin, light, and high-definition, but also achieving high productivity by efficiently mass-producing such products. The new MPAsp-E1003H will help to improve the efficiency of display manufacturing by combining wider exposure and improved overlay accuracy with new technology.

MPAsp-E1003H boasts enhanced yield thanks to the widest2 exposure on the 6th generation glass plate. Equipped with an optical system whose performance has been proven in the existing 8th generation substrate3 system MPAsp-H1003H (released in July 2022), which is capable of batch exposing 65” panels for such products as large-sized TVs, the new product's single exposure width at a high resolution of 1.5 μm4 (L/S5) has increased by approximately 1.2 times6. Smartphone displays, for example, which require six exposure shots per glass plate with the previous system, can be exposed with four shots, which helps to improve productivity.

Additionally, even extra-wide large displays specifically made for vehicles can now be produced in two shots without any stitching to achieve efficient mass production.

The new product also boasts high overlay accuracy. It deploys the same alignment system as the MPAsp-E813H 6th generation substrate system (released in September 2014), and is equipped with a newly developed non-linear correction REI (Real-Time Equalizing distorted Image) unit. Even with expanded exposure width, the new product realizes a high level of overlay accuracy (±0.30μm) thanks to the REI unit.

Another feature of the new system is its high flexibility. In order to be adaptable to diverse manufacturing processes while securing high quality production, the system inherits several proven mechanisms from MPAsp-H1003H including the illumination mode switching function that enables ultra-high resolution, slit illuminance control (SIC) technology that maintains consistent exposure linewidth, and a universal chuck that makes it possible to select the vertical or horizontal orientation of the glass plate best suited to the exposure layout.

- 1

Glass panels measuring 1,500 x 1,850mm, primarily used in the manufacturing of small- to medium-sized displays such as for smartphones

- 2

Among Canon-made FPD lithography equipment compatible with 6th generation glass panels

- 3

Glass panels measuring 2,200 x 2,500mm, primarily used in the manufacturing of TV display panels

- 4

Micrometer (μm): 1μm = one millionth of a meter = one thousandth of a millimeter

- 5

Line and Space. Refers to patterns in which lines and spaces are separated by consistent intervals

- 6

In comparison to MPAsp-E813H