What is Development and Design Platform?

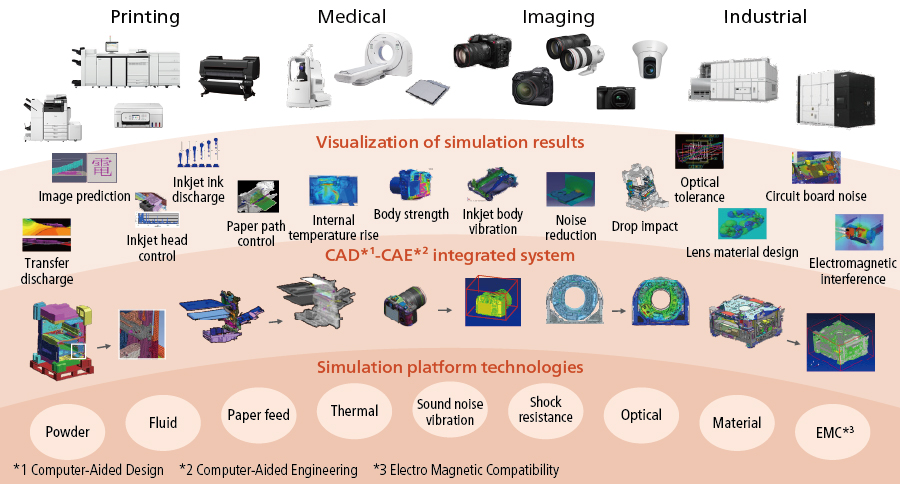

The “Development and Design Platform” is the technological infrastructure of Canon. It accumulates the technical expertise and know-how cultivated by Canon over the years for use with all products throughout the company. Examples include simulations for reproducing and testing physical phenomena from the micro to the macro scale, such as warping or undulation of paper, melting of individual toner grains, or the impact on a camera when the camera is dropped.

In conventional product development, a number of physical prototypes were produced based on drawings designed in CAD (computer-aided design) and used for repeated experiments and testing. This method placed a burden on product development in terms of cost and development time because we had to build many pieces of different prototypes for each stage of development.

The simulation technologies accumulated in Development and Design Platform is freely available to all engineers. By using them, engineers can check the accuracy and solve problems from the early stage of product development, reducing the time and cost of product development.

In addition to reduced material for physical prototypes, the platform also allows us to reduce the environmental impact of our product during transportation and use at our customers, for instance, making office multifunction devices smaller and lighter by optimizing the paper path inside them, and reduce power consumption by visualizing unnecessary heat generation.

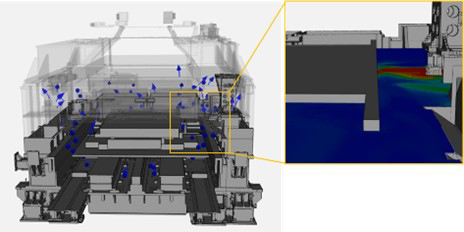

Predicting changes in temperature and airflows Simulation Technology for Flat Panel Display Lithography Equipment

Heat flow simulation is a technology for predicting changes in temperature and airflow inside products and equipment.

In manufacturing equipment for flat-panel displays, micro-sized circuits are printed on a glass substrate while being placed on a stage that moves the glass substrate inside the equipment at a high speed of 1 m/sec. For this reason, the accurate alignment of the stage is an extremely important point in rendering extremely fine circuit patterns. However, a problem has been that changes in the air temperature near the laser distance-measuring section* responsible for positioning can affect the accuracy of the exposure to light because, together with the temperature, the refractive index of the air changes and subsequently causes distance measurement errors.

By utilizing a heat flow simulation originally developed in the development of office multifunction devices at the design stage, we were able to minimize these temperature changes near the distance-measuring section, thus achieving the development of high-precision lithography equipment.

* A portion that accurately measures distance and displacement

Simulation technology for paper transport units in office multifunction devices enhances product quality

In the development of office multifunction devices, a CAE (computer-aided engineering) model is automatically generated from 3D CAD data using in-house developed automatic conversion technology, and the behavior of the internal paper path mechanism is reproduced virtually using in-house developed software. In this virtual environment, the paper movement in the paper path mechanism can be checked in detail without building a costly physical prototype. A product of higher quality can therefore be developed in a shorter period of time.

A variety of tasks can now be performed on the computer, making it possible to verify parts that would have been too small or hidden to see if they had been verified using a physical prototype. In addition, since almost all of the verification which could not have been covered by a single physical prototype can now be carried out virtually, the design quality can be improved with absolutely certainty.

*In order to view videos, it is necessary to consent to the use of cookies by our website. If the videos are not displayed, please click the "Cookie Settings" and accept cookies.