What are technologies that draw purposeful images and videos?

Technologies that draw purposeful images and videos refer to the technologies that enable various kinds of image drawing, such as vivid images on paper and microscopic circuits on glass substrates. In the printing field, since the release of the NP-1100, the first domestically produced copier, in 1970, Canon has provided copiers and printers, both for office and home use, that draw detailed text and high-resolution images on many types of paper media. And in the industrial field, we have developed and commercialized lithography systems that draw microscopic circuits on wafers and glass substrates. In the imaging field, we have developed a range of products that draw images and videos on displays, such as the electronic viewfinders (EVFs) for cameras. As Canon has diversified its business, we have created various image-drawing products for different types and sizes of objects that involve drawing.

Advantages of Canon’s technologies that draw purposeful images and videos

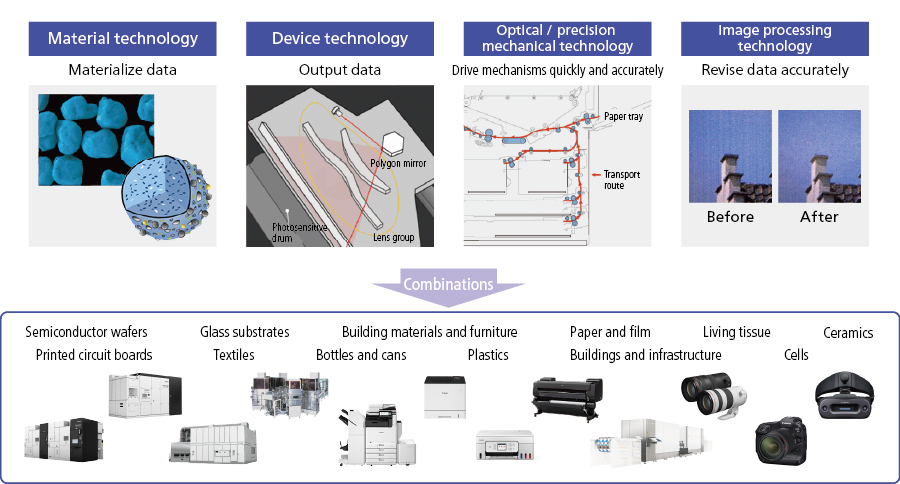

The main advantage of Canon’s technologies that draw purposeful images and videos is their ability to draw images quickly, accurately, and precisely on many types and sizes of objects. The basic drawing technologies can be summarized into four types: Material technology that gives substance to data; device technology that outputs data; optical and precision mechanical technology that drives mechanisms quickly and accurately; and image processing technology that revises data accurately.

Combining these individual technologies boosts the competitiveness of our products. For example, we develop from raw materials inks that have been optimized for the inkjet printer heads we develop in-house. This allows us to get the maximum performance from the printer head. Similarly, we get the maximum performance from our head-mounted displays that depict mixed reality by combining technologies for manufacturing high-definition OLED devices, OLED material technologies that express vivid colors, and image processing technologies that precisely overlay virtual spaces onto real spaces.

Application case study:

Group-wide effort develops a resist for nanoimprint lithography semiconductor manufacturing equipment

An example of a drawing technology that was realized by bringing technologies together across the Group is the development of a resist used in nanoimprint lithography (NIL) semiconductor manufacturing equipment.

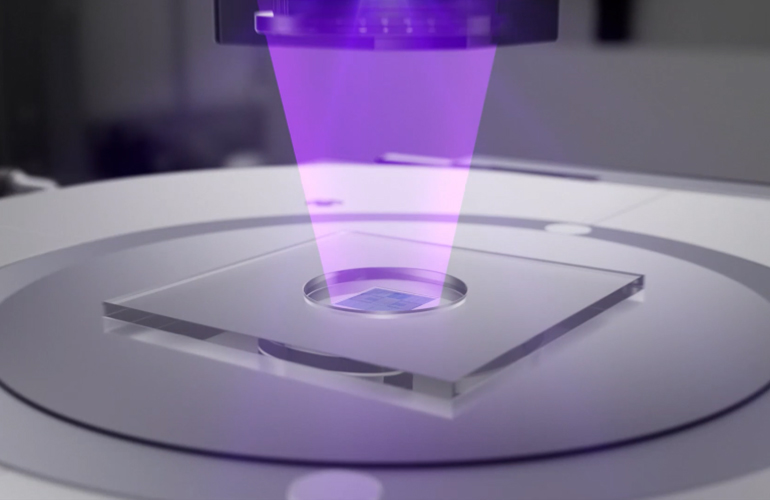

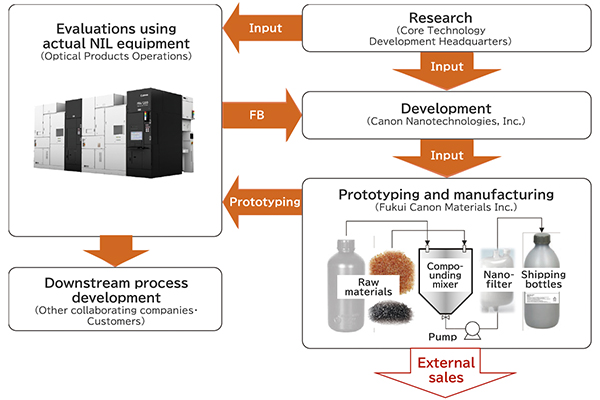

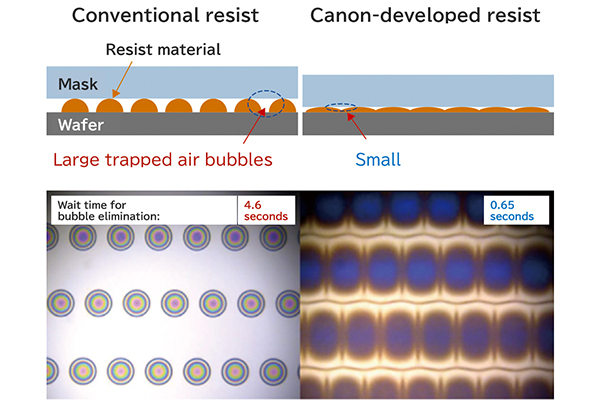

NIL draws semiconductor circuits with nanometer-level trace widths by dispensing droplets of liquid resist on the silicon wafer in accordance with the circuit pattern and then pressing and removing a mask etched with the electrical circuit pattern onto the resist. The compatibility of the resist and the equipment is extremely important, because the formed circuit pattern can be damaged while removing the mask. To create a resist optimized for NIL equipment, Canon created a collaborative framework in which the Group company Canon Nanotechnologies (located in Texas, U.S.) develops the resist, Fukui Canon Materials prototypes and manufactures the materials, and Canon evaluates the resist on the actual equipment.

The newly developed resist droplets spread over the wafer surface at a faster speed, greatly reducing the time required to eliminate air bubbles trapped in the droplets. This has led to a three-fold increase in processing speed.

More information about Nanoimprint Lithography:Nanoimprint Lithography

Related Links

R&D introduction PDF "THE CANON FRONTIER"

Technology