What is Manufacturing Platform?

Our Manufacturing Platform systemizes technologies that have been acquired and enhanced by Canon through past manufacturing experiences so that they can easily be applied throughout the company.

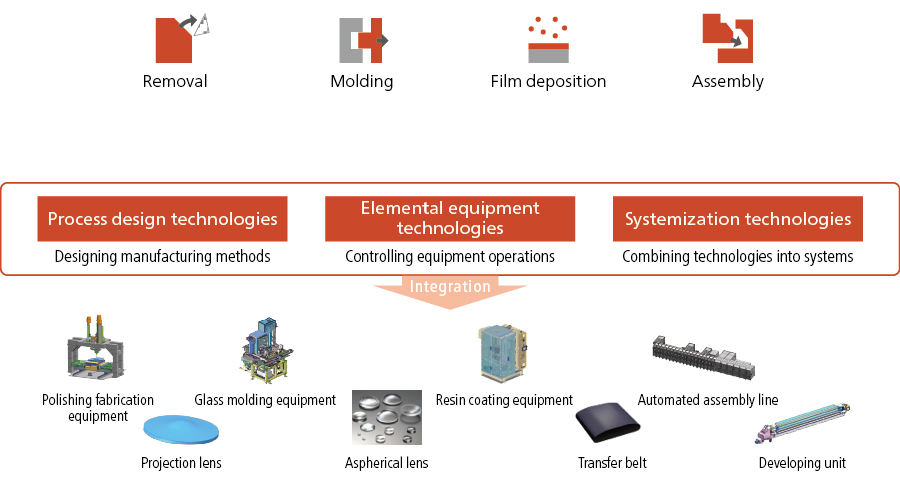

Advanced manufacturing technologies are essential to delivering attractive products to the world. At Canon, in the course of product-specific manufacturing, we have acquired and enhanced technologies for advanced manufacturing in four areas: removal, molding, film deposition, and assembly. We have categorized this stockpile of technologies into three main areas: process design technologies for developing manufacturing methods for components, elemental device technologies for controlling the operation of devices, and systemization technologies for integrating these technologies into systems. These technologies form the foundation of our manufacturing platform, which we utilize across the company to manufacture precision fabrication equipment and automated assembly equipment in house, as well as produce key parts and units.

Canon’s manufacturing strength lies in our ability to produce various devices in-house. Our automation technologies originated for the production of cartridges and other consumables. For example, automated assembly production has made it possible to minimize variations in assembly accuracy to a degree that was previously impossible. This allowed us to incorporate into our products complex designs that we had previously abandoned. In this way, automated assembly production has provided new value to customers. Such advances have been applied not only to cartridges but to all Canon’s businesses, including cameras, semiconductor manufacturing equipment, and medical equipment, letting us create products with greater added value.

Application case study:

A single automated device can assemble a wide variety of camera lenses

Automation equipment was originally developed for mass-produced items such as ink and toner cartridges, but its application has now expanded to include multiple small-lot items.

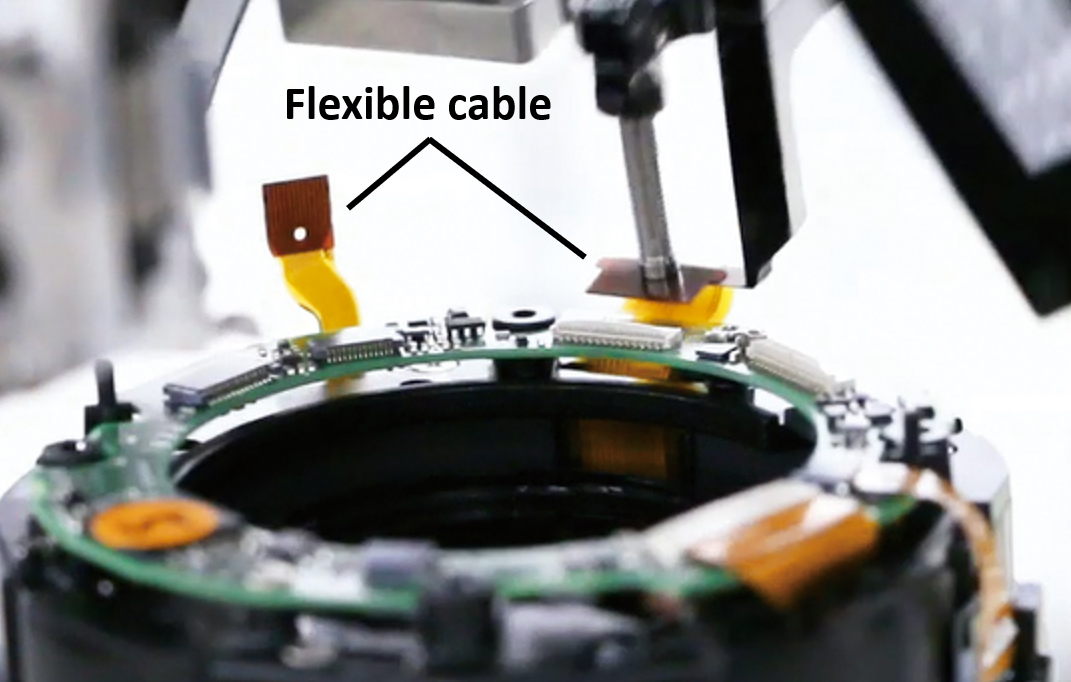

What sets Canon’s automation equipment apart is their high precision and fine-grained force control. One example is connecting flexible cables, which wire electrical modules together. Flexible cables are thin, delicate, and flexible, making it difficult to determine the exact position and timing to grasp them. Canon’s automation equipment, however, can bend these cables with precise force control and quickly and accurately connect them in the proper positions. This is made possible through technology that uses a camera mounted at the end of the robot arm that recognizes the positional relationship between the arm and the parts, as well as the distance between the modules to be connected, in real time, for precise control of the robot arm.

Highly sensitive sensors detect the slightest force applied to the tip of the robot arm, so the robot arm can handle processes requiring delicate force control with ease. Such advancements in automation technology have made it possible to assemble a wide variety of interchangeable camera lenses using a single automated device. This example demonstrates how Canon’s manufacturing platform technologies are a key source of product competitiveness.

Related Links

R&D introduction PDF "THE CANON FRONTIER"

Technology