Climate Change

Designing Energy-Efficient Products

Canon is making efforts to design energy-efficient products, to reduce CO2 emissions at customer use.

For example, for its office multifunction devices (MFD) and laser printers, Canon uses energy-saving technologies, including on-demand fixing technology and induction heating (IH) fixing technology to reduce the amount of electricity needed during operation. Furthermore, we continue to make technological advances aimed at expanding our lineup of energy-saving products. For example, we have begun employing low-melt-point toner in new products, enabling fixing at lower temperatures than traditional toner.

Energy-Saving Product Design

Environmentally Conscious Designs for Office Equipment

Canon's imageRUNNER ADVANCE DX C3900F series of MFDs use industry-leading low-temperature fixing toner that offers significantly improved fixing temperatures compared to conventional toners. As a result, they reduce power consumption by up to 15%*1 compared to previous models—an industry-leading typical energy consumption (TEC*2) value. This toner boosts transfer efficiency by controlling the shape of toner particles, resulting in less post-printing residue, meaning the same toner bottle can print roughly twice as many pages before it is returned. This reduces the amount of toner waste, notably in high-volume printing conditions, leading to lower environmental impact. The eco-conscious design extends to the use of replaceable parts*3 with longer lifespans that need replacing less often.

- *1 A figure applies only to A3 model. The previous models in this comparison are the imageRUNNER ADVANCE DX C3835F, C3830F and C3826F that launched sales in October 2021.

- *2 Typical energy consumption (TEC) is based on in-house comparison with MFDs qualifying for the International Energy Star Program (digital color copiers with copy, fax and scan capabilities printing at 25-35 pages/min); data as of August 1, 2023.

- *3 Intermediate transfer belt, secondary transfer outer roller

Calculation and Disclosure of Carbon Footprint of Products (CFP)

We utilize the LCA approach to help estimate the life cycle CO2 emissions of Canon products. Life cycle is divided into five stages (procurement of materials; production; transportation; usage and maintenance; disposal and recycling), and we utilize LCA to calculate GHG emissions for each stage, which are converted into CO2 equivalents.The CFP is a visualization tool, helping to identify emissions-intensive processes to help us design Canon products that are more energy efficient.

Additionally, to enable customers to select products with lower CO2 emissions, we work to disclose relevant information based on SuMPO EPD*1 under the SuMPO environmental labeling program of the Sustainable Management Promotion Organization (SuMPO). In 2024, through collaboration with our suppliers, we were able to incorporate and disclose their primary data in SuMPO EPDs.

Additionally, by taking advantage of the Carbon Offset Program utilizing CFP promoted by Japan's Ministry of Economy, Trade and Industry, we have put in place a system for the carbon offset*2 of GHG emissions throughout the product life cycle of our office multifunction devices and some production printer products to address customer demands. Offset CO2 emissions in response to customer demands totaled 1,129 tons in 2024.

- *1 The Ecoleaf program was renamed SuMPO EPD in April 2024.

- *2 Carbon offset involves initiatives in which a company strives to reduce its own greenhouse gas emissions, while offsetting amounts it cannot reduce by reducing or absorbing emissions elsewhere.

Products registered for SuMPO Environmental Labeling Program (Japanese website only)

https://corporate.jp.canon/sustainability/environment/customer/products/cfpProducts certified under Carbon Offset Program making use of CFP (Japanese website only)

https://corporate.jp.canon/sustainability/environment/customer/products/cfp-certifiedReducing Impact in Product Use

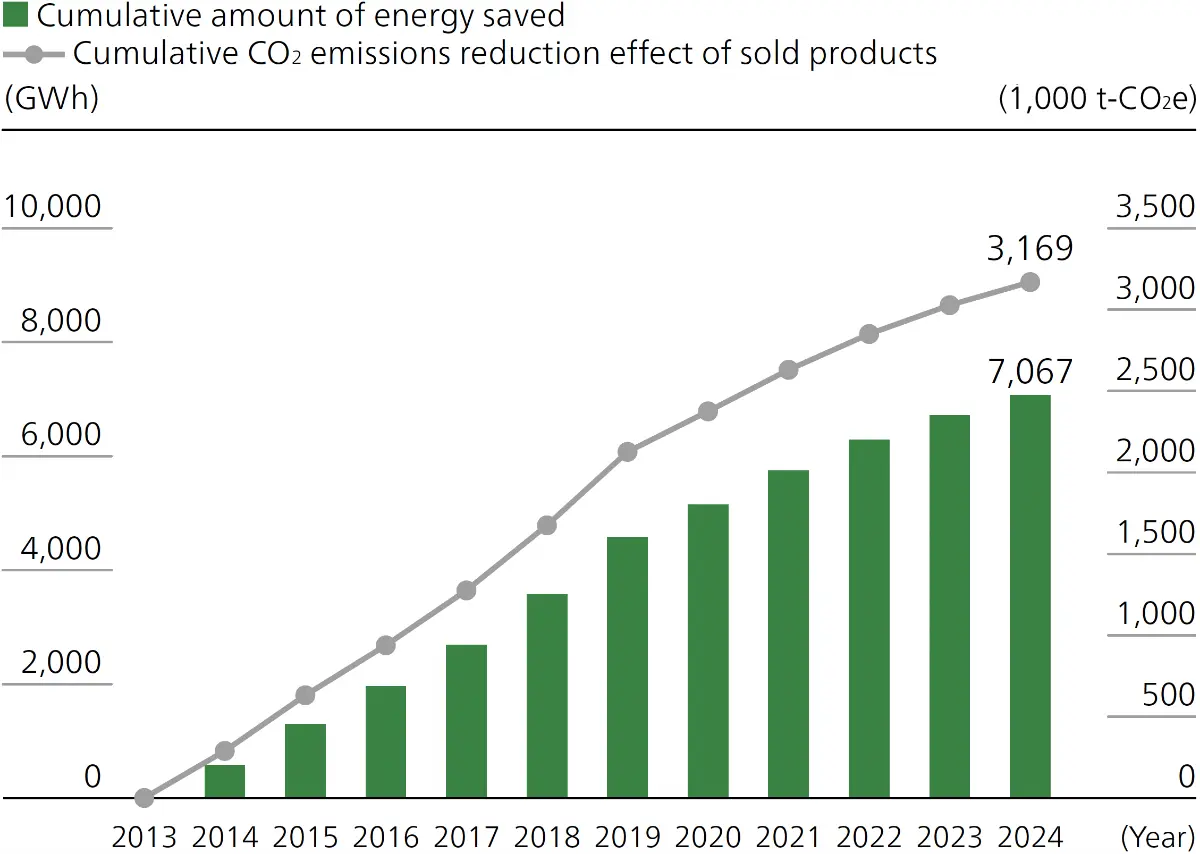

Thanks to energy-saving technologies used in office equipment, Canon products achieved cumulative energy savings of 7,067GWh between 2013 and 2024. This is expected to result in 3,169,000 t-CO2e reduction.

Energy / CO2 - saving Effects of Office Equipment (Cumulative)

- * Covered products: Electrophotographic multifunction devices and laser printers for offices (excluding production printers).

- * Energy-saving effect using the average energy (electricity) consumed by products sold five years prior to each respective year, assuming that products sold each year are in use for five years.

- * CO2 emissions factors are calculated by using the weighted average of sales per region based on emission factors published by the Federation of Electric Power Companies (in Japan) and the International Energy Agency (outside Japan).

Canon U.S.A. Named "Partner of the Year" at ENERGY STAR® Awards 2024

At the ENERGY STAR® Awards 2023, sponsored by the United States Environmental Protection Agency (EPA), Canon U.S.A. was selected as a "Partner of the Year-Product Brand Owner" for the ninth consecutive year. It additionally received, for the seventh consecutive year, the highest-level distinction of "Partner of the Year-Sustained Excellence Award."

Reducing Power Consumption and Environmental Impact in Cutting-Edge Semiconductor Device Manufacturing

In 2023, Canon launched the world's first commercial semiconductor lithography equipment using nanoimprint lithography (NIL) technology, which transfers circuit patterns using a method different from conventional photolithography technologies. While conventional semiconductor photolithography equipment exposes circuit patterns by using light onto the resist (resin) coated wafers, semiconductor lithography equipment using NIL technology transfers circuit patterns by pressing a nano-level mask (mold) with circuit patterns etched onto the resist coated wafers like a stamp.

Due to increasing demand for cutting-edge semiconductor devices, reducing the power consumption involved in semiconductor device manufacturing has become a key challenge in building a green society. Since NIL technology does not require a light source with a special wavelength for fine circuit patterns, it can significantly reduce manufacturing process power consumption down to approximately one-tenth that of conventional photolithography technologies. Furthermore, the elimination of the development process leads to the reduction of waste liquids and other materials, contributing to lower environmental impact.

This initiative has been highly regarded and received the top honor of the Grand Prize for the Global Environment Award at the 33rd Grand Prize for the Global Environment Award* ceremony hosted by Sankei Shimbun Co., Ltd in Japan.

- * Award program established in 1992, with special cooperation from the World Wide Fund for Nature Japan, for recognition of the industrial sector aimed at "coexistence between industrial development and the global environment." The program is supported by the Ministry of Economy, Trade and Industry, Ministry of the Environment, Ministry of Education, Culture, Sports, Science and Technology, Ministry of Land, Infrastructure, Transport and Tourism, Ministry of Agriculture, Forestry and Fisheries, Ministry of Internal Affairs and Communications, Japan Business Federation (Keidanren), and Japan Chamber of Commerce and Industry.

Contributing to Society by Reducing CO2 Emissions

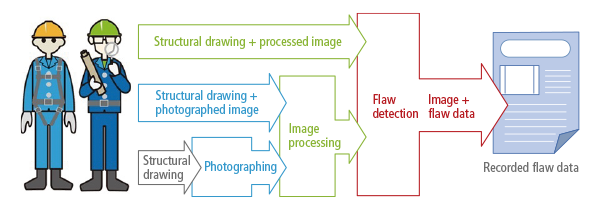

In addition to reducing life cycle CO2 emissions through hardware measures, we are deploying IT solutions to improve the efficiency of work operations, reduce the movements of people and objects, and realize resource and energy savings. This also promotes CO2 reduction in society as a whole. We are combining conventional visual inspection with high-resolution image capture, proprietary image processing, and AI technologies in the inspection of bridges and tunnels. By detecting cracks or other deformities using images of the structures, the system requires fewer workers and eliminates the need for physical movement of objects, enabling greater operational efficiency, realizing high performance, and reducing CO2 emissions.

By delivering a range of solutions to society, Canon will continue contributing to reducing CO2 emissions not only in its own operations but also in society as a whole.

Furthermore, with the recent advancements in IoT and the anticipated explosive increase in data processing due to AI utilization, there are calls for greater energy efficiency in data centers that consume enormous amounts of electricity. The Canon IT Solutions Group is promoting environmental activities in data centers with the aim of reducing CO2 emissions and protecting the environment through the data center business. More specifically, it is making improvements to daily operations in collaboration with customers, such as optimizing air conditioning efficiency and cooling water temperature, as well as coming up with better equipment layouts.

The Nishi-Tokyo Data Center has gained "top-level" facility accreditation for its outstanding global warming countermeasure efforts, as well as "S" class status under Japan's Act on Rationalizing Energy Use. Also, the Okinawa Data Center became the first in Okinawa Prefecture to run on essentially 100% renewable energy.

We have also donated CO2 reduction credits generated from our CO2 reduction activities.

Contributing to Energy Efficiency in the SACLA X-ray Free Electron Laser

SACLA is an X-ray free electron laser facility operated by the Japanese government research institute Riken. It enables real-time observation and analysis of molecular structure, making it highly useful in the development of pharmaceuticals and other materials. The power source for SACLA's electron beam accelerator is provided by klystrons manufactured by Canon Electron Tubes & Devices Ltd. Their product achieves energy savings of approximately 14% compared to the previous klystron product through improved microwave conversion efficiency, which has enabled a yearly saving of approximately 730 tons of CO2 for the facility as a whole.