Resource Efficiency

Recycling

Initiatives Regarding Consumables

Toner Cartridge Closed-loop Recycling

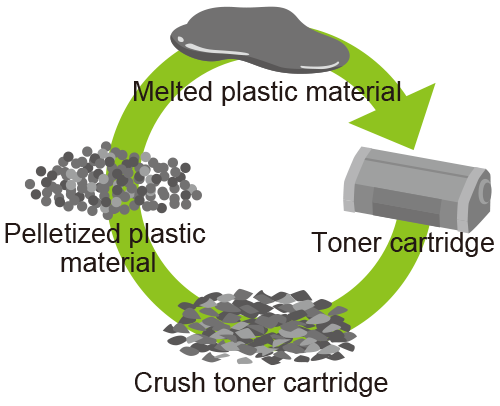

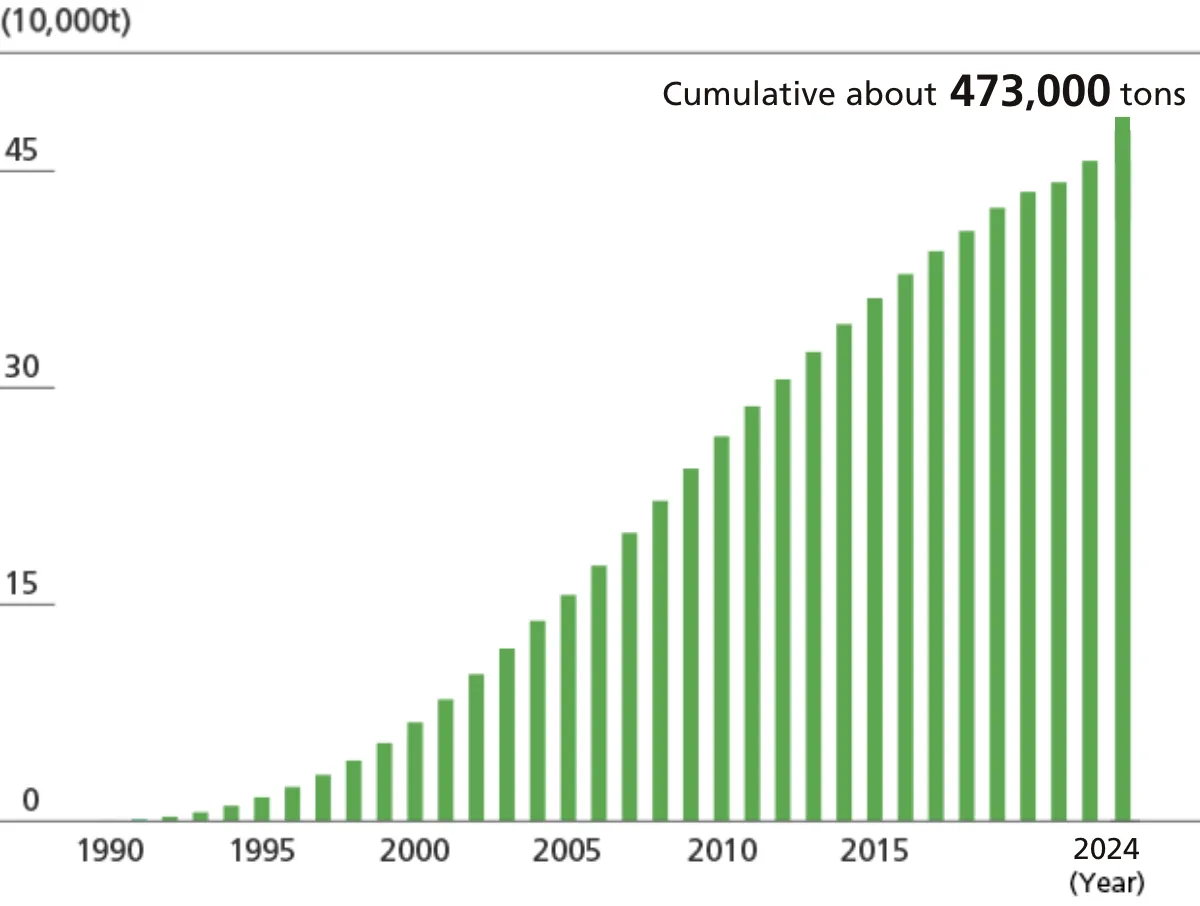

In 1990, Canon launched its Toner Cartridge Recycling Program, the first such program in the industry. The program continues to operate today. Returned used toner cartridges are brought to Canon recycling sites and sorted by model. The reusable parts are then picked out, washing and maintenance are performed, and the parts are reused in new products. Parts that cannot be reused are crushed and separated by material using physical characteristics such as electrostatic properties and specific gravity. The primary material of toner cartridges is the high-impact polystyrene (HIPS) used primarily for the housing. HIPS can be used repeatedly to make new toner cartridges, a unique feature of Canon's closed-loop recycling process. We conduct used toner cartridge collection in 24 countries and regions (with a cumulative collection volume of about 473,000 tons*1 as of the end of 2024) for recycling at four sites*2 worldwide. As of 2024 we have achieved a cumulative reduction in the use of new resources of approximately 340,000 tons*1.

- *1 Including OEM products

- *2 Japan: Canon Eco Technology Park, United States: Canon Virginia, France: Canon Bretagne, China: Canon Dalian Business Machines

Canon Automated Recycling System for Toner Cartridges (CARS-T)

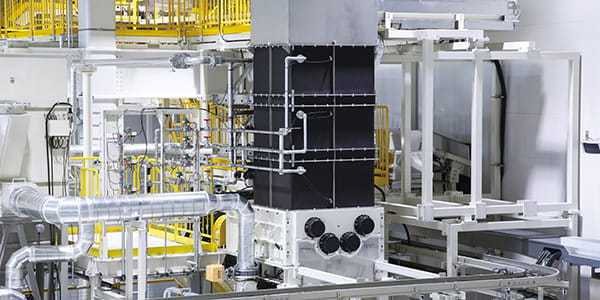

The Canon Automated Recycling System for Toner Cartridges (CARS-T) is a process whereby used toner cartridges are crushed and the materials automatically separated for recycling of the main component, high-impact polystyrene (HIPS). The sorting purity of the recycled plastic reaches 99% or greater* with the intensive use of various separation technologies at the different stages of the process.

A clean and silent operation, the CARS-T process also ensures there are no messy toner leaks from the sealed process units.

- * 99% or greater based on Canon's in-house sorting method

Collection and Recycling of Ink Cartridges

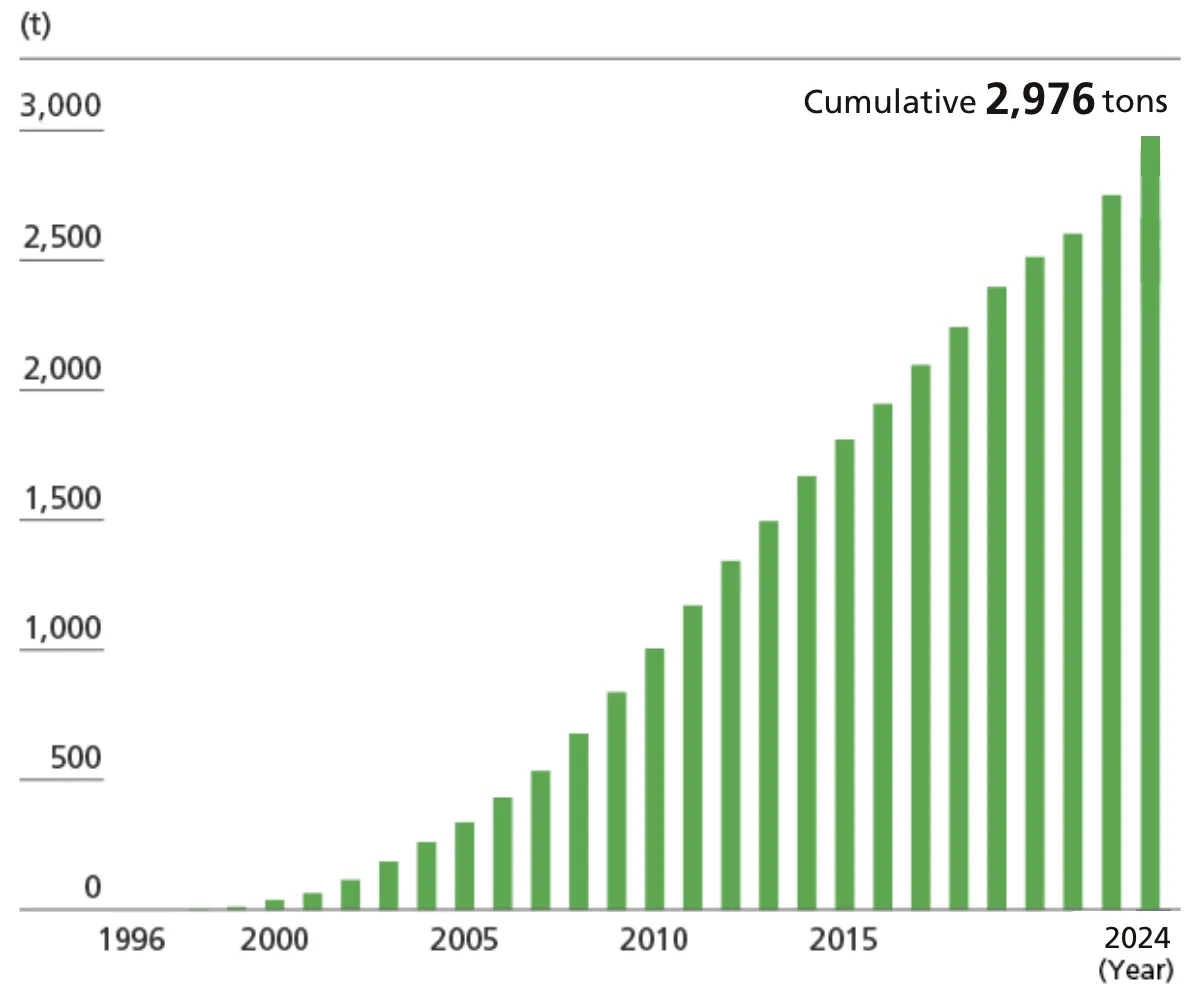

Canon has been collecting and recycling used ink cartridges since 1996. As of the end of 2024, the total volume of collected cartridges was 2,976 tons. In Japan, in conjunction with other printer manufacturers, Canon operates the Ink Cartridge Satogaeri (Homecoming) Project, a program that utilizes collection boxes for used ink cartridges in post offices, libraries, and other locations. Schools also collect cartridges through activities related to the Bellmark Campaign. Outside Japan, cartridge collection boxes are placed in large retail stores, companies, schools, and other locations. Collected cartridges are primarily closed-loop recycled as cartridge parts.

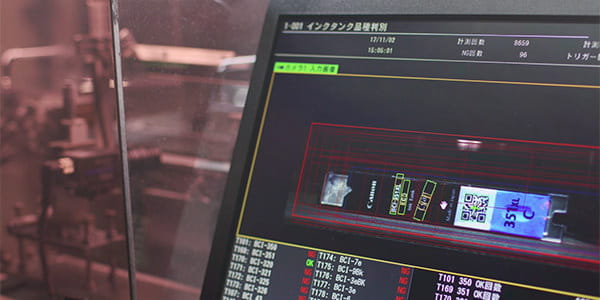

Canon Automated Recycling System for Ink Cartridges (CARS-I)

With the Canon Automated Recycling System for Ink Cartridges (CARS-I), a camera-based automatic sorting process is used on the used ink cartridges. The process line is automated, yielding an integrated process for the recycling of ink cartridges from disassembly and pulverization to washing. Separated materials are reused for ink cartridge components, materials for pallets used in logistics, or in stationery products.

Collection/Recycling of Used Toner Bottles

At the Canon Eco Technology Park in Japan, since 1998 we have been collecting used toner bottles and reusing them simply as containers and for the purpose of recycling the plastic materials.

Since 2022, Canon Bretagne in France has built a system for replenishing recovered toner bottles and supplying them to the regional market. This has not only further reduced the volume of plastic used, but also realizes energy savings at the point of toner bottle fabrication.

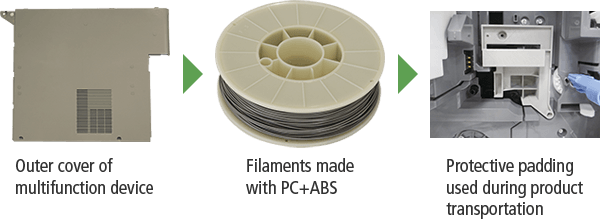

Development and Use of 3D Printer Filaments Made with Plastic Recycled from Multifunction Devices

As a new initiative to drive plastic material recycling, Canon Ecology Industry Inc. has developed a filament for 3D printers made with 100% recycled plastic. The recycled plastic raw materials used are PC+ABS and HIPS, which have a record of reliable performance as plastic materials and have been widely used in the outer covers and cassettes of multifunction devices and other applications. Adapting technologies accumulated through recycling of other Canon products, and utilizing optimal technologies to crush and wash the outer covers and cassettes of multifunction devices recovered from the market and then process them through extrusion-molding, enabled filaments with a stable wire diameter to be manufactured even with 100% recycled plastic.

In February 2018, we opened the Canon Eco Technology Park. Based on a "clean and silent" design concept, which overturns the traditional image of recycling operations, the facility has implemented advanced systems to further boost recycling efficiency. The Canon Automated Recycling System for Toner Cartridges (CARS-T) is a process in which, after separation using a camera-based process, used toner cartridges are crushed and materials automatically separated for recycling of the main component, high-impact polystyrene (HIPS). The sorting purity of the recycled plastic reaches 99% or greater* with the intensive use of various separation technologies at the different stages of the process. With the recycling system for ink cartridges (Canon Automated Recycling System for Ink Cartridges: CARS-I), a camera-based automatic sorting process is applied to used ink cartridges. The automated process line covers disassembly, pulverization and washing. Separated materials are reused for ink cartridge components and packaging. Resources that cannot be recycled in product-to-product recycling are diverted to material recycling or thermal recovery processes to help maximize resource efficiency.

Furthermore, to expand the production of recycled plastic materials, in autumn 2024 we introduced a Raman spectroscopy sorting device (manufactured by Canon) that is capable of sorting black plastic. The device was exhibited at the Circular Economy Expo in October 2024, where it demonstrated sorting plastic pieces by irradiating them with laser light to recognize each one, measuring their position and color, and then sorting them using an air jet.

- * 99% or greater based on Canon's in-house sorting method