News Release

May 27, 2021

Canon celebrates 50th anniversary of its first interchangeable lens for SLR cameras to employ an aspherical lens element

TOKYO, May 27, 2021—Canon Inc. announced today that this year marks the 50th anniversary of the release in 1971 of the FD55mm F1.2AL, the company's first lens for interchangeable-lens SLR cameras that employs an aspherical lens element. Aspherical lens elements are not only used in the company's interchangeable-lens SLR cameras, but also broadcast lenses, semiconductor lithography systems, telescope mirrors and a wide variety of optical products.

Aspherical lens elements

The FD55mm F1.2AL

Canon's first lens featuring an aspherical lens element

The F2.8 L IS USM zoom lens series

Aspherical lenses possess a curvature that is ideal for gathering light at a single point. From the F2.8 L IS USM zoom lens series for professional and enthusiast users—the RF15-35mm F2.8 L IS USM (released in September 2019), RF24-70mm F2.8 L IS USM (released in September 2019) and RF70-200mm F2.8 L IS USM (released in November 2019)—to the RF28-70mm F2 L USM (released in December 2018) which realizes a fast f/2 aperture across the entire zoom range, Canon's aspherical lenses help reduce various types of aberration and achieve high image quality.

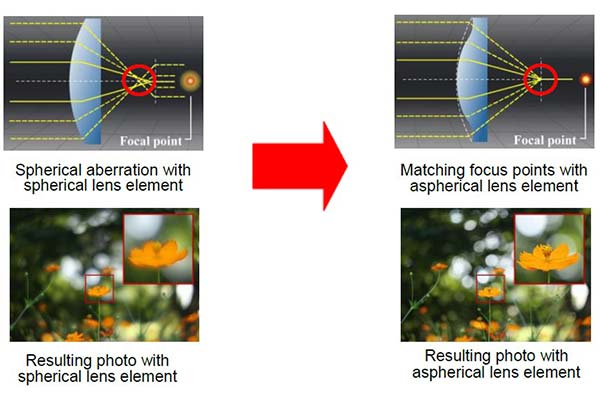

The inherent characteristics of spherical lenses result in the lens being unable to focus parallel rays of light in their complete form at a single common point. Due to the lens' spherical-shaped surface, blurring of captured images—known as spherical aberration—and other optical aberrations tend to occur in the captured image. In order to correct spherical aberration, multiple spherical lenses must be used and placed in a specific configuration. However, thanks to their unique properties, the same results can be achieved using only a single aspherical lens. In 1963, Canon embarked upon a program of sophisticated lens research and development in order to develop this "dream lens" that could focus all incident light on a single point and create a faithful, clear image.

In order to mass-produce aspherical lenses, Canon needed processing technology that was precise to within less than 0.1 micrometers1, as well as high-precision measuring devices that could measure to within 0.01 micrometers. Through repeated cycles of design and processing methods, the company finally succeeded in creating the technology needed to mass-produce aspherical lenses. In March 1971, Canon's first interchangeable-lens SLR camera employing an aspherical lens was released—the FD55mm F1.2AL. Then, in 1973, Canon further enhanced the precision of its lens processing technology with the development of the ALG-Z nanometer2 level ultra-high-precision aspherical lens grinder. The next leap forward happened in 1985, when the company successfully implemented the large-diameter glass mold (GMo) aspherical lens element into the New FD35-105mm F3.5-4.5 (released in December 1985), the world's first interchangeable lens for SLR cameras to include a GMo aspherical lens. Ever since, the technologies used to form and measure aspherical lenses have played a vital part in Canon's efforts to realize high-performance lenses.

Going forward, Canon will continue to polish its optical technologies in order to create products and technologies that help meet our customers' wide-ranging needs.

- 1One micrometer (µm) is one millionth of a meter.

- 2One nanometer (nm) is one billionth of a meter.

Aspherical Lens Processing Technology

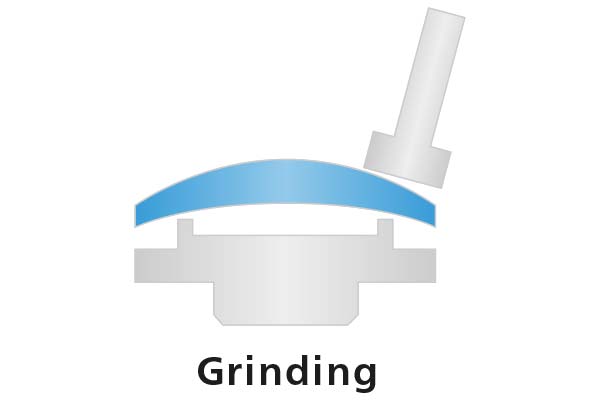

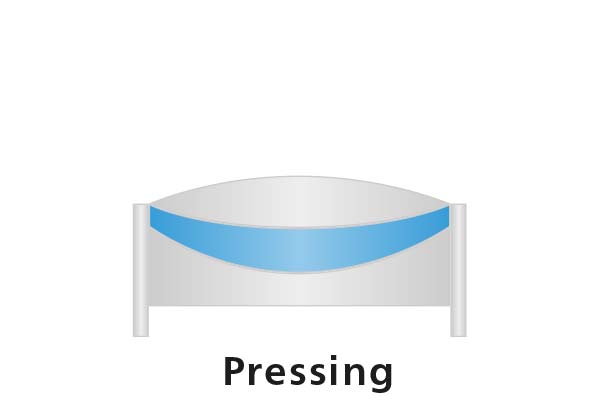

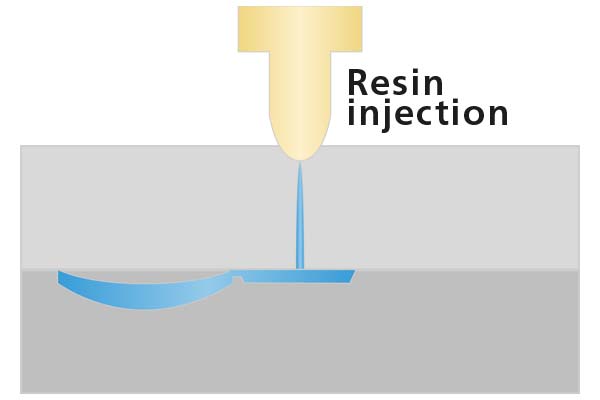

Canon's technological portfolio includes four distinct aspherical lens processing technologies. Aspherical lens grinding and polishing, which employs diamond-tipped tools to grind and polish the lens glass; aspherical glass molding, in which the lens glass is pressed and formed using an aspherical mold; aspherical replica technology that uses an aspherical mold to forms aspherical resin on the surface of spherical glass; and aspherical plastic molding, which injects and shapes resin inside an aspherical mold. Based on the properties of the aspherical lens element and its position in the lens' optical configuration, Canon will utilize the appropriate technology in order to produce lenses that are able to serve the wide-ranging needs of our customers.

Canon develops its lens processing machinery independently in order to realize the manufacture of aspherical lenses with a high degree of precision. To illustrate just how accurate Canon's technology is, only 0.1 micrometers' discrepancy is allowed between the dimensions of a lens' design schematic and the finished product. For a lens expanded to the size of the roof of the Tokyo Dome (diameter: approx. 244 m), this would mean a margin of error smaller than 0.5 mm, or the thickness of conventional mechanical pencil lead.

What's more, aspherical lens grinding and polishing technology—the most precise of the four technologies—is used not only in the production of SLR camera lenses, but also in the sciences. For example, the main camera optical correction system of the National Astronomical Observatory of Japan's Subaru Telescope features aspherical lenses made by Canon, using the company's high-precision measurement and processing technologies.

Canon's four aspherical lens processing technologies

Aspherical lens grinding

Aspherical glass molding

Aspherical replica

Aspherical plastic molding

The effects of aspherical lenses

Supposing an interchangeable lens comprising only spherical lens elements, such as large-diameter or wide-angle lenses, the presence of spherical aberrations and distortions greatly increases. Spherical aberration occurs when incident light parallel to the lens' optical axis, the position of the formed image when light rays are nearer to the lens' optical axis and images formed when light rays are further from the lens' optical axis are misaligned, resulting in a blurred image. In addition, distortions occur when the subject and the image formed by the lens fail to form identical images, causing straight lines to become distorted in the resulting image.

Thanks to their curved surfaces, shaped differently than those of spherical lenses, aspherical lenses are the solution to such problems caused by spherical lenses and therefore help produce ideally formed images.

- * Text in red edited on June 28, 2021.