News Release

October 25, 2024

Canon Inc.

Canon Ecology Industry Inc.

Canon honored at FY2024 3Rs Promotion Merit Awards for its initiatives to expand remanufacturing of multifunction devices

TOKYO, October 25, 2024—Canon Inc. and its subsidiary Canon Ecology Industry Inc. ("Canon Ecology") announced today that they received the METI Minister's Prize at the FY2024 3Rs (which stands for Reuse, Reduce, and Recycle) Promotion Merit Awards, hosted by the 3Rs Promotion Council, in recognition for their joint efforts to expand the remanufacturing of multifunction devices (MFDs).

Since 1992, Canon has conducted an MFD remanufacturing business which collects used MFDs and restores them with Canon’s proprietary technology to sell them as commercial products whose performance is equivalent to new ones. In Japan, Canon Ecology was established in 2004 as an environmental base to consolidate the reuse and recycling businesses of the Canon Group. Since 2005, it has conducted the Japanese side of the multifunction device remanufacturing business, for which Canon Ecology received the 3Rs Promotion Council President’s Prize in 2008.

This time, Canon received marks for achieving a high level of “environmental performance (rate of reused parts),” “quality and performance equivalent to new products,” and “low cost” in remanufactured MFDs, which are all crucial to continuing the MFD remanufacturing business for many years to come.

The achievement of these three goals is supported by two specific initiatives: “utilization of operational records” and “introduction of platform-based development.”

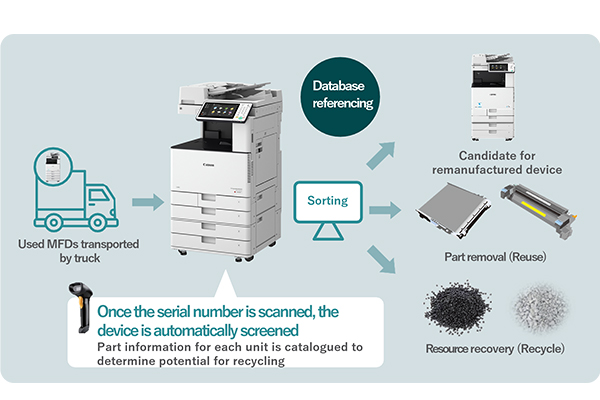

“Utilization of operational records” involves using a system to automatically determine whether or not certain parts can be reused based on data during the equipment’s operational use such as number of years in operation, part replacement history, and number of prints. The system generates a chart listing parts that need to be replaced. This chart is then used as a reference point when refurbishing the devices and contributes to maximizing the number of reused parts.

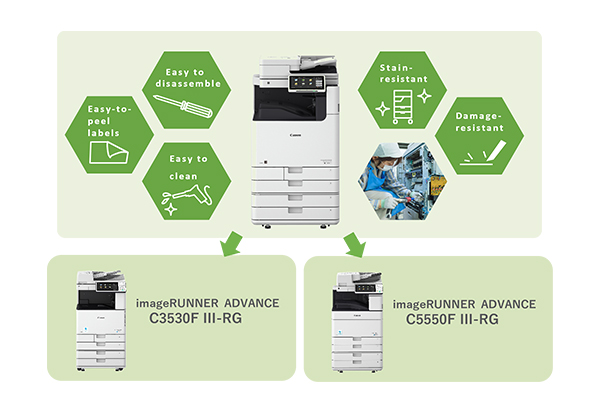

Under the “introduction of platform-based development,” Canon has fundamentally reformed its product development system to standardize the framework of the main units according to product class. This standardization applies not only to parts and units but also to processes such as disassembly and assembly, thereby realizing a product structure that can easily be remanufactured after collection.

These two initiatives integrally help to maintain the quality of remanufactured MFDs and improve the efficiency of the remanufacturing process, and have helped to raise the rate of reused parts to a maximum of roughly 95.5%1 in 2024.

Going forward, Canon will continue and expand its MFD remanufacturing business in order to help improve resource circulation.

About the 3Rs Promotion Merit Awards2

The 3Rs Promotion Awards have been held since 1992 with the goal of promoting a circular society. The awards encourage 3R-related activities by honoring companies and individuals that actively and continually make efforts towards reducing, reusing, and recycling waste and demonstrative outstanding achievements.

- 1

Achieved with imageRUNNER ADVANCE C3530F III-RG (released in August 2024)

- 2

For details, please see the following website (in Japanese only):

https://www.3r-suishinkyogikai.jp/commend/commend/