News Release

Canon commences sales of a new 'Grade 10' productivity upgrade option for FPA-6300ES6a KrF scanners that realizes industry-leading high-productivity standard of 300 WPH

TOKYO, June 13, 2022—Canon Inc. announced today that the company has commenced sales of a new "Grade 10" productivity upgrade option for its FPA-6300ES6a KrF semiconductor lithography equipment1. The upgrade makes possible throughput of 300 wafers per hour (WPH)2, the industry's highest3 level of productivity among 300mm wafer KrF semiconductor lithography systems.

FPA-6300ES6a

An FPA-6300ES6a system operating at a factory

Along with demand for semiconductor devices, demand is growing for semiconductor lithography equipment that offers increased levels of productivity. Since the launch of the FPA-6300ES6a KrF scanner in April 2012, Canon has continuously developed productivity-enhancing options, available as upgrades for existing units that have earned praise and a reputation of high-reliability from the market. When equipped with the newly available Grade 10 productivity upgrade option, the FPA-6300ES6a reaches productivity levels of 300 WPH. In addition, the company is planning to release an upgrade in 2023 that will enable the FPA-6300ES6a to also support 200mm wafers.

By increasing stage and transfer system speeds, the new Grade 10 productivity upgrade option greatly reduces exposure process time and achieves the industry's highest level throughput rate, 300 WPH. Additionally, by implementing a new stage control system that utilizes a neural network4—a first for Canon's semiconductor lithography systems—vibrations caused by high-speed stage movement are reduced, thus maintaining a high degree of accuracy. What's more, use of the new Grade 10 productivity upgrade option alongside the optional overlay accuracy upgrade, system owners can realize high-speed manufacturing with overlay accuracy as precise as 4 nanometers5.

The upgrade can be installed on users' existing FPA-6300ES6a6 systems currently in operation on mass-production factory floors. Since no replacements are necessary, productivity can be improved even further.

By continuing to provide a wide range of productivity-boosting solutions and upgrade options for its semiconductor lithography systems, Canon supports users' increasing productivity needs.

The Grade 10 productivity upgrade option will be available from Early August, 2022.

- 1A semiconductor lithography system that utilizes a 248 nm exposure wavelength laser generated by combining the noble gas krypton (Kr) and the halogen gas fluoride (F). One nanometer is equal to one billionth of one meter.

- 2Among 300mm substrate-compatible KrF scanners. As of June 12, 2022. Based on a Canon survey.

- 3The amount of 300mm wafers exposed in one hour at 96 shots per wafer.

- 4A form of machine learning patterned on the configuration of the human brain.

- 5 Single Machine Overlay

- 6FPA-6300ES6a systems with "Plus" option installed.

Reference

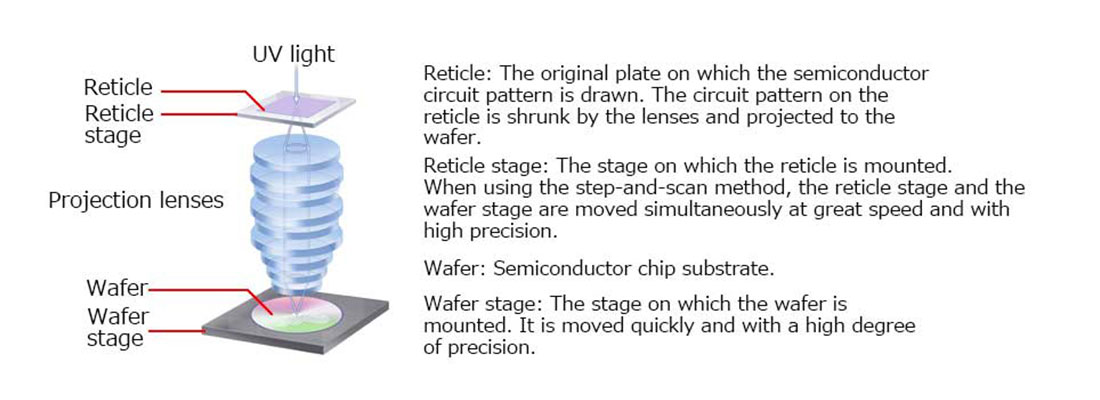

Scanners

Semiconductor lithography equipment that employs the "step and scan method," which involves simultaneously moving the reticle stage and wafer stage are commonly referred to as "scanners". While the overall system is more complex, the scanners are able to cover the entire expose angle via the scanning process. This enables the design of a smaller lens, resulting in less aberration and distortion, thereby simplifying the manufacturing process. This in turn results in greater exposure accuracy.

Canon semiconductor lithography systems

Canon manufactures an expansive lineup of semiconductor lithography systems, including systems utilizing KrF and i-line light sources, in order to serve a wide and growing range of customer needs for systems designed for wide-field or small-substrate production as well as production of devices for the internet of things.

https://global.canon/en/product/indtech/semicon/

The Canon Lithography System website and 50th Anniversary website

The "Canon Lithography System Website" features easy-to-understand explanations, including illustrations and videos, of the technologies behind semiconductor lithography, as well as a dedicated page for kids.

https://global.canon/en/product/indtech/semicon/50th/

https://global.canon/en/technology/semicon2021s.html