Resource Efficiency

Canon's Approach to Achieve a Circular Economy

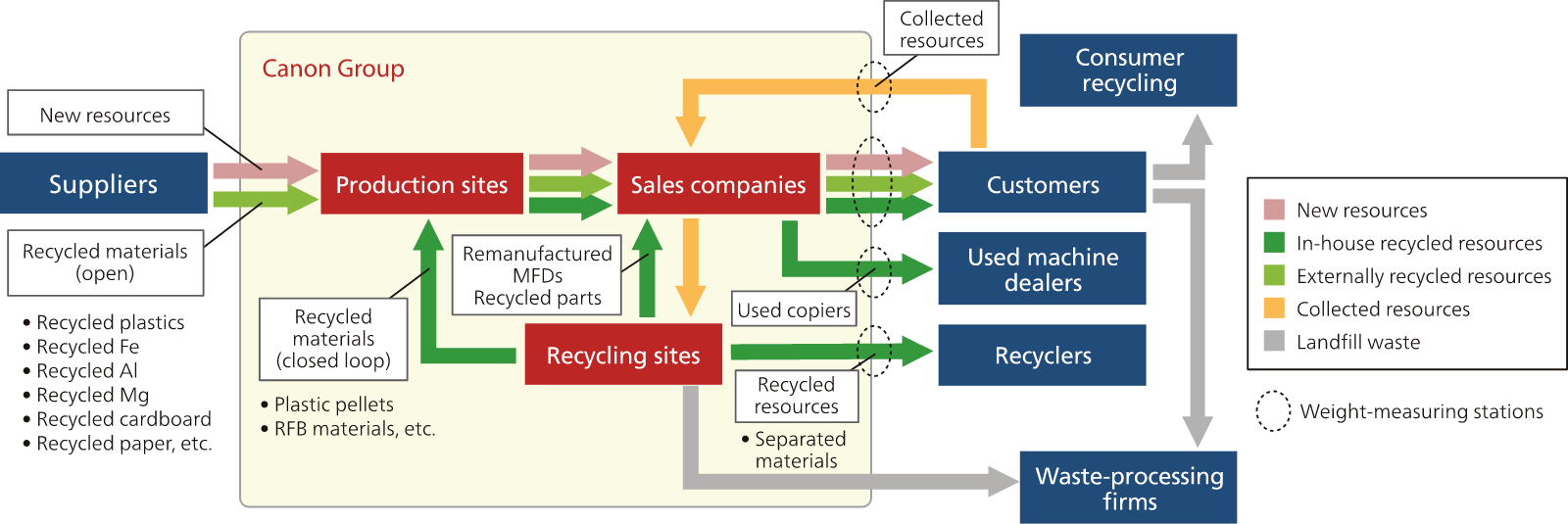

Flowchart of Resource Efficiency

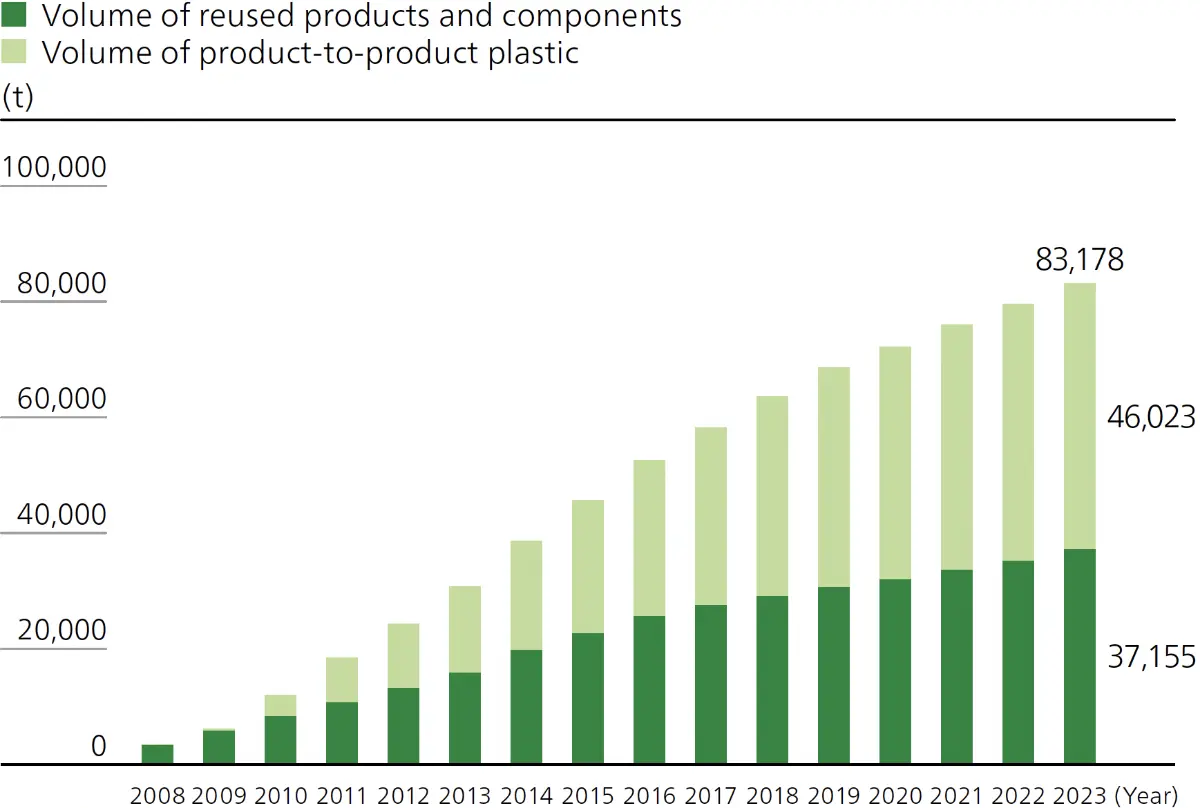

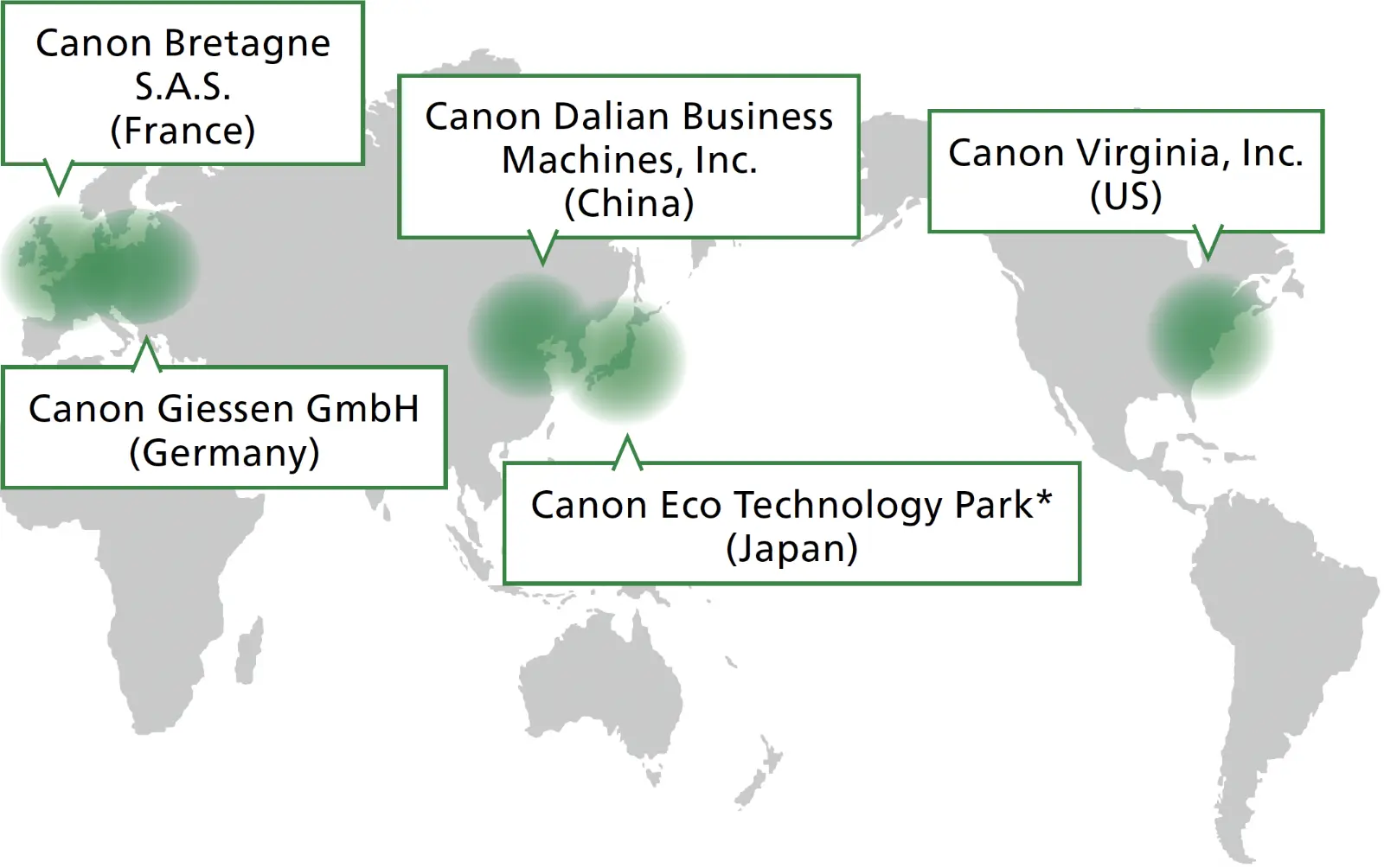

Canon seeks to recycle used products into new ones to maximize the value brought about by resource efficiency.In particular, we have emphasized such initiatives as closed-loop recycling of toner cartridges and the remanufacturing of office multifunction devices—collecting them post-use and making them into products with good-as-new quality. Currently, Canon has sites conducting recycling, in Japan, Germany, France, the United States, and China. We are continuing initiatives aimed at circulating resources within the same regions where they are consumed. Since 2008, we have reused 38,642 tons of products and parts directly and extracted 47,681 tons of plastic from used products for use as raw materials in new products. Going forward, we will continue to reinforce activities at Canon recycling sites around the world, contributing to both a resource efficiency and the realization of a carbon-neutral society.

- ※ Operated by Canon Ecology Industry Inc.

Digital Printing Business/Resource Recycling Targets Established

The resource recycling rate is a numerical figure indicating what proportion of the sales volume by weight of Canon's Printing Business utilizes recycled materials or components. We have set targets of 20% for 2025 and 50% for 2030, after recording a value of around 16% in fiscal 2022. The sales volume measures the aggregate weight of all Group inputs and outputs, including newly manufactured and remanufactured MFDs, toner and ink cartridges.

At Canon, we are taking the following initiatives to boost the resource recycling rate.

<In new machines>

- Incorporating recycled materials (recycled plastic and iron)

- Introducing and expanding easily recyclable platform-type designs

<At recycling sites>

- Developing technology geared towards improving the reuse rate of recycled machines and parts

- Improving the purity of separated recycled resources such as iron, nonferrous metals, and plastics

- Increasing the types and production volume of closed-loop recycled materials

Initiatives at recycling sites are being expanded from Canon Eco Technology Park in Japan, Canon's core recycling hub, to Canon Giessen, Canon Virginia, and other overseas recycling sites.

Actions in 2024 to improve reuse and recycling led to a resource recycling rate of approximately 17%.

Value Created by Resource Efficiency

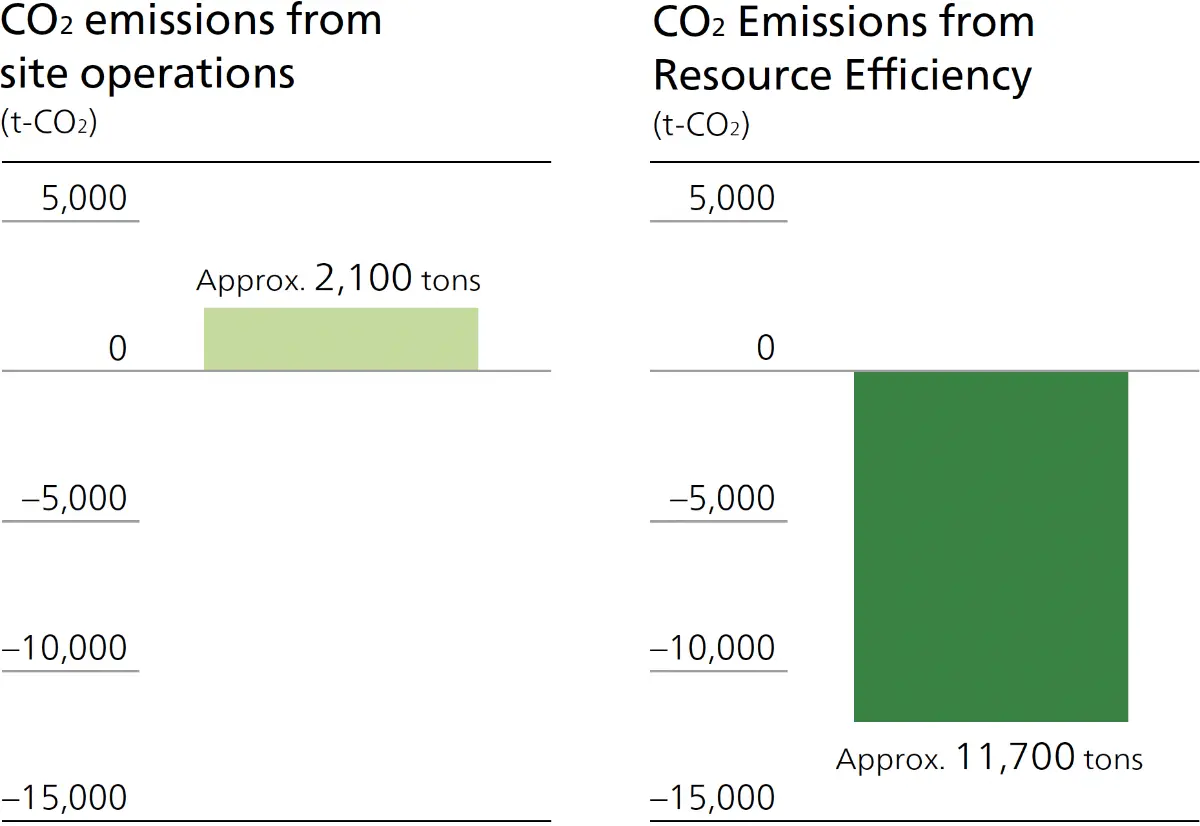

We see initiatives at Canon's recycling sites as not only contributing to a resource efficiency but also contributing to a carbon-free future. The reuse of parts through remanufacturing and the recycling of plastics through closed-loop recycling allow us to reduce the amount of CO2 emissions generated by raw material procurement and transportation compared with using new raw materials. Canon Eco Technology Park (operated by Canon Ecology Industry Inc.) emitted approximately 2,700 tons of Scope 1 and 2 GHG through site operations. We believe that these efforts have resulted in a reduction of approximately 14,100 tons of GHG emissions.

Environmentally Conscious Design

To make effective use of our limited resources, it is imperative that resource recycling is at front of mind in product design. Starting from the design and development stage, Canon gives careful consideration to the whole process through to collection and recycling of end-of-life products. Our Environmentally Conscious Design Guidance summarizes the various considerations that contribute to resource recycling, such as miniaturization, weight reduction, adoption of environmentally friendly materials, extending product lifespan, improving maintainability, and facilitating disassembly and separation for reuse and recycling. All of these items are incorporated into the design process.

Incorporating Recycled Materials (Recycled Plastic and Iron)

Canon has hitherto promoted the use of recycled plastic in some plastic parts used in multifunction devices and other products. In the new multifunction device imageFORCE C7165, released in November 2024, we achieved the use of over 30% recycled plastic by weight in the plastic materials used in the main unit.

Also, starting with new products slated to be released in 2025, we will be using recycled iron for the steel parts used in multifunction devices and printer parts.

As recycled plastic is made from waste plastic and recycled iron is made from iron scrap, the introduction of these recycled materials reduces the amount of new resources used and helps increase the resources recycling rate.

Regarding recycled iron in particular, Canon directly supplies iron scrap obtained from dismantling its used multifunction devices and printers to recycled iron manufacturers. By using the recycled iron produced by these manufacturers, Canon is involved in the entire resource recycling process, thereby facilitating the circulation and effective use of limited resources.

(with optional attachments)