Resource Efficiency

Remanufacturing of Multifunction Devices

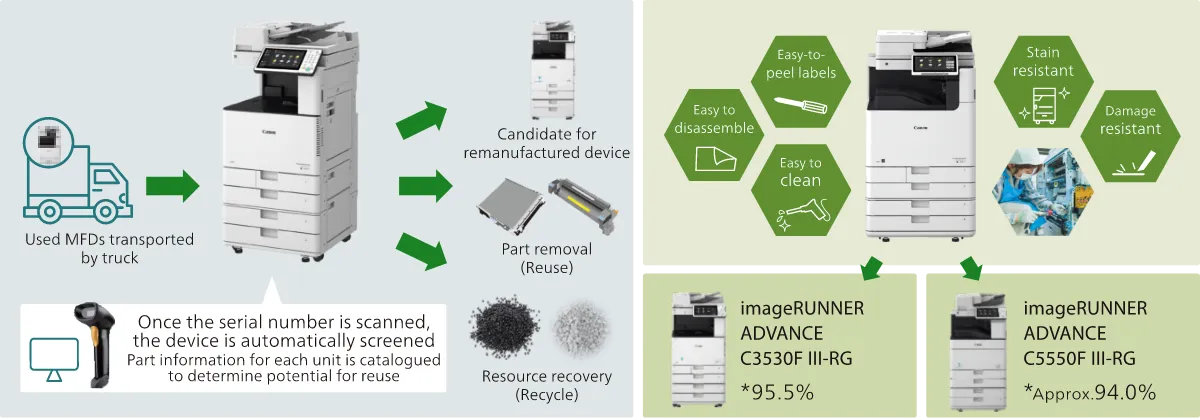

Since 1992, Canon has undertaken remanufacturing of used multifunction devices. This process involves a system that automatically determines which parts should be reused, based on operating data about the equipment, such as the number of years in use, its history of breakdowns, and the number of pages printed. Then, following strict reuse standards, we replace any parts that show wear or deterioration. The production line and inspection processes used are on a par with those for devices made only with new parts. When a remanufactured device is shipped, it is guaranteed to offer the same level of quality as a new product. We market remanufactured devices from the imageRUNNER ADVANCE series under the Refreshed series brand in Japan and under the ES series brand in Europe.

Remanufacturing Flowchart (Canon Ecology industry, in japan)

1. Collection

The used products that have been collected are gathered up and go through an initial check

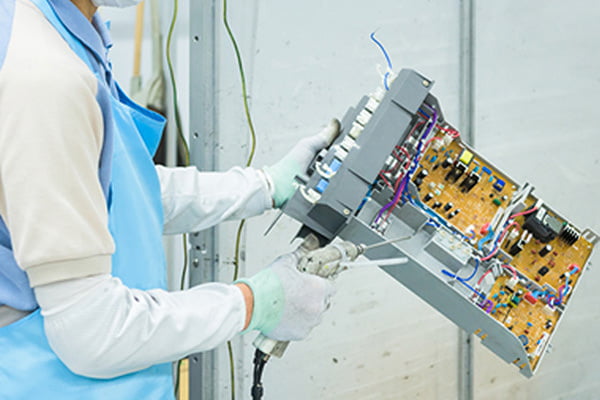

2. Disassembly

The exterior covers and parts are removed

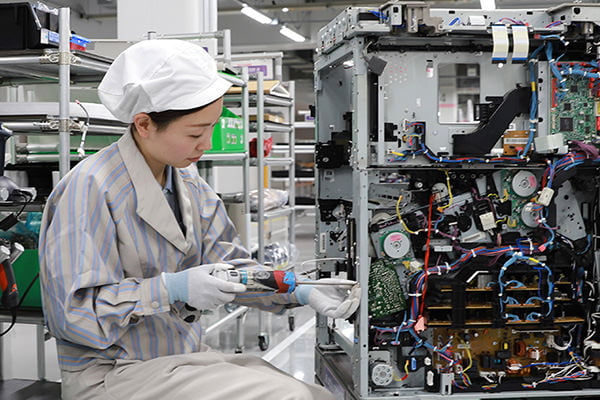

3. Cleaning

The body's frame and the parts that were disassembled are cleaned

4. Assembly process

The cleaned frames are assembled with new and reused parts, and then the exterior covers are attached.

5. Inspection

The same inspection as for new products are done to make sure that all the functions work appropriately.

6. Shipping and sales

The products are packaged just like a new product, and the sent to market.

Remanufacturing of Multifunction Devices

「imageRUNNER ADVANCE C3530FⅢ-RG」

In the Refreshed series, we have achieved a reused parts ratio of over 90% in all color multifunction devices. Especially in the imageRUNNER ADVANCE C3530F III-RG, we achieved an industry-leading reused parts ratio of 95.5% by removing the smallest imperfections with the use of sandblast polishing.* And to promote the recycling of resources even further, we use approximately 83% recycled plastic in all of the plastic used in the packaging materials. In addition, Canon is creating product platforms to standardize parts and designing products that are easy to reuse and recycle through disassembly and cleaning.

We received the METI Minister's Prize at the FY2024 3Rs (which stands for Reuse, Reduce, and Recycle) Promotion Merit Awards, hosted by the 3Rs Promotion Council, in recognition for achieving a high level of environmental performance (high reused parts ratio) and like-new high quality.

- * A technique for polishing resin surfaces by blasting with microparticles

Remanufactured MFDs with a high rate of part reuse

* https://www.3r-suishinkyogikai.jp/commend/commend/ (Japanese only)

Reuse of Parts

Canon collects parts from used products for maintenance purposes. Parts extracted from used products and collected parts undergo disassembly, washing, cleaning, and reassembly before being reintroduced to the market as components of remanufactured products or as maintenance parts.

Canon Giessen in Germany, Canon Virginia in the U.S., and Canon Eco Technology Park in Japan are engaged in the reuse of parts. The latter in particular is meeting maintenance demand after ceasing the production of machine casings by operating production lines for new and reused parts in parallel. By reusing some of the collected parts in the production of new parts, we can reduce the use of new resources.

Development and Use of Recycled Plastic with PCR* Rate of 70-100%

Canon Ecology Industry operates a closed-loop recycling system in which plastic parts extracted from collected machines are separated, washed and crushed to form pellets. The recycled plastic pellets are shipped to Canon production sites, creating a loop with a PCR rate of 70-100%. The cumulative volume of pellets shipped as of the end of 2024 was 51 tons.

- * PCR= post-consumer recycling (proportion of materials from returned post-use products that is recycled)