Resource Efficiency

Reduction of Waste

Initiatives to Reduce Waste at Operational Sites

Canon is working hard to reduce the amount of waste it generates. Efforts include increasing recycling through sorting and collection and minimizing initial waste generation. In particular, we have sought to determine which factors most significantly affect waste generation at production sites for each division and each production process. Canon Prachinburi (Thailand) is engaged in the recycling of plastic scraps generated during production, while Canon Dalian Business Machines is working on the filtration and recycling of grinding fluids. In addition, Fukushima Canon and the Toride Plant have introduced an automatic collection and aggregation system for waste data at the time of disposal, making it easier to allocate waste by workplace and facilitating efficient reduction activities.

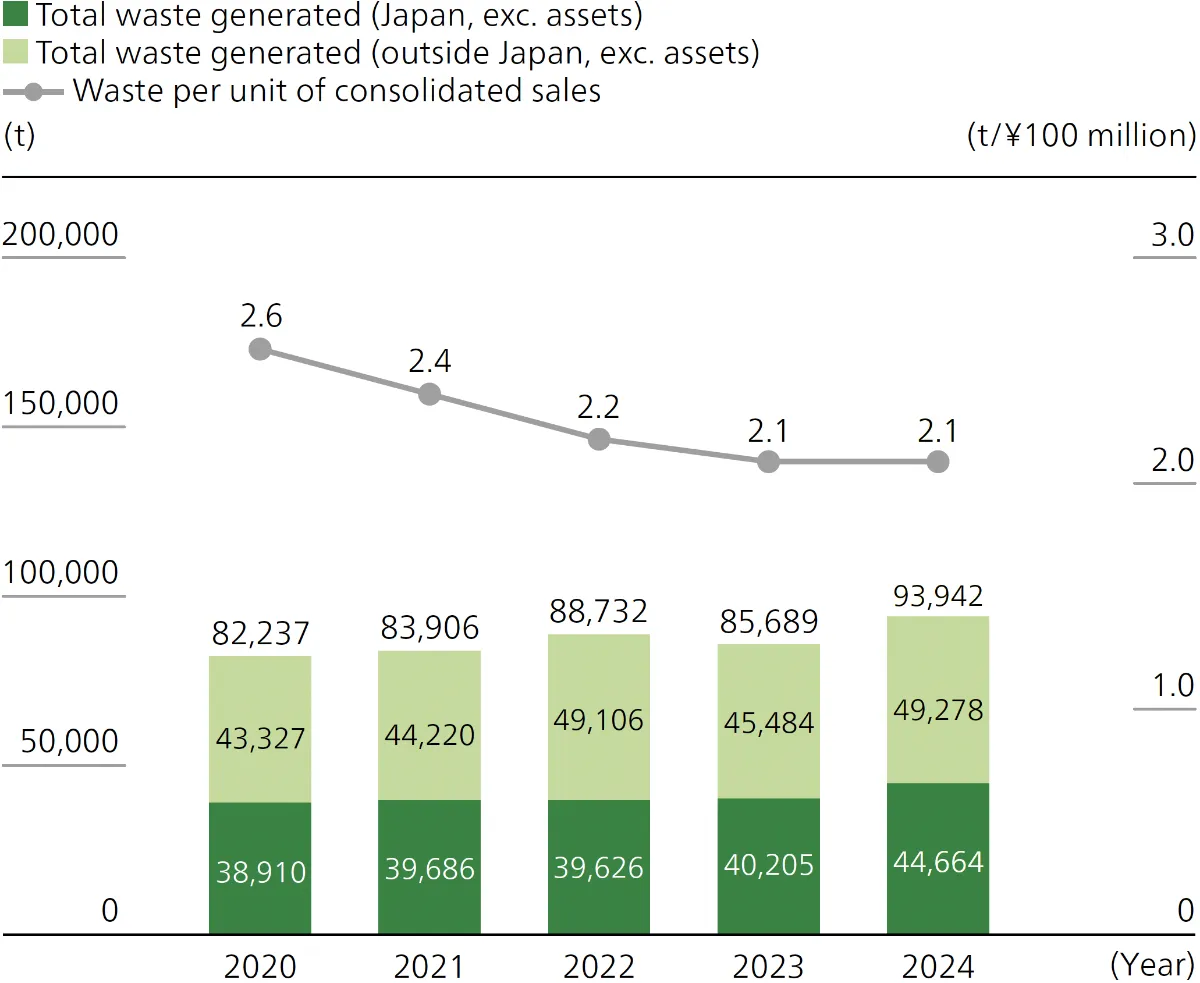

Total waste generated in 2024 was 93,942 tons, an increase of 9.6% compared to 2023.

- * Excludes disposal of products collected after use.

- * The scope of aggregation mainly includes companies that have acquired ISO 14001 consolidated certification.

Initiatives Related to In-house Waste Recycling and Outside Resource Recovery

Canon actively works to reduce the amount of waste originating from its operations and to reuse or recycle waste where possible, appropriately disposing of any waste that can be neither reused nor recycled in accordance with the law. Our various operational sites employ a range of in-house recycling schemes, including reprocessing waste plastic from injection molding as artificial wooden benches or recycling it for other items. Even in the case of waste that must be sent outside the company, we outsource the recycling of each resource to ensure that it does not enter landfills*. Rather, we contract with companies that reprocess waste into materials. In 2024, contracted companies processed 92,229 tons of waste from Canon back into materials.

- * Except for some general waste generated by business activities that is disposed of under government oversight.

Initiatives for Efficient Use of Resources: Use of Recycled Toner Pellets

In a joint project with an asphalt services firm Basic Construction Company, Canon Virginia Inc. has developed a new asphalt material containing an admixture of recycled toner pellets made from the waste toner in used cartridges. The polymer that is the main constituent of the recycled toner pellets improves the strength of the new material, which can reduce the use of asphalt binders, whose price has soared. The new asphalt material has been used on public roads in the US state of Virginia, realizing both effective use of resources and cost economies.

Action to Reduce Disposable Plastics

We are working to find alternatives for single-use plastics in our product packaging materials.

Initiatives for plastic-free packaging materials

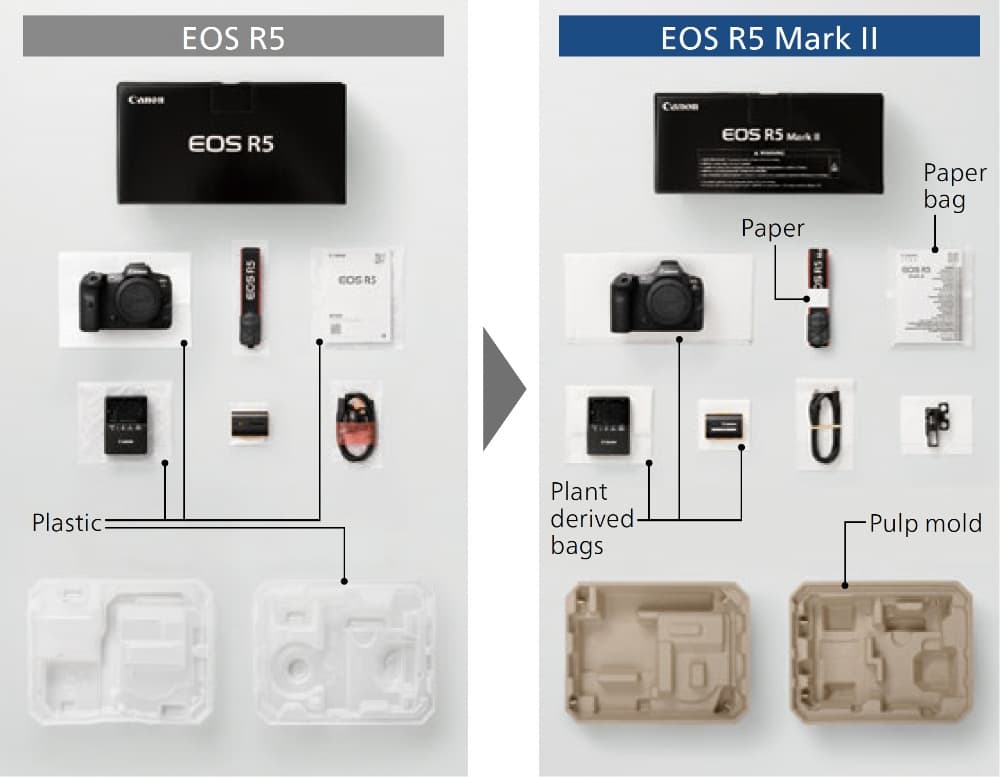

We aim to eliminate petroleum-based single-use plastics* in the packaging materials of newly designed products of the imaging group by 2030. Starting with the PowerShot V10 released in 2023, we have eliminated the use of plastic packaging in 24 models, including the EOS R5 Mark II, RF35mm F1.4 L VCM, and related accessories. (products announced in FY2024)

- * This refers to petroleum-derived plastics, and excludes the raw materials used for labels, coatings, and adhesives.

The PowerShot V10, for example, uses plant-derived non-woven fabrics and paper materials for the bags used to package the camera and its accessories. Selecting these materials cuts down on single-use plastics and reduce environmental impact.

Through such efforts, the PowerShot V10 received the Electric Equipment Packaging Award at the Japan Packaging Contest 2023, hosted by the Japan Packaging Institute, in recognition of its marked contributions to the rationalization and improvement of electrical equipment packaging.

Click here for details on the Japan Packaging Contest

The Japan Packaging Institute hosts the Japan Packaging Contest every year to encourage the development and widespread use of outstanding packaging and packaging technologies in Japan.

For the lens RF-S10-18mm F4.5-6.3 IS STM package, we are making efforts to use plant-based non-woven fabrics and paper materials for the first time in our lens products.

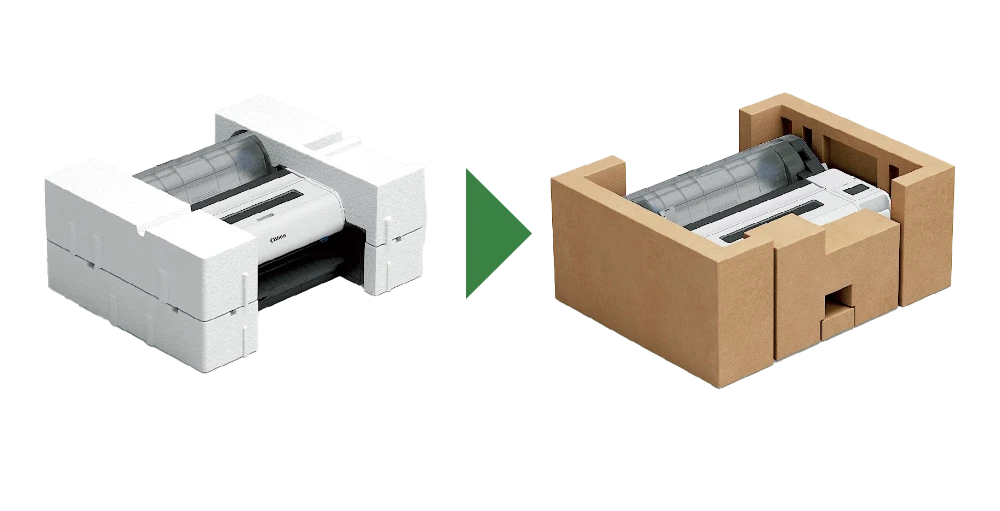

Among the Canon products launched in 2024, 15 inkjet printers utilize pulp molds. Our office MFD imageFORCE C7165* and the imagePROGRAF series of large-format inkjet printers both use corrugated board. Also, corrugated board is used in the packaging materials for some laser cartridges.

- * Not applicable to Asia (excluding Taiwan)

Pulp molds

Corrugated board

Corrugated board

The issue with corrugated board is their increased weight, as more material is usually needed to achieve the same functionality as expanded polystyrene. To reduce packaging volumes while maintaining functionality, we are adopting packaging designs based on the use of prefabricated corrugated board, which reduces the weight and helps to lower CO2 emissions in the transportation process.

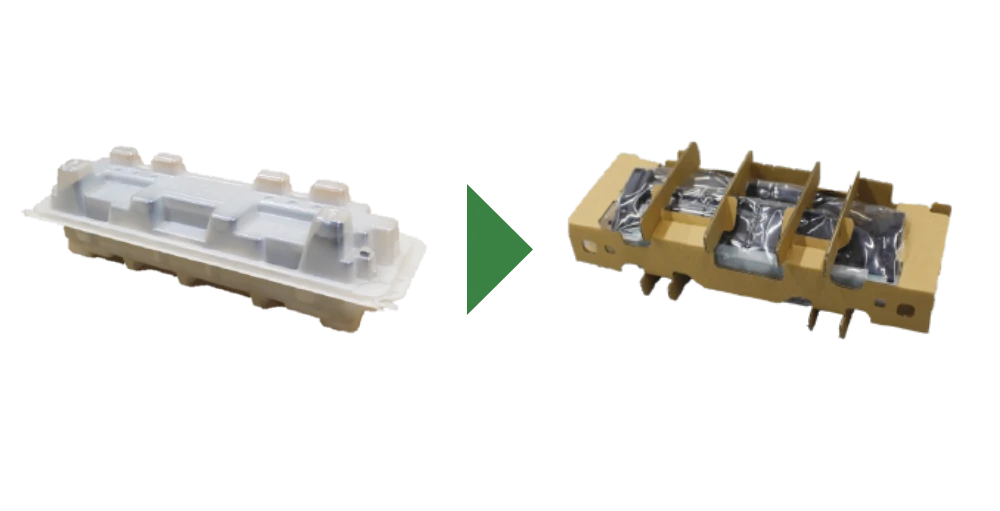

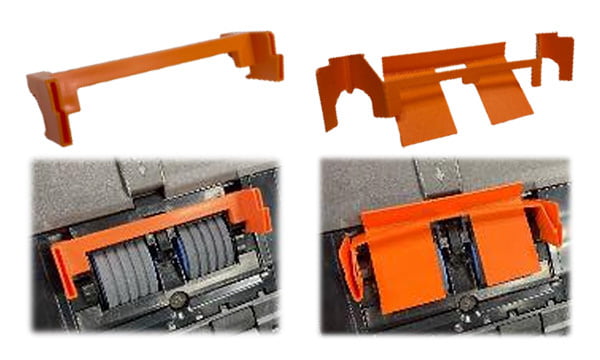

CANON ELECTRONICS has switched from the use of polystyrene foam to compostable and recyclable paper for the packaging materials for its R10, P-215II, and DR-M140II Document Scanners.

The company has also switched from the use of plastics to compostable and recyclable paper for the protective materials for its Document Scanner rollers. It has also stopped using polyethylene individual packaging bags for its Document Scanner power cords when they are supplied by vendors, and switched to the use of biomass plastic bags for packaging its AC adaptors.

(DR-C230,C240,M160II,M260,S130,S150,R40,RS40,R50,SF400)

- Example of packaging materials for power cords and AC adaptors

(DR-C230,C240,M160II, M1060II, M140II, M260,S130,S150,R30, R40,RS40,R50,SF400)

Additionally, Canon is a member of the Clean Ocean Material Alliance (CLOMA), a public-private sector alliance that seeks a solution to the problem of marine plastic pollution through accelerated innovation and collaboration among a wide range of interested parties across industry borders. In coordination with CLOMA, we are working on a range of initiatives, including reducing the use of plastics and developing recycle friendly products, technologies, and systems.

Use of Biomass and Recycled Plastics

The HS-1220TUB and TS-122TUB tabletop calculators and the LS-122TUB mini tabletop calculator use biomass plastic materials made from plant resources and recycled plastic made from plastic waste. These products have also obtained Japan's Eco Mark and Biomass Mark certifications, as well as complying with the Green Purchasing Act* stipulated by the Ministry of the Environment. In these ways, Canon is reducing environmental impact during manufacturing.

- * A Japanese law in effect since 2000 that promotes environmentally friendly product procurement, centered on the national government.

Canon Opto Malaysia, in cooperation with the Selangor State Department of Environment, held an event on World Environment Day at the National Botanical Garden Shah Alam to raise awareness of environmental issues. A total of 500 reusable bags were distributed to attendees to promote the reduction of single-use plastic usage.