Technology in ProductsTechnology Used in Office Multifunction Devices

Making Office Work Even More Convenient by Combining Multiple Devices in a Single Unit

Office multifunction devices (MFDs) handle all kinds of office tasks, such as copying, printing, scanning, and faxing, with a single device. Not only are they capable of high image quality, high performance printing, but as devices that play central roles in office document networks, they also offer improved security and cloud functionality that helps them rapidly adapt to workstyle changes.

April 14, 2022

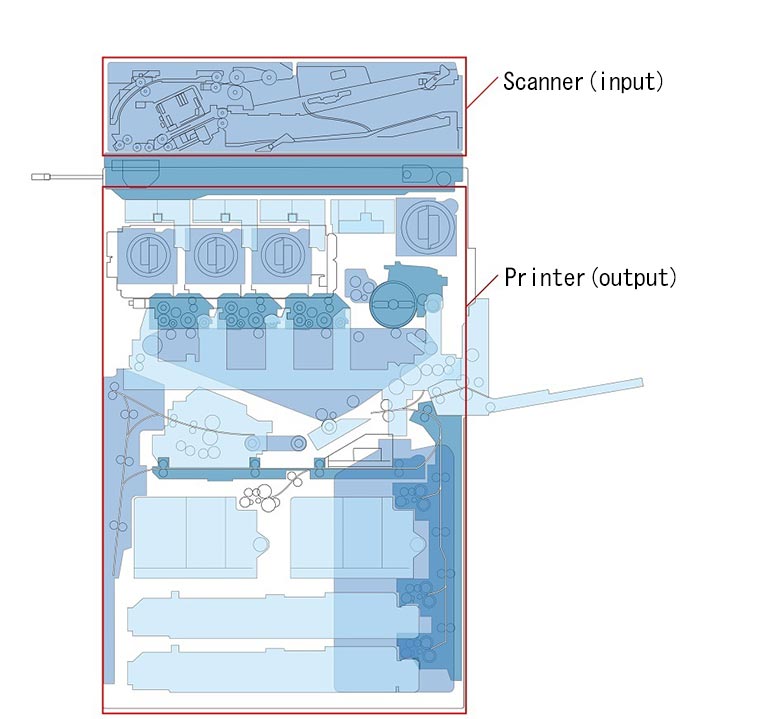

How MFDs work

MFD hardware can be broadly divided into two main types: scanners (input) and printers (output). Scanners directly read documents into the MFD and convert them into digital signals. Printers use data received from computers or scanned into the device to create images on cylindrical photosensitive drums using laser light. Fine powdered plastic particles called toner, in four different colors (cyan, magenta, yellow and black) adhere to the drum and are transferred to the paper using static electricity in a printing process called "electrophotography."

Read More

Technologies used in MFDs

The electrophotography process

Compact long-life drum cartridge system

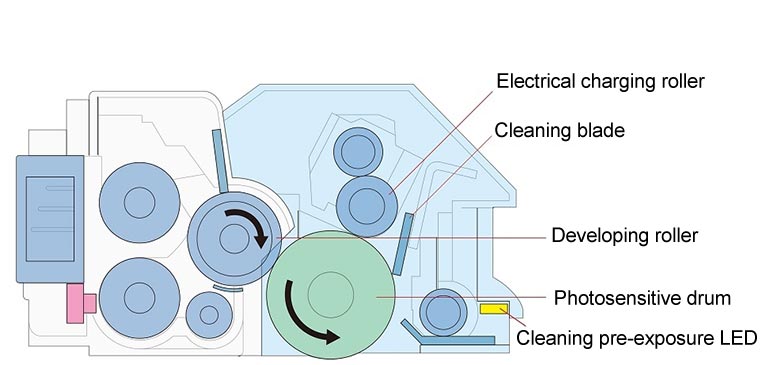

MFDs that print using the electrophotography process have required regular maintenance due to the wear suffered by the photosensitive drum. Canon has developed a compact long-life drum cartridge to reduce the frequency with which maintenance is needed, thereby saving resources.

The E (Excellent) Drum incorporated in this system is a photosensitive drum boasting high durability and high stability thanks to the addition of a layer of wear-resistant coating developed in-house by Canon. The Compact Long-Life Drum Cartridge System utilizes the long-life properties of the E Drum, while adding three new mechanisms to ensure even greater compactness at a lower cost. The electrical charging roller cleaning mechanism reduces contamination and achieves a significantly longer service life through the addition of a cleaning component to the electrical charging roller. The cleaner pre-exposure mechanism contributes to providing a more compact size at a lower cost by using an LED as the light source for removing residual charge from the photosensitive drum after developing. Furthermore, the toner removal cleaner mechanism reduces photosensitive drum abrasion by applying the optimal amount of force to the cleaning blade.

Cross-section of the drum cartridge

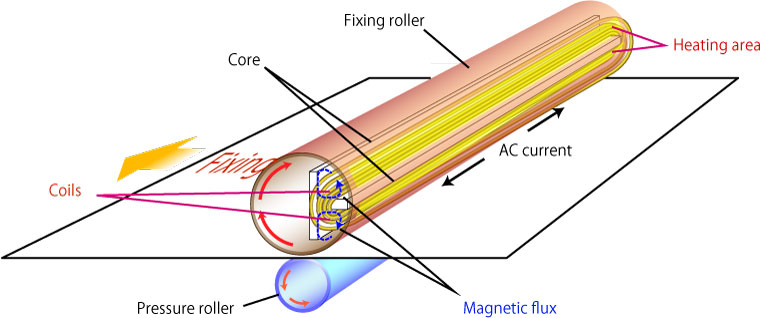

Induction heating fixing technology

Previously, high-speed MFDs had to use high pressures and temperatures to rapidly melt toner and fix it to paper, a process that required long warm-up times. This meant that MFDs required large fixing rollers that were strong and had high thermal tolerances, and it took a long time for the rollers to reach the temperature needed for toner fixing.

That’s why Canon developed a highly efficient induction heating (IH) roller method that combines induction heating with a thin fixing roller. A high-frequency electric current is passed through a coil, and the induction heating produced heats up the entire roller. This method offers exceptional heating efficiency and makes possible sufficient toner melting and fixing with a thin fixing roller.

IH (Induction Heating) Fixing

Thanks to the IH method, Canon has managed to reduce the warm-up time of its MFDs to 1/6 of previous levels. In addition, Canon’s TEC* value, an energy-saving evaluation standard used to determine compliance with the international ENERGY STAR program, has been reduced to 1/3 of previous levels.

* Typical Electricity Consumption

The amount of power consumed during one week of typical use. This value is used by the international ENERGY STAR program.

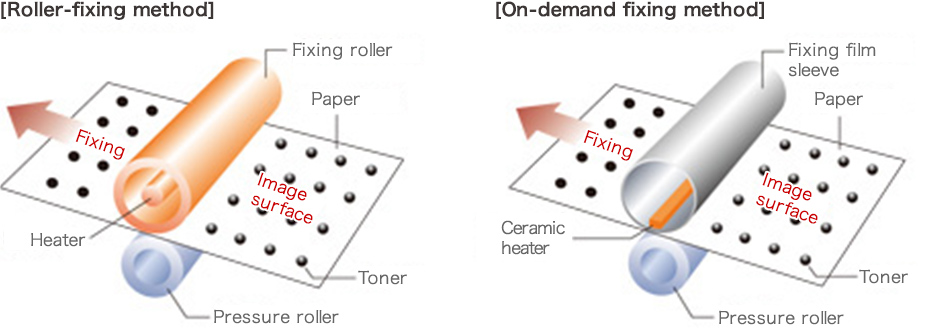

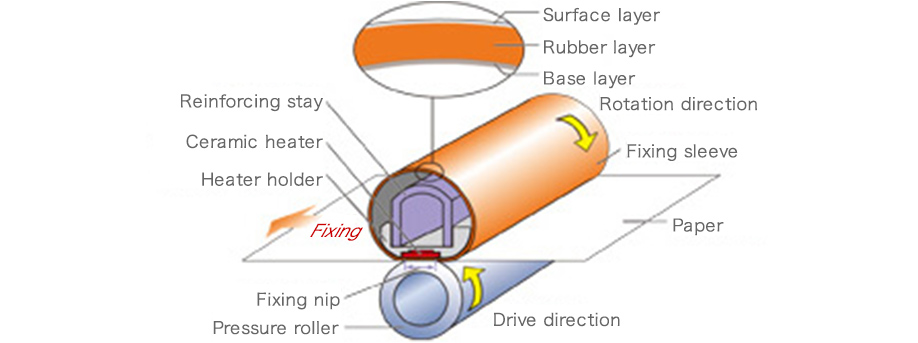

On-demand fixing technology

In the past, medium and low-speed MFDs have used the conventional roller fixing method to fix toner. An internal heater was used to heat the fixing roller, so it was necessary to constantly supply power to the heater while the printer was in standby so that the roller stayed warm and ready to begin printing on short notice. Canon's unique on-demand fixing technology employs a fixing film with high thermal conductivity and low thermal capacity together with a ceramic heater in order to apply heat directly to the fixing film. The heater operates only when the fixing film rotates, and heat is transferred to the toner via the film, thereby fixing the images to the paper. This eliminates the need for heating time and maintaining roller heat, so the MFD can start printing quickly while also saving power. The fixing film is made up of three layers: a base layer, an elastic layer and a surface layer. The base layer is made with material that has high thermal conductivity and low thermal capacity. It can be quickly heated and used to efficiently transfer heat to the toner. In addition, a special kind of rubber is used for the elastic layer between the base layer and surface layer. The elastic layer adheres to the uneven surface of paper in order to uniformly apply heat and pressure. The surface layer is made of a fluoropolymer to improve its release properties and prevent toner from bonding to it.

Differences Between the Roller Fixing Method and On-Demand Fixing Method

The ceramic heater consists of a ceramic substrate covered by a resistive element and protective layer. Heat is generated by applying an electrical current to this resistive element. To efficiently transfer the heat generated by the resistive element to the fixing film, the ceramic substrate and protective layer are designed as thin layers, while the heater holder, which supports the ceramic heater, employs a heat-resistant resin that acts as a thermal insulator.

CV toner

Canon's toner, which is used to perform printing, was also developed from the ground up. Canon has developed, and utilizes, CV toner for MFDs that is designed to achieve optimized melting properties while maintaining highly precise pigment dispersion. This ensures consistent colors even during high-volume printing and makes possible excellent color reproduction comparable to that of offset printing. The toner also boasts superior transfer performance and durability to reduce color spotting and other types of image roughness when printing on various types of media. CV toner helps maintain high-resolution, vivid image quality for a longer period of time.

Network integration technologies

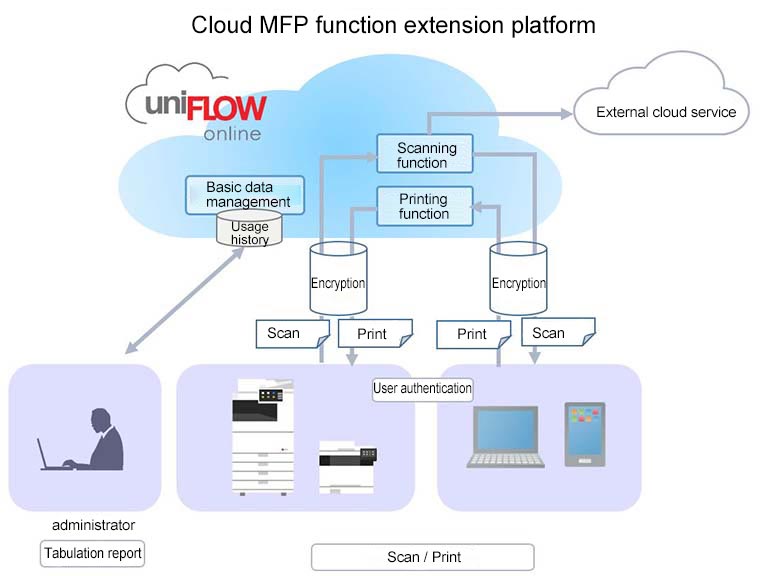

Cloud platform technologies

In recent years, cloud services have been used for in-house and external file management, business systems such as labor, personnel, accounting, and sales systems, and industry-specific support software for such fields as education, healthcare, finance and legal. Canon has developed its own cloud platform whose functions enable its MFDs to securely connect to and communicate with external cloud services. This platform can be used to integrate and manage device information collected from multiple MFDs in the cloud. The platform is composed of many different technologies. These include data processing technologies that send data directly to cloud services; connection and communications technologies that share data between MFDs and the cloud; encryption technology that protects data on communication channels; multi-tenant technology that prevents data leakage in situations in which multiple companies jointly utilize one cloud environment; and authentication technology that limits who can use a particular MFD.

The uniFLOW Online platform provides expanded functionality, integrating MFDs with the cloud to enable the use of an even wider range of services. These include functions that contribute to greater operation efficiency, such as individual user authentication, usage history management and report creation, the transmission of scanned data from an MFD to an external storage service, printing on other cloud-connected MFDs, and printing from mobile devices.

Improved integration between MFDs and with computers

Canon's imageRUNNER ADVANCE MFDs are a new type of MFD developed ahead of the competition and based on a user-centric concept. They were designed not only to achieve ease of use, but also to increase operational efficiency by networking with office computers or other imageRUNNER ADVANCE MFDs.

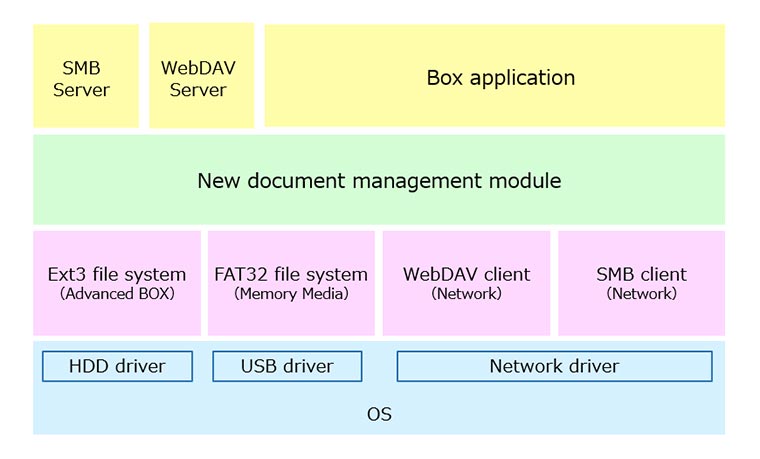

One of the core functions supporting this system networking is the Advanced Box function, which utilizes the device’s built-in storage construct to offer MFD box functions*1 and simple file server functions. This advancement was achieved by creating a new document management module within the OS file system layer. The new document management module incorporates embedded application modules for controlling the operation of each of the Advanced Box, network (SMB, WebDAV), and memory media repositories*2, allowing users to use the Advanced Box without having to worry about differences between repositories.

*1 Box functions

Functions used to temporarily store data in an internal storage device and to retrieve and use it when needed.

*2 Repository

Repositories are databases that contain such information as system design information and program data.

Advanced Box / Advanced space -Related Software Structure

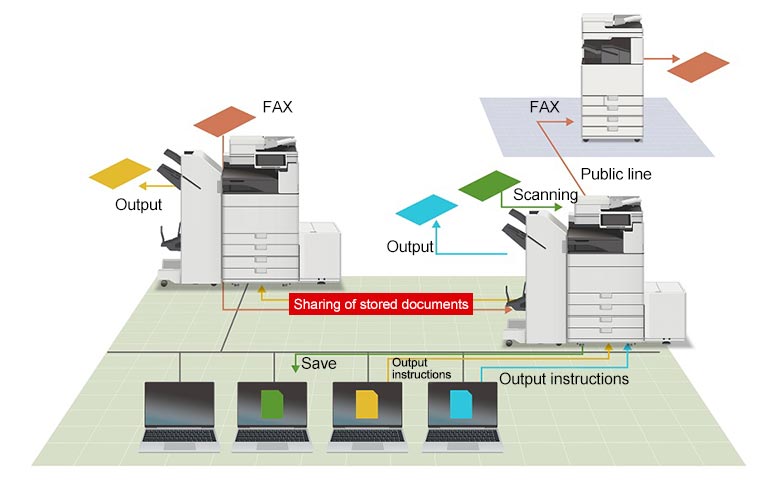

The Advanced Box function offers compatibility with multiple standard protocols, such as SMB and WebDAV, for enhanced adaptability with various network environments in the era of cloud computing. Providing the MFDs with both server and client functionality makes it possible to link multiple imageRUNNER ADVANCE machines together, as well as with computers.

The Advanced Box function enables access to data on MFDs in the same way as accessing a file server, with no need to install special applications on a computer. For example, a printed PowerPoint presentation can be scanned and saved in Advanced Box in both PowerPoint and PDF file formats, enabling access and use at any time from a linked computer without having to prepare a separate file server. Even imageRUNNER ADVANCE machines not equipped with storage devices can connect to other imageRUNNER ADVANCE systems linked via an intranet and used as if they had their own Advanced Box.

Additionally, the address book sharing function allows any imageRUNNER ADVANCE system to look up and use registered address information simply by registering addresses used by multiple parties within an office on a single imageRUNNER ADVANCE machine connected via an intranet. The address book framework was built based on the WebService platform offered by Canon's MFDs, ensuring its scalability*3 and enabling multiple MFDs on a network to share address books.

The various functions offered by imageRUNNER ADVANCE improve connectivity between multiple MFDs and other MFDs and computers, leading to significantly improved office workflows.

*3 Scalability

Scalability is the potential to expand a computer system. It refers to the ability to flexibly improve performance and functionality, regardless of the scale of the system.

Security technologies

Information security technology

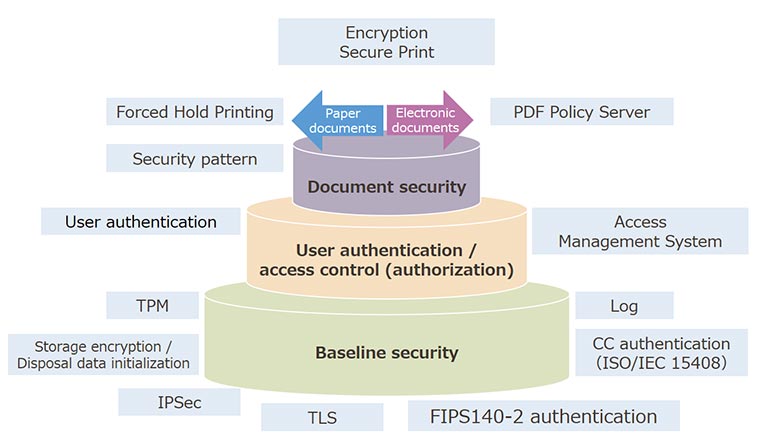

In offices, MFDs serve as hubs for the input and output of documents. As companies become more dependent on networks and documents grow increasingly important, there is a greater need for advanced security on par with computers. Canon MFDs employ a number of network and information security functions, and the company continually strives to further improve these features so that customers can use their MFDs with peace of mind.

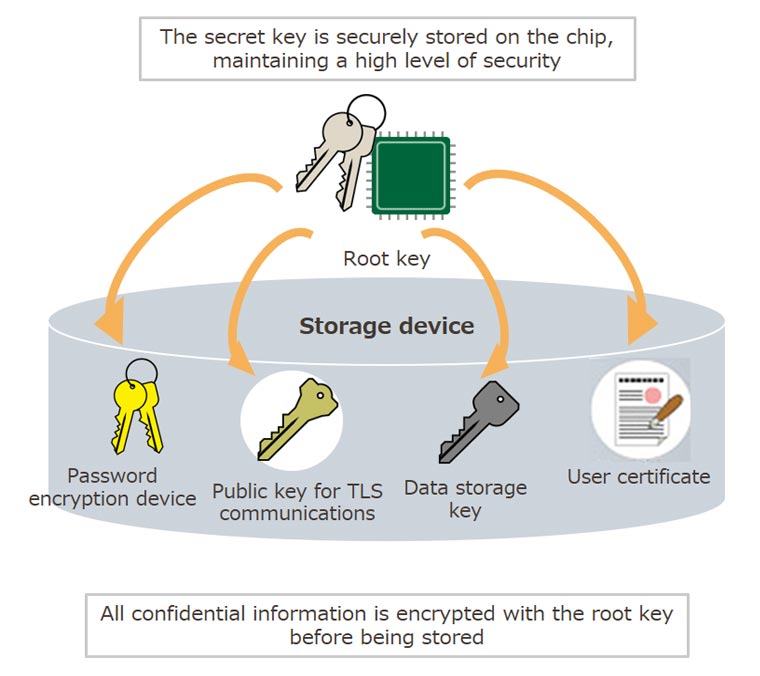

Technologies for preventing the leakage of confidential information

MFDs, like computers and servers, store a great deal of confidential information within their internal storage, including passwords and encryption keys. The Trusted Platform Module (TPM) chip* plays an important role in protecting the confidential information contained in MFDs from physical analysis and unauthorized network access. All confidential information is encrypted using the root key on the TPM chip before being stored. The root key never leaves the chip, ensuring the protection of confidential information within the MFD.

* Trusted Platform Module (TPM) chip

Trusted platform module chips are physical security chips contained in computers and MFDs. The chips can perform encryption, decryption, and digital-signature generation and verification.

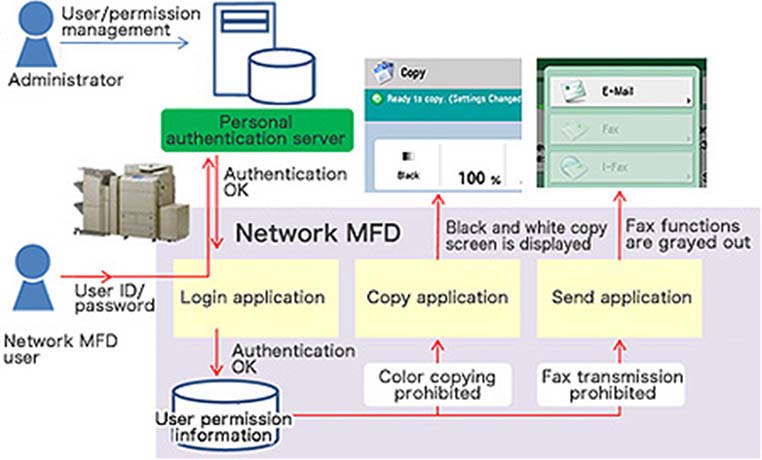

Technologies for preventing unauthorized use through function restrictions

Access Management System technology prevents unauthorized device usage by restricting which functions can be used on a per-user basis. IT administrators can configure in advance which functions can be used by which users, so that users will only see the screens for which they have been granted usage permission. Access Control Tokens (ACTs)*1 are used when sending print orders from computers to MFDs, making it possible to implement print restrictions and prevent print data tampering and replaying.

Canon's MEAP application platform optimizes MFDs for office operations. Applications that support MEAP can be used to easily work with existing company security systems including employee management systems, Smart card authentication and Active Directory*2.

*1 Access Control Token (ACT)

Access restriction information issued by a computer to control, on an individual user basis, whether or not printing can be performed.

*2 Active Directory

A directory service developed by Microsoft used to manage computer user information and computer resources, such as software, hardware, and CPUs. It is often used in large-scale computer networks.

Technologies for preventing tampering

Preventing firmware tampering

Encryption and digital signature authentication are used when updating MFD firmware or installing MEAP applications* to prevent the installation of unauthorized programs.

* MEAP application

An application that runs on Canon MFDs

Tampering detection during MFD operation

This function offers even greater security during device operation by checking that firmware and MEAP applications have not been tampered with by checking them against a whitelist (a list of trusted firmware and applications).This prevents unauthorized, unknown programs from being executed.

Tampering detection upon MFD startup

This function enhances security during device operation by checking that none of the programs used by the system, such as the MFD's firmware or MEAP applications, have been tampered with, confirming their safety. If tampering is detected, the MFD will not start up, preventing the unauthorized program from running and causing damage. This approach is also effective in preventing unknown attacks, thus offering even more robust security.

Controller technologies

Canon's proprietary MEAP platform

"MEAP" is an OS-independent Java application platform incorporated into Canon MFDs. MEAP applications for such tasks as system authentication and output management, office document use and operation workflow efficiency improvement, are installed based on users' needs, thereby optimizing MFDs for individual working environments. MEAP software mainly comprises three components: the basic MEAP platform, which provides the application execution environment; the MEAP system service, which provides MFD system-related functionality; and MEAP applications, which use the platform and system service.

"MEAP Web" provides a web browser built into the MFD and Service Provider, a MEAP service that provides API to web applications, for controlling the MFD. This makes it possible to seamlessly operate MFDs from web applications. MEAP Web dramatically improves the integration of customers' web operation systems and MFDs, thus contributing to greater document-related operation efficiency.

* MEAP: Multifunctional Embedded Application Platform

Controller architecture

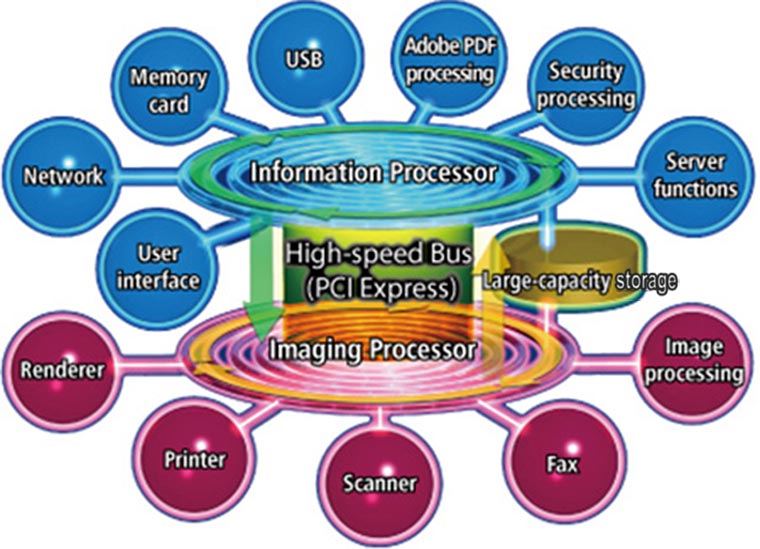

Office MFDs that carry out concurrent processing such as printing and scanning handle enormous volumes of data. Because of this, the cores of these products need to efficiently process multiple functions. Canon develops dedicated processors tailored to individual products.

To increase overall system performance and the ability to provide solutions, the "Advanced iR Controller" comprises an image processing controller unit equipped with an image processor, along with an information processing controller unit equipped with an information processor. Not only is processing speed maximized by connecting these two controllers using a high-speed PCI Express bus, but each of the controllers is also optimized, thereby contributing to the evolution of document workflows.

The image processor incorporates advanced image processing technologies in addition to providing faster printing and scanning, which are the basic functions of an MFD. The information processor boasts excellent compatibility with network and Internet environments and provides numerous new functions by integrating security functions with external systems.

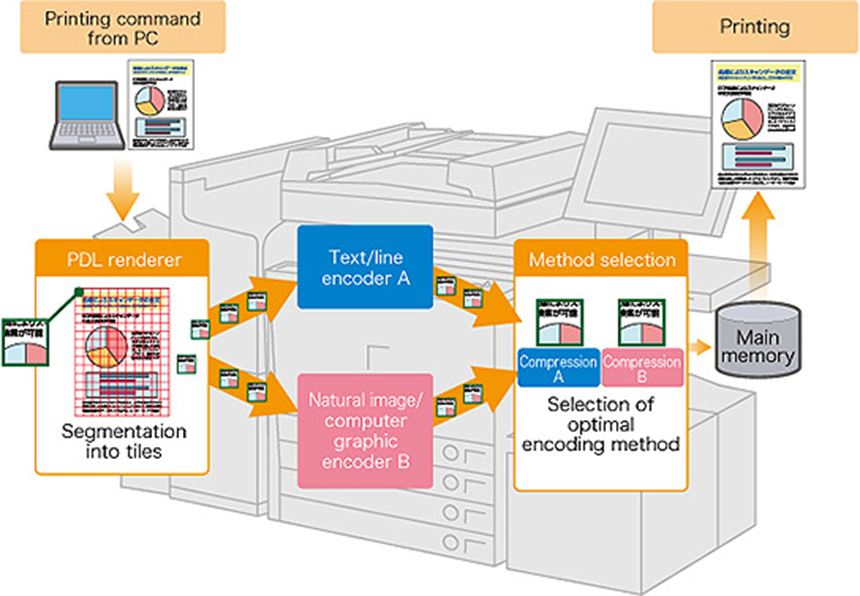

VL compression technology

Printing A4 sized image data at 600dpi in full color requires 100MB of image storage space. To process this much information quickly, compression technology must be fast and highly efficient. Visually lossless (VL) compression technology is a unique Canon image compression technology that appropriately balances the image quality and compression ratio of PDL* data. When a command is received from a computer to print PDL data, the printer first divides the PDL data up into many small tiles. The segmented image data is then sent in random order. What makes this technology notable is that during this process, it automatically divides the data into two types.

People seldom notice compression degradation in natural images and complex computer graphics, even if they are highly compressed. This means that even if high compression coding is performed on images such as these, they will be recognized as being suitably high quality images. High compression rates are therefore used on this type of image data.

On the other hand, compression degradation is very noticeable in text and in images with many lines, so a compression method which produces little degradation must be used. Automatically applying different compression methods depending on the type of image data makes possible fast, highly efficient compression.

100MB images compressed to approximately 2.5MB (roughly 1/40th of their original sizes) using VL compression and JPEG compression. The images compressed using VL compression have a noticeably higher image quality than those compressed using JPEG compression.

* PDL

Page Description Language. PDLs are languages used to provide printers with descriptions of printouts when printing documents or images created on a computer. Typical PDLs include Canon's UFR II and Adobe System's PostScript.

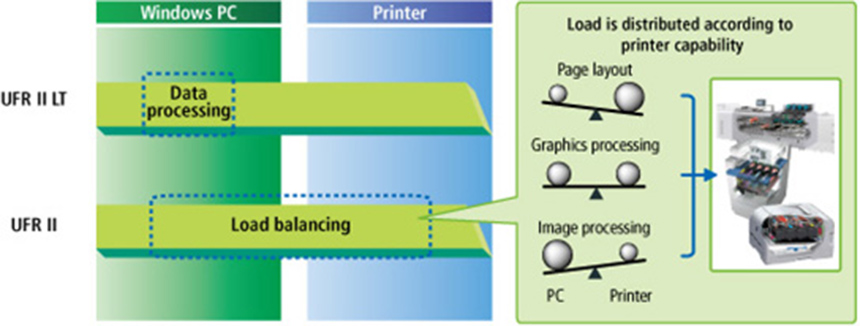

Printing system technologies

Canon laser printers and MFDs incorporate UFR II, a PDL developed by Canon for printers. UFR II efficiently distributes the processing of all print data components between the computer and the printer, thus shortening total print processing time. The level of performance is largely the same regardless of the type of data or the printer environment, enabling consistent, high-speed printing.

UFR II LT uses computer CPUs, which continue to become even more powerful, to perform optimized print processing at little cost. Rendering work which was previously handled by the printer can now be performed entirely by the computer. Canon's unique technologies are used to apply high compression to data so that even large amounts of data can be printed smoothly, without the need for printer memory expansion.

High-speed RIP

In ordinary printers, the raster image processer (RIP) is implemented in software (software RIP). However, in the case of color printers, which handle large volumes of data, it is often impossible to achieve high-speed data processing using software RIP. Instead, the data must be processed with a hardware RIP. Canon has developed a core high-speed RIP technology that can be used for both software RIP or hardware RIP, with the aim of further increasing printer speeds and resolutions. This technology is being used in Canon's MFDs. Canon is furthering the optimization and parallelization of internal processing in order to accommodate higher speeds, while also developing technologies to enable fast processing of high-resolution data by compressing internal data.

Document processing technology

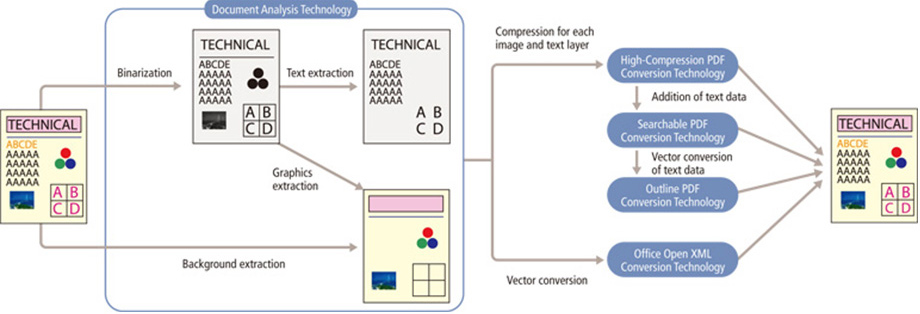

Canon MFDs do more than just make copies of scanned data. Built-in document processing technology enables the creation of reusable electronic documents by analyzing and processing scanned documents.

Document analysis technology is used to analyze the layout of a scanned document to extract objects such as text, diagrams, photographs, and graphics. They are then separated into their respective areas and document analysis is performed to generate basic attribute, position, and size data. Character recognition, vector conversion*, image processing and compression are then performed on the basic data to create high-quality documents.

* Vector conversion

Vector conversion involves rendering into a graphic expression format (vector data) that saves shape information independent of resolution. This enables smooth contours to be maintained even when an image is enlarged.

High-compression PDF conversion technology: high resolution with lower data volume

After text and image data are extracted using document analysis technology, they are separated into multiple layers. Each layer is then optimally compressed with high-compression PDF* conversion technology. This provides for a high-compression ratio while maintaining high resolution. Using conventional compression methods, an A4-size color image scanned at 150 dpi can be compressed to a file size of about 2 MB. With this technology, the same image scanned at a resolution equivalent to 300 dpi can be reduced to roughly one tenth of that size (200KB). Canon is the first company in the world to incorporate this technology into MFDs, and in doing so has dramatically improved performance when handling color document image data, which entails particularly high volumes of data, over networks.

* PDF: Portable Document Format

A document exchange format developed by Adobe Systems Inc. Widely used for sharing documents and displaying documents on the Internet.

Searchable PDF conversion technology: making it possible to search for text in image PDFs

Searchable PDF conversion technology enables text search within PDF documents by overlaying text, identified and extracted as data using document analysis technology, on the original image as a text layer. The technology achieves a fast processing speed of 20 pages per minute for A4-size documents, with a high accuracy rate of 97.75% (based on in-house Japanese-language evaluation samples). In addition to Japanese, this technology supports English as well as various European and Asian languages.

Outline PDF conversion technology: high-resolution text display

Outline PDF conversion technology represents the evolution of high-compression PDF conversion technology. Conventional technologies composed PDFs using text data and background data extracted from scanned images, but Canon's outline PDF converts text data into vector data and then compresses, producing high-resolution text regardless of the resolution of the output device.

Text and graphics data converted with outline PDF can also be reused in Adobe Illustrator, greatly expanding the range of reusability for scanned documents.

Promoting the reuse of paper documents with Microsoft Office file conversion technology

When scanning paper documents, Canon technology can convert characters into text data and save it in Word file format for editing. It can also convert text and diagram data into vector data, and save the documents in PowerPoint format while retaining images, backgrounds and layouts. This makes it easier to edit text and diagrams compared with conventional PDF conversion, substantially reducing the work required for data input and editing even when the original is a paper document.

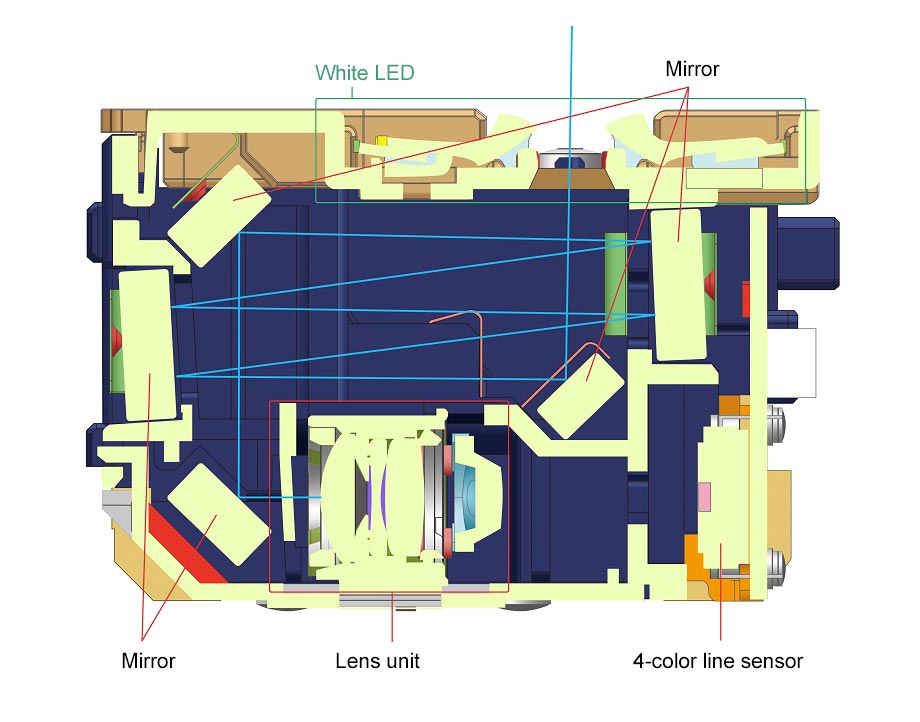

Single pass two-sided scanning technology

Normally, when scanning both sides of a document, it is necessary to flip the document over using a feeder* and scan each side separately. Canon has organized the elements of the optical system, which were previously arranged separately, into a single unit, making it possible to place scanner units on both the feeder side and the platen glass side. This enables simultaneous scanning of both sides of a document in a single pass, resulting in significantly faster scanning. Furthermore, this reduces the risk of damage to documents caused by paper jams, etc., during the scanning process and also eliminates the operating noise generated when flipping documents.

This scanner unit utilizes a compact high-performance 4-color line sensor, white LEDs and an aspherical lens unique to Canon. The achieves high-speed scanning thanks to a specially designed 4-color line sensor has a faster data transfer rate than conventional sensors. By using a white LED light source, power consumption has been reduced to roughly one quarter of the level when using a xenon lamp. Furthermore, using a lens unit with aspherical lenses provides a greater depth of field than in the past, making it possible to create a sense of depth when scanning an item with an uneven surface. The scanner unit has been made more compact, which helps reduce the space occupied by the MFD.

* Feeder

A mechanism for automatically transporting the document to the scanning area.