Technology in ProductsLarge-Format Inkjet Printers

Creating Large Prints with

Both High Productivity and Excellent Image Quality

Large-format inkjet printers are used not only for applications such as graphic art, photographs, posters, and CAD, but also indoor and outdoor advertising, such as signage and display advertisement printing, and industrial printing, such as wallpaper and decorative flooring printing. Each of these applications calls for different ink properties, so achieving both high productivity and excellent image quality differentiates Canon's large-format inkjet printers from its commercial printing competitors.

March 17, 2022

How Large-Format Inkjet Printers Work

Like consumer use inkjet printers, large-format inkjet printers perform high-speed printing of image data sent from computers and other devices. Extremely fine droplets of ink are dispenses at ultra-high speeds from the print head onto the paper.

Because high-definition images are printed at high speeds on large sheets of paper, these printers require hard disk drives capable of storing large amounts of image data, image processors able to process data at high speeds, precise print heads, and high-capacity ink tanks.

Read More

The Technologies Used in Large-Format Inkjet Printers

Canon offers a wide lineup of large-format inkjet printers to meet the needs of various markets.

Its imagePROGRAF PRO series for the graphic art market comprises 12-color and 8-color models.

For the CAD/poster market, the TX series, TM series and TA series provide improved productivity and security. Canon also offers models for indoor and outdoor advertisement printing and models that support diverse media including wallpaper and decorative flooring.

LUCIA PRO Ink, Expressing an Even Richer Color Gamut

LUCIA PRO ink is used in the imagePROGRAF PRO series of printers for graphic art applications.

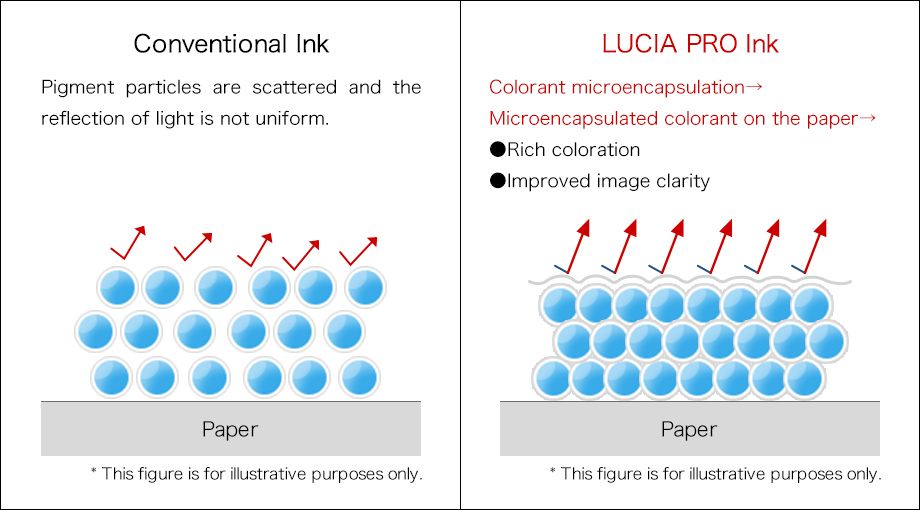

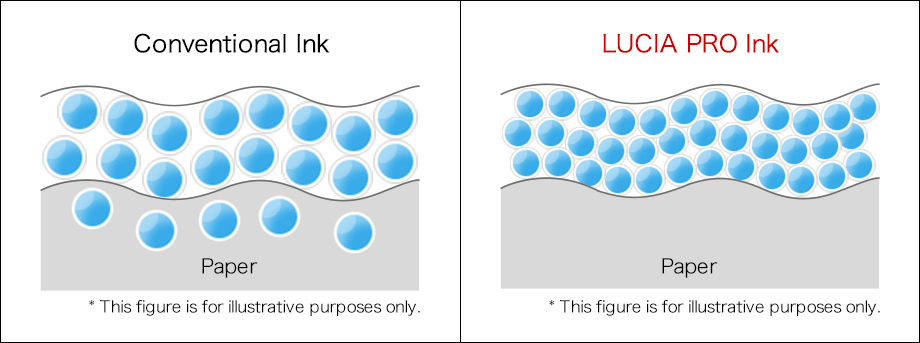

Canon uses microencapsulated* colorants to place ink on paper more precisely and densely, thus expanding the color gamut. The ink produces flatter, smoother printing surfaces on glossy and semi-glossy paper, reducing the scattering of light by the printed surface. This improves both glossiness and image clarity, resulting in higher quality prints.

* Microencapsulation: Technology used to cover the surfaces of colorant particles with a polymer

When printing on matte paper or art paper, the pigment remains in place on the surface of the paper, producing bright and vivid prints.

Chroma Optimizer Enables High-quality Printing on Glossy Paper

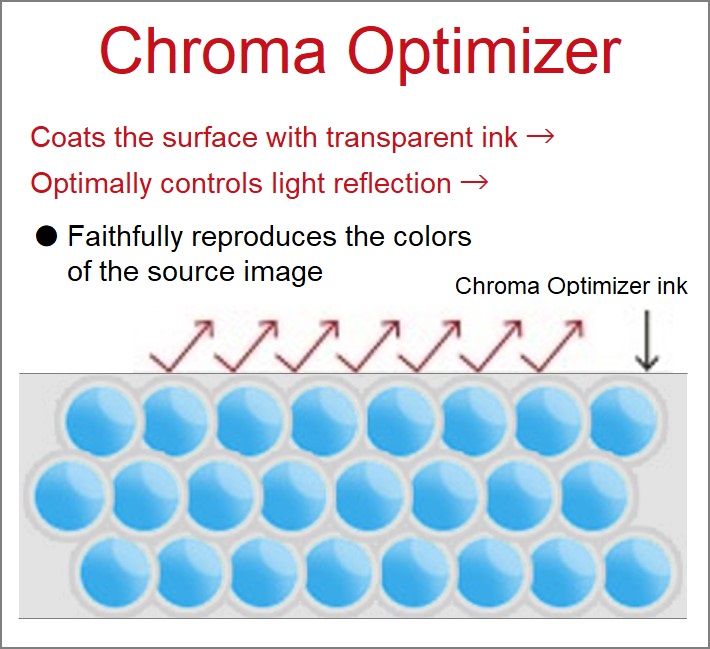

The 12-color models in the imagePROGRAF PRO series employ Chroma Optimizer, a transparent ink developed by Canon. Chroma Optimizer produces even higher image quality when printing on glossy paper or semi-gloss paper.

When someone looks at a print, the reflection of the ambient light will affect the color they see. Chroma Optimizer manages the reflection of light to ensure that the print faithfully reproduces the original work by keeping the vivid colors vivid and the pale colors pale, while also making the dark areas even darker and ensuring that blacks actually looks black, without blurring.

LUCIA TD Ink, Producing Vivid Colors Even on Plain Paper

The imagePROGRAF TX, TM and TA series printers for CAD and poster applications employ LUCIA TD ink.

When printing CAD drawings on plain inkjet paper with conventional 5-color dye and pigment ink models, lines and text can be reproduced in high quality. With conventional printers, however, it was not possible to achieve high quality when printing on plain paper not designed for inkjet use.

This is why Canon developed LUCIA TD 5-color full pigment ink, which uses a new type of matte black ink with high surface tension. This ink reduces the spread of wet ink droplets when they are placed on the paper making it easier for the colorants to stay near the surface of the paper. This helps achieve crisp lines and high-quality text with high density and little bleeding, even on uncoated paper—which does not have an ink-receiving layer—and is generally not suitable for inkjet printing.

What’s more, LUCIA TD employs new pigment inks for every color that realize superior water resistance. This means inks are unlikely to run when wet, so drawings can be easily carried and checked even when working outdoors.

High-definition reproduction of CAD images

Sharp Reproduction Even on Uncoated Paper |

|

|---|---|

Conventional ink |

LUCIA TD Ink |

|

Optimized surface tension |

|

|

|

|

When printing posters, although vivid colors can be achieved on coated inkjet paper or glossy paper, it is generally not possible to achieve satisfactory quality when using inkjet plain paper.

LUCIA TD ink uses an improved dispersant to enhance the reactivity between the pigment and the components of the paper. The pigment is therefore likely to adhere close to the surface of the paper, producing bright, vivid colors.

With LUCIA TD ink, exceptionally vivid posters can be produced even when using plain inkjet paper. This can help reduce costs by enabling users to internally handle printing that is typically outsourced, including posters, POP advertising and internal notices.

In addition, because all LUCIA TD ink colors use full pigment ink, they offer superior light fastness and are not likely to fade.

High-quality poster printing

Vivid posters printed using inexpensive inkjet plain paper |

|

|---|---|

|

Conventional inkLUCIA TD By increasing the reactivity between the pigment and components included in the paper, more pigment accumulates near the surface of the paper, which results in more vivid colors than conventional pigment ink. |

Automatic Roll Paper Setup

One of the distinguishing features of Canon's large-format printers is their high degree of usability.

With the imagePROGRAF PRO series for graphic art applications and the imagePROGRAF TX series for high-end CAD and poster printing, new rolls of paper can be set up automatically by simply placing them in the printer paper feed area.

Once a roll is loaded, the paper is automatically fed in, and then the built-in multi-sensor detects such paper characteristics as thickness, width and skew to automatically make any adjustments necessary for printing. This eliminates the need for paper feeding and other troublesome work that used to burden operators. It also means that operators don't need to touch the printing surface of the paper when loading, which helps keep it free from fingerprints and other soiling. In addition to automatically detecting paper types, the printers can also automatically estimate the amount of paper that has been loaded.

Operators can leave the area after placing the roll of paper in the printer, drastically reducing the time required for setup, simplifying workflows and improving output efficiency.

Automatic Paper Roll Setup Video (23 seconds)

*In order to view videos, it is necessary to consent to the use of cookies by our website. If the videos are not displayed, please click the "Cookie Settings" and accept cookies.

Canon's Unique UVgel Ink Produces Superior Image Quality, Improves Productivity and Supports a Wide Range of Media

Canon's Colorado 1650 large-format inkjet printers for commercial and industrial printing support a wide range of media, including indoor and outdoor advertising such as signages and display advertisements, wallpaper and decorative flooring.

Colorado1650

The UVgel ink used in Colorado 1650 printers combines the advantages of various existing ink technologies. It offers the wide color range of eco-solvent ink, the environmental performance of latex ink—such as its lack of odor—and the high productivity of UV ink.

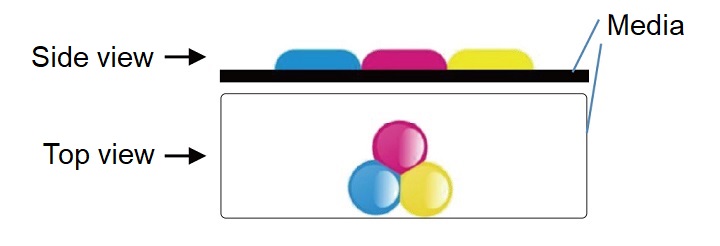

It uses ink temperature control technology to turn the ink into a gel after it is placed on the surface of the media, resulting in accurate dot gain* control. This keeps the ink where it is placed and prevents unintended ink mixing and bleeding. The result is high-quality images with excellent color accuracy, consistency and sharpness.

* The expansion of the sizes of dots when ink is placed on media such as paper.

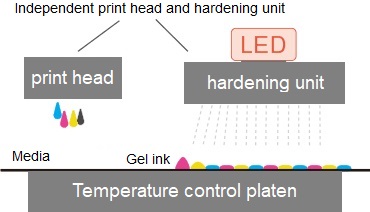

To fully leverage the features of UVgel ink, Canon has placed independent, specialized carriages in the print head and the LED hardening unit.

Unlike conventional UV printers, which repeat the ink ejection and hardening process multiple times, Canon's UVgel ink printers form images and harden in a single pass to print high quality images at overwhelmingly fast speeds.

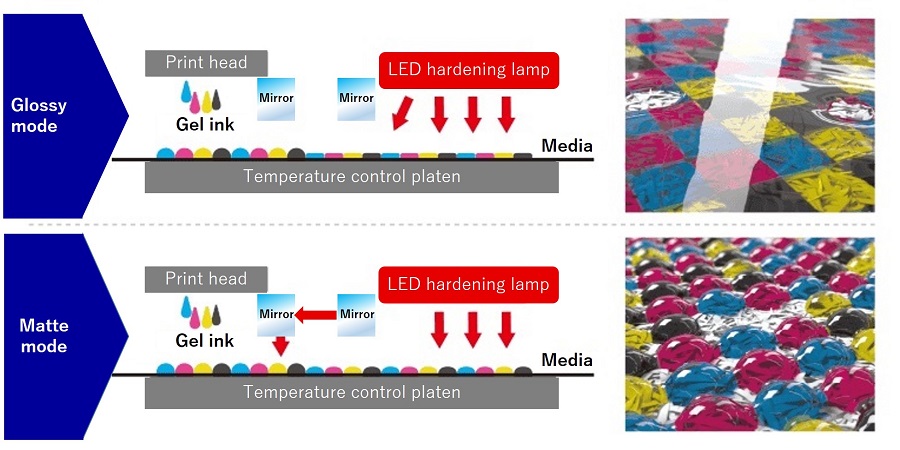

FLXfinish Technology Enables a Single Device to Handle Both Glossy and Matte Finishing

FLXfinish technology makes possible the production of totally different finishes—gorgeous glossy finishes and subdued, sophisticated matte finishes—all without the need to replace ink.

Glossy and matte print finishes are achieved by controlling the timing of the ink hardening. The shape of the hardened ink affects how it reflects light. Differences in hardened ink shapes produce glossy and matte finishes, so users can choose the finish that best fits their printing media.