Our Business

Four Industry-oriented Group

-

Printing

Safe, secure, simple, and convenient prints — anytime, anywhere.

LEARN MORE

-

Medical

Canon supports the development of healthcare through technology in order to promote healthy life.

LEARN MORE

-

Imaging

Creating an array of imaging solutions catering from personal safety and security to abundant lifestyles.

LEARN MORE

-

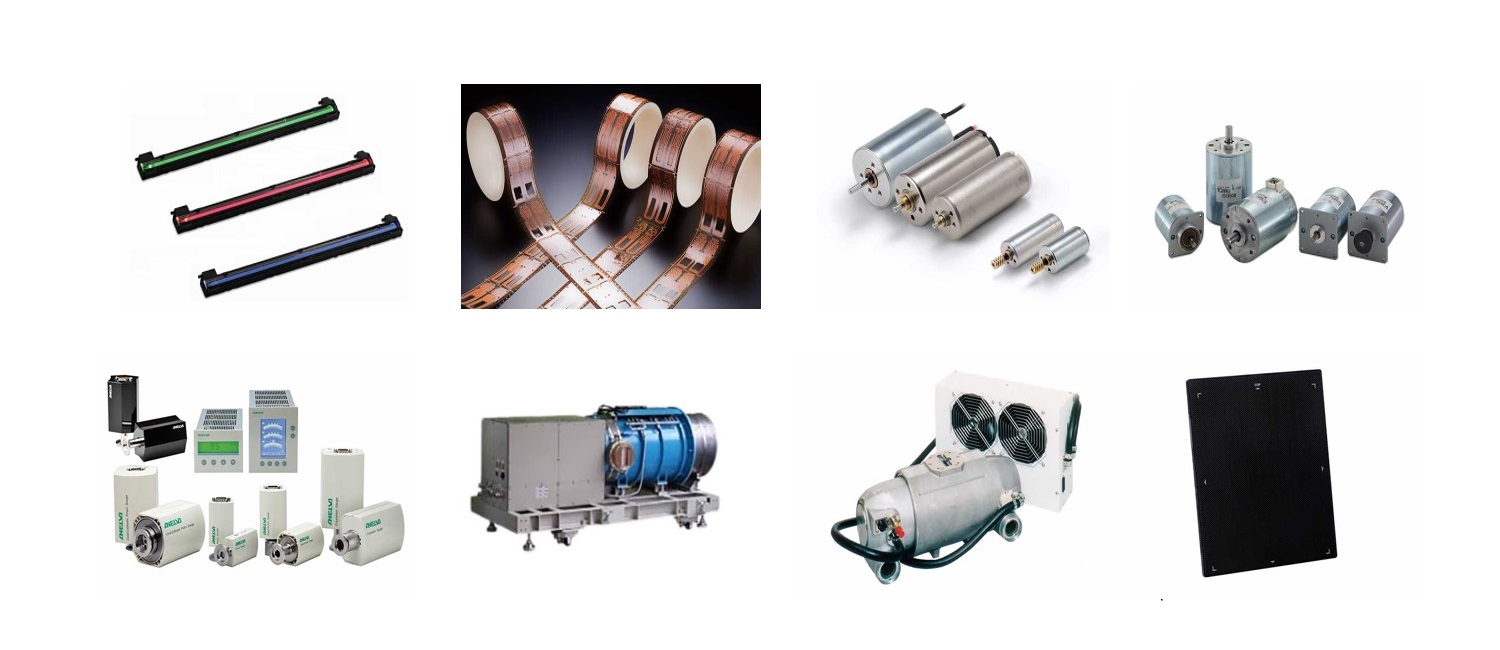

Industrial

Canon's super-precision technology is pushing the leading edge in semiconductors and displays.

LEARN MORE