The exciting future of monozukuri — creating new value

Canon Precision manufactures optical semiconductor sensors and other key electronic components, toner cartridges for laser printers and more. Canon Precision is committed achieving ever-higher standards of quality and performance.

Leading producer of OLED displays featuring vacuum technology

Canon Tokki Corporation has established itself as the premier supplier of production equipment for OLED displays used in consumer products such as smartphones and TVs. A winning combination of team spirit and unique technology is used in the design and manufacture of cutting-edge production equipment such as vacuum deposition machines, together with associated after-sales technical support. Canon Tokki Corporation is dedicated to ongoing innovation in a world of constant change.

Key inkjet production facility

Fukushima Canon produces inkjet printers along with ink cartridges and tanks, and boasts an integrated in-house system encompassing design, manufacture and servicing of production machinery and metal molds. The facility covers a wide range of monozukuri fields including machining, precision assembly and molding, combining expert craftsmanship with IoT technology to create advanced production systems that realize high standards of quality and reliability.

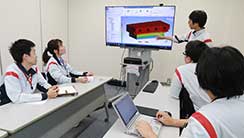

Advanced, high-quality products that support the health industry

Medical equipment represents a major growth area for Canon. Canon Medical Systems plays a key role in the development, manufacture, distribution and after-sales servicing of CT and MRI systems and a range of other medical equipment and devices that deliver improved health and lifestyle outcomes for patients all over the world. While embracing automation and small-lot diversified production approaches, Canon Medical Systems is proud to carry on the tradition of human-led craftsmanship in monozukuri, as exemplified by the Contemporary Takumi (Master Craftsman) system.

Contributing to medicine, industry, and scientific advancement by leveraging technologies developed over more than 100 years

Canon Electron Tubes & Devices has been providing electron tubes and electronic devices with advanced performance and high reliability for more than 100 years since the first X-ray tube was launched in Japan in 1915.

Currently, the company focuses on key components for systems such as X-ray-based medical diagnosis equipment, X-ray-based testing equipment for food and electronic components, and scientific and technological research equipment using high-energy particles. It will continue to provide value to customers by further enhancing its technological and manufacturing capabilities.

The flagship lens factory housing advanced optical technology

The Utsunomiya Plant is Canon's main lens manufacturing facility, producing a wide range of optical products including interchangeable lenses for cameras and broadcast-quality lenses for television studios. This is where top-of-the-line lenses, including the professional-level white telephoto lenses, are individually crafted by skilled technicians. The Utsunomiya Plant has produced many exceptional craftsmen over the years, including a number of Canon Meisters and “Takumi” Master Craftsmen. The facility also implements world-leading environmental initiatives such as 100% water recycling that mitigates the water requirements of lens production.

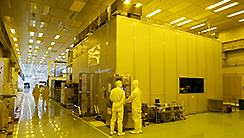

Global supplier of displays and semiconductor chips

The Utsunomiya Optical Products Plant designs and produces lithography systems, which are industrial devices used to make semiconductor chips and display panels. These systems utilize a wide range of Canon's cutting-edge technologies, including large mirrors and lenses, positioning systems and high-speed measuring systems that feature our legendary optical technology and precision machining technology that realizes accuracy on the scale of one-millionth of a millimeter. The plant manufactures large industrial devices, some as tall as a two-story house, in clean rooms where dust and contamination levels are strictly controlled. The Utsunomiya Optical Products Plant is a truly global supplier, providing components and finished devices to leading production facilities all over the world.

Contributing to global industry with advanced plastic mold technologies

Canon Mold specializes in the manufacture of ultra-precise, highly durable plastic molds that deliver exceptional production efficiency. These molds are used in the production of a wide range of products including automobiles, electrical appliances, cameras, office equipment, stationery, food containers, and medical devices. The company also focuses on developing proprietary production and mold technologies, and on nurturing engineers and skilled production personnel to advance these innovations. Canon Mold works to provide the latest technologies and products to meet diverse industry needs as a specialist in mold design and manufacturing.

Creating new value through innovative material technology to contribute to societal development

Canon Optron handles the development, production and sales of optical crystal materials and vacuum evaporation materials as well as sales of coating materials and adhesives for optical use. Canon Optron became the first company in the world to achieve mass production of synthetic fluorite. It made further technological advancements during its efforts to enter the deposition materials market. In 2016, the company also began developing electrolyte material for all-solid-state batteries. It has expanded its business areas through product development focused on stable and safe materials that satisfy environmental regulations and clean energy.

Serving as a production base for Canon's key components

As a production base for Canon's key components, Canon Components manufactures inkjet cartridges and medical equipment. In addition, it conducts its own independent businesses for contact image sensors and printed circuit boards, handling the entire business processes of development, design, production, sales, and patent acquisition.

Printer components are produced in high quality through advanced production technology, while medical equipment components are manufactured with quality assurance in compliance with various laws and regulations.

High purity materials through superior synthesis and purification technology

Fukui Canon Materials produces high-performance materials such as organic electronics materials and OLED display materials, as well as ink for card printers. The company has developed and produced raw materials for organic photoconductors (OPC) used in electrophotographic products, and is now using its synthesis, purification, and mass production technologies to develop and produce high-performance coating materials. As a manufacturer that handles all processes of planning, development, production and sales, the company is committed to developing high-quality products with low environmental impact that meet customer needs.

Contributing to the display and semiconductor industries through efficiency improvements

Ami Plant manufactures modules for semiconductor lithography equipment and those for Flat Panel Display (FPD) Lithography Equipment. Automated guided vehicles (AGVs), which incorporate sensors to recognize their surroundings and drive themselves, have been introduced at this site to improve production efficiency. Canon Semiconductor Equipment and Ami Site of Canon Mold are located on the premises of the Ami Plant.

Manufacturing capabilities that have helped to achieve the world's No.1 share of i-line semiconductor lithography equipment

Here, Canon manufactures i-line semiconductor lithography equipment which has earned it the No.1 share of the global market.

Semiconductor lithography systems are ultra-precise pieces of equipment that require adjustments at the level of a nanometer. CSE provides the advanced technologies and skills necessary to carry out such detailed operations.

Honing its technologies and skills, CSE will contribute to the world by supporting the Canon Group's contribution to the production of semiconductor devices, for which demand is expected to grow over the medium- to long-term for applications such as smartphones, data centers, generative AI, and autonomous driving.

An environmental hub that consolidates reuse and recycling operations across the Group

Canon Ecology Industry is responsible for the reuse and recycling of Canon products such as multifunction devices (MFDs) and toner cartridges. Here, used MFDs are disassembled, cleaned, and remanufactured to be sold under the "Refreshed" series brand. Toner cartridges are converted into recycled material such as metal and plastic using a unique recycling system called "CARS-T"*. Through these activities, Canon strives to effectively use limited resources and contribute to the realization of a circular economy.

Monozukuri of functional polymers, precision molding and machining techniques

Canon Chemicals produces toner cartridges (the core of the laser printer), advanced functional high polymer components (which play a pivotal role in printer performance), and a range of light-blocking coatings and adhesives. The manufacturing division at Canon Chemicals brings together expertise from a wide range of non-chemistry disciplines such as machinery, electronics, physics, information engineering and industrial engineering. Advanced technical expertise in high polymer precision functional components provides a foundation for exploring new developments in other fields.

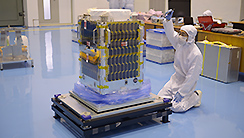

Pushing the boundaries of innovation, backed by genuine "Made in Japan" quality

Canon Electronics supplies an extensive range of products and services—from precision components for cameras and printers to document scanners, portable payment terminals, compact production equipment, medical devices and even space technology such as satellites. The company embraces a holistic approach to monozukuri, where employees are involved at all stages from planning and product development through to production technology, manufacturing and marketing. This approach delivers both high productivity and high quality standards, helping to push the boundaries of innovation in a wide range of areas.

Monozukuri training base and mother factory for office equipment

The Toride Plant is Canon's key R&D and production facility for multifunction office devices and commercial printers. Known as the mother factory for office equipment, it is also the main training base for future monozukuri leaders at office equipment production facilities in Thailand, Malaysia and elsewhere. As Canon's key training facility, the Toride Plant is an important center for Chie-Tech (smart design equipment) and continuous improvement programs.

Training courses are available in such fields as mechatronics and programming, as well as dedicated training sessions for entrants in the National Skills Competition. In this way, the Toride Plant provides a comprehensive grounding in the art of monozukuri.

Streamlined monozukuri that links product development, production, QA and business divisions

Canon Finetech Nisca is a world leader in paper handling systems such as MFP finishers, paper decks and automated bookbinding machines as well as related products including label printers, card printers and DC motors. The company's unique "concurrent” approach combines product development, production, QA and business divisions, enabling products to be brought to market faster while maintaining the highest quality standards.

Supporting production of semiconductor and electrical components with ultra-high vacuum technology

Canon ANELVA handles development, manufacturing, sales, and services related to manufacturing equipment for semiconductors and electronic components, including sputtering equipment, dry etching equipment, wafer bonding equipment, and vacuum gauges.

By relentlessly honing its technology to achieve ultra-high vacuum environments like that of outer space, Canon ANELVA will unlock the future of semiconductors.

A leading innovator in manufacturing technology charts a course of constant evolution

Nagahama Canon manufactures laser beam printers and toner cartridges as well as production-related equipment for semiconductor lithography devices. In 1998, it became the first Canon Group facility to introduce the “cell production” system and quickly established itself as a leading proponent of small-lot diversified production.

Nagahama Canon remains committed to the ongoing evolution of monozukuri through innovations designed to reduce production costs without compromising quality. Examples include automated in-house systems that handle all processes—from product concepts and design to manufacturing—as well as in-house production of molded parts and materials and digitalization of processes from parts inventory and production through to product shipping.

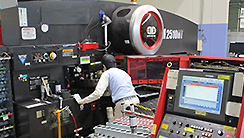

Semiconductor manufacturing systems perfected with automation technologies

Canon Machinery develops, manufactures, and sells die bonders for semiconductor manufacturing equipment used in back-end processes, electronic component-related equipment, and automatic assembly equipment. By harnessing the automation technology it has cultivated for more than 50 years, the company supports the semiconductor manufacturing industry through high-precision, high-productivity bonding of semiconductor chips using micrometer-level* control technology.

*1 micrometer= 1/1,000,000 of a meter

Manufacturing toner for multifunction devices and printers for the global market

Ueno Canon Materials manufactures toner for multifunction devices and printers. Established to meet the growing demand of the digital printing market, the company specializes in producing high-quality toner that delivers outstanding image quality and color reproduction. The facility conducts fully integrated production, including filling and packaging. By incorporating advanced expertise in powder materials and machinery—cultivated over many years—into its production systems, it achieves highly efficient and high-quality manufacturing.

A comprehensive monozukuri facility producing cutting-edge products with cutting-edge technology

Oita Canon is constantly evolving as it pursues world-leading monozukuri, providing a comprehensive suite of products and services including the full range of Canon products as well as key parts and components, automated machinery and equipment (designed and manufactured in-house) and repair services.

Supplying reliable and high-quality products to markets around the world

Oita Canon Materials supplies global markets with toner cartridges for laser printers, ink cartridges for inkjet printers and toner bottles for copy machines and office multifunction devices. The company actively incorporates the latest technological innovations for in-house development and production of components and devices as well as robotics and automation. Oita Canon Materials is committed to providing a vibrant and engaging workplace environment while striving to maintain a competitive advantage on the international stage.

Comprehensive manufacturing facility featuring diversified multi-function production system

Nagasaki Canon is a dedicated manufacturer of Canon camera products for skilled enthusiast and professional photographers, including compact digital, mirrorless, digital SLR and network cameras. As a smart factory boasting the latest automated monozukuri production lines, Nagasaki Canon is a global monozukuri leader with a strong commitment to pursuing the ongoing development of intelligent production systems.

Next-generation production facility championing the future of monozukuri

Miyazaki Canon produces digital SLR and mirror-less cameras, interchangeable camera lenses and professional digital video camcorders. The facility boasts a futuristic new smart factory, launched in 2019, that brings together the combined expertise of the Canon Group. The high-efficiency smart factory can be configured for both large and small production runs and a diverse range of product types.