Many design issues concern phenomena with theoretical mechanisms that are difficult to determine, and it is impossible to reproduce all of them in physical simulations. Canon solves these issues by visualizing the phenomena with high-precision analysis equipment and creating a database of characteristic values to be entered into the simulator.

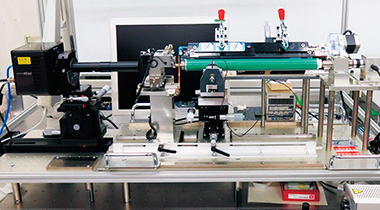

In the example of paper feed simulation mentioned earlier, the actual paper feeding speed varies depending on such factors as the tension acting on the paper, the amount of toner applied, and the presence or absence of paper dust. Since it is difficult to measure these characteristics with high precision using commercially available analysis equipment, we have developed our own analysis equipment and technology.

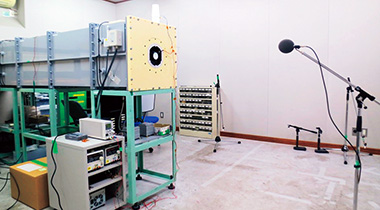

Canon possesses analysis equipment to create databases of various characteristics, such as changes over time in the friction coefficient of paper and rubber, flow characteristics of high-viscosity ink, cooling system characteristics, and acoustic characteristics. Through the use of these databases, we are able to clarify the mechanisms behind the occurrence of defects and incorporate this knowledge in product design, significantly contributing to improvements in product quality.