Canon has been working to better understand the mechanisms of phenomena that cause problems in product development, and to incorporate them into simulation models and product design rules. Based on these achievements, we have developed proprietary Computer Aided Engineering (CAE) and Computer Aided Design (CAD) tools, and accumulated expertise needed to utilize them in higher-level operations. This has been systematized within Canon as “virtual prototyping technology” and is effectively used at design sites to drastically reduce reworking time and costs while continuing to produce high-quality products that support our brand.

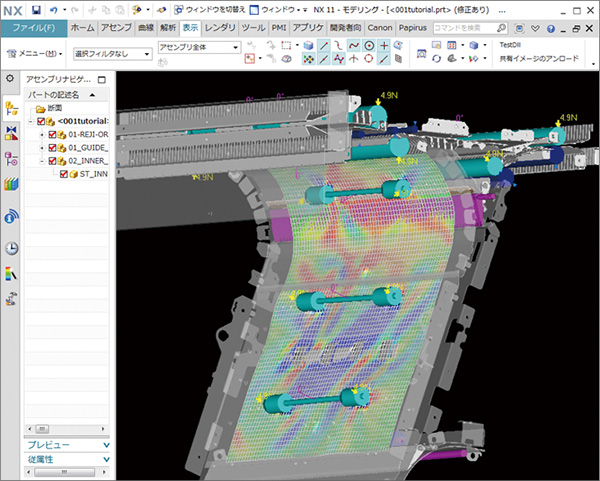

For example, in printer development, there are a variety of issues that occur during paper feeding which must be solved. Canon has developed a proprietary simulator that can check for problems such as paper jams, paper wrinkles, and diagonal movement and even study solutions, enabling design work that doesn’t require physical prototype models.

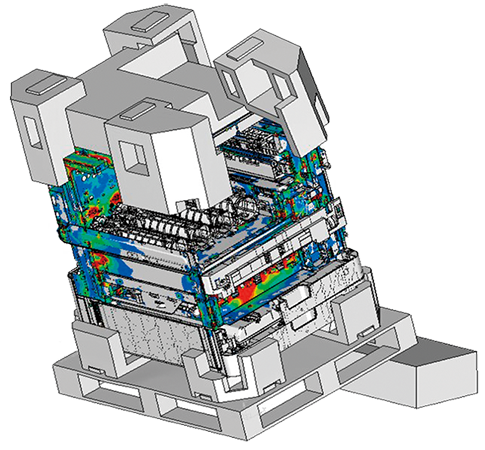

In the past, damage to parts caused by dropping or impact was tested only after completing a prototype model. This meant that once a problem occurred, the design had to be revised during the final stages, which caused delays in the development process.