About the National Skills Competition

The National Skills Competition was launched in 1963 as a way to encourage the development of the next generation of skilled workers. Eligibility is generally restricted to technical workers aged 23 or under, with one participant from each prefecture in Japan. The Competition spans 42 different categories including machinery, construction and services. Canon has been participated in the competition since 2004 as part of our commitment to developing the monozukuri leaders of the future. Participants are generally new employees who have recently graduated high school and express an interest in representing Canon at the Competition.

National Skills Competition—42 categories in six groups

| Group |

Typical categories |

| Mechanics |

Precision machinery assembly, milling machine, lathe working, auto mechanics, clock repair |

| Metalwork |

Car body fabrication and painting, electric welding |

| Construction |

Tiling, plastering, furniture-making, gardening |

| Electronics |

Mechatronics, electronic device assembly, factory machinery and equipment |

| ICT |

Web design, IT network systems |

| Services/fashion |

Flower arrangement, hairdressing, cake making, Japanese cuisine |

Prefectural level

Held in all 47 prefectures in Japan. Entrants must be 23 or under. Overall winner goes on to represent their prefecture at the national level.

National level

Annual competition with representatives from the 47 prefectures. Winners receive gold, silver or bronze medals or meritorious achievement awards.

International level

The World Skills Competition is held every two years, with participants chosen via national competitions around the world.

Canon represented in four competition categories

Of the 42 categories in the National Skill Competition, Canon is represented in four categories related to manufacturing skills and expertise required in the Group: milling, precision machinery assembly, mechatronics and electronic device assembly.

New employees take on the challenge

The winners of the 63rd competition

The players are selected from among new employees who have recently graduated high school. The selected employees, who volunteered to strive for victory in the competition, are committed to acquiring advanced technical skills so that they can contribute to improving Canon’s manufacturing capabilities.

Physical, mental and technical development

Those who have been selected participate in training divided according to competition categories. Trainees are coached by skilled workers with years of experience and participants from previous years, who provide advice and guidance on areas of particular concern and may also act as personal mentors during the daily sessions. The challenging training regimen to develop the required level of technical prowess starts from basic principles before branching off into respective fields of specialization tailored to the individual’s level of competence. Trainees are also given opportunities to develop mental strength by working on tasks from previous competitions, training in the presence of observers and undertaking joint training sessions with other companies.

Through a combination of physical training for stamina, mental training for strength of mind and a comprehensive skills development program, trainees prepare themselves for the ultimate challenge of demonstrating their prowess at the National Skills Competition.

Three years of preparation enables them to reach high levels of technical skill. As a result, they tend to perform very well in the workplace even after the National Skills Competition ends.

The four categories chosen by Canon

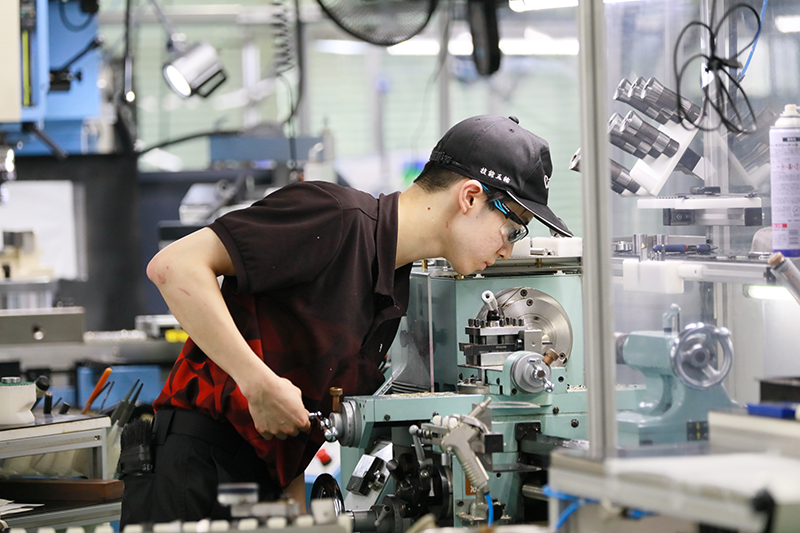

Milling

Competitors use a machine tool called a "milling machine" to compete on their ability to shave materials. They choose a cutting tool according to the workpiece, and they make holes and cut grooves to finish the required shape. The assignment of the competition is announced in advance, and the competitors consider the best processing method before entering the competition. The task involves fabricating four metal components to a machining accuracy of 0.01 mm or better, then assembling them into a working product, within the allotted time.

Competition task

The task involves fabrication and assembly of four metal components

Initial workpieces

Finished components

Assembled product

Precision machinery assembly

Competitors are tasked with fabricating some 20 differently shaped components from such materials as iron and brass using three types of metal cutting and working machine tools (milling machine, lathe and surface grinder) as well as hand finishing by rasp or file, then assemble the parts and adjust as necessary. Task requirements are published in advance to allow competitors time to prepare strategies and methodologies; however, the task is then modified slightly on the day of the competition, such as with changes to design drawings, in order to assess competitors’ ability to adapt to change. Components must be fabricated to a precision of 0.001 mm—one-hundred times smaller than the width of a human hair—within the allotted time.

Competition task

The task involves machining and assembly of around 20 components

Initial workpieces

Finished components

Assembled product

Mechatronics

Competitors work in pairs to assemble supplied components such as sensors, motors and robot arms in accordance with a set of specifications and drawings, only made available on the day of the competition, to produce a finished automated workstation. They are judged on the speed and accuracy of automation skills including machinery design, assembly and programming. Once the challenge is finished, competitors are given a further two days to make improvements and enhancements in accordance with instructions. This requires a teamwork-based approach, with the two competitors pooling their skills and expertise to devise solutions to whatever problems the task comprises.

Competition task

The task involves building and programming equipment

Make a workstation

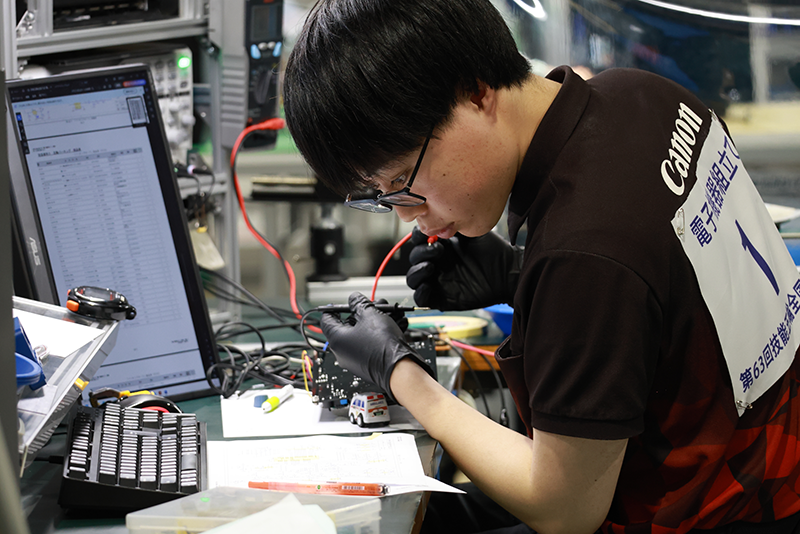

Electronic device assembly

Competitors are judged on their design, assembly and programming skills with electronic circuit boards for industrial products. There are three tasks to complete: based on a set of unseen specifications, use CAD (computer aided design) software to produce design drawings, assemble an electronic circuit using solder and program the electronics; use measuring and testing devices to identify and then rectify faults in a supplied defective product; and task devoted to programming. Scores on each task are aggregated and used to obtain the final rankings.

Competition task

The task involves making an electronic device and includes soldering

National Skills Competition alumni drive monozukuri improvements

Active in the National Skills Competition

Canon began participating in the National Skills Competition in 2004, twenty years ago. Canon employees who have taken part in the Competition over that period have gone on to play leading roles in their workplaces. The qualities of perseverance, determination and adaptability required for success at the Competition empower them to drive change and improvement in monozukuri at Canon and leave a positive legacy for future generations.

Active as a team leader

The 63rd National Skills Competition

A Bronze Award in Mechatronics

At the sixty-third National Skills Competition, held from October 17 to October 20, 2025, the two-member team from Canon won a Bronze Award in the Mechatronics category. In addition, two other Canon contestants received Fighting Spirit Awards, one in the Electronic Equipment Assembly category and the other in the Precision Equipment Assembly category.

Canon has now won awards in the National Skills Competition for twenty-one consecutive years since the forty-third competition in 2005.