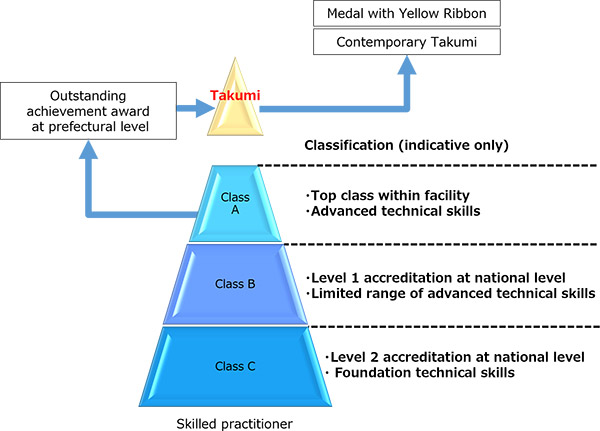

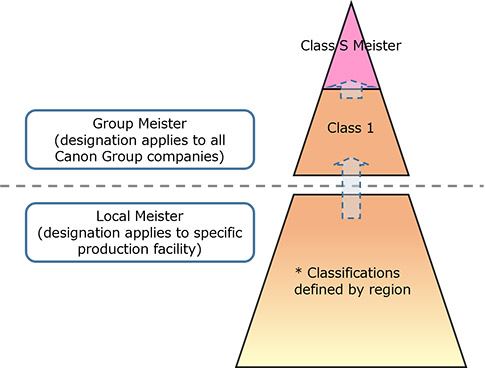

At Canon, the terms Takumi and Meister are used to denote people with outstanding skills and experience in particular areas of expertise who have been identified as potential monozukuri leaders in the workplace. A Takumi is a person with exceptional skills and experience who performs a certain task or tasks at a much higher level than all others, while a Meister is a multi-skilled worker with a broad range of skills and knowledge across multiple processes. As we increasingly move toward automation of production processes, it is the Takumi and Meisters who will guide the future direction of monozukuri at Canon.