The Environmental Approaches and Initiatives of Four Business Groups

Initiatives of the Industrial Group

At the Industrial Group, our mission is to support the future of humanity and the world through manufacturing innovations. To achieve this, we utilize our groundbreaking industrial machinery to co-create new values with our customers. By integrating proprietary optical and image processing technologies, refined over many years, into our industrial equipment, we have developed products that meet the diverse needs of the industrial sector.

Goals

Decarbonization (reducing CO2 emissions)

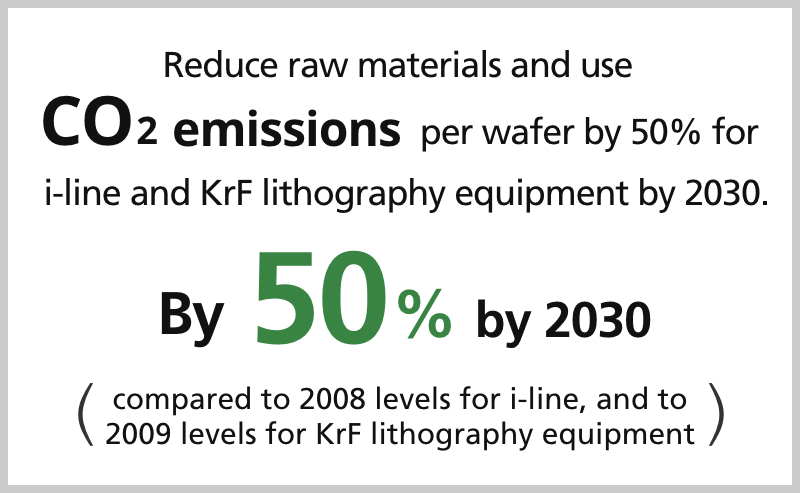

We aim to reduce per wafer raw materials and operational CO2 emissions in our i-line lithography equipment*1 and KrF lithography equipment*2 by 50% by 2030 (compared to 2008 levels for the i-line, and to 2009 levels for the KrF lithography equipment).

We aim to reduce per panel raw materials and operational CO2 emissions in our 8th generation FPD lithography equipment by 50% by 2030 (compared to 2008 levels).

- *1: FPA-5550iZ series

- *2: FPA-6000ES6a series

Resource Efficiency (extending product lifespans)

We are working to extend the lifespans of our products. Our goal is to ensure that 95% or more of the i-line and KrF lithography equipment shipped in 2001 or later is still active by 2030.

Strategy

Decarbonization

Since operational CO2 emissions account for the majority of the lifetime CO2 emissions of our products, we are working to reduce operational energy consumption.

Given that cutting-edge logic semiconductor production plants consume large amounts of electricity, we plan to install energy-efficient nanoimprint semiconductor manufacturing equipment.

Resource efficiency

By providing the parts and software required to extend the lifespans of our products, we help reduce waste. We are also working to develop products that encourage recycling.

Raw materials and use CO2 emissions per wafer

Measures

1. Measures for raw materials - Semiconductor Lithography Equipment

Through the use of 3D modeling, we have reduced the size and weight of our parts and therefore reduced the volume of raw materials required.

1. Measures for Raw Materials / 3. Logistics / 4. Use & Maintenance - Sputtering Equipment

By reducing product size, we achieved a 13% reduction in material usage and cut transportation-related CO2 emissions by 13%. By redesigning the cooling mechanism, we reduced CO₂ emissions from energy sources by 24%.

2. Measures for production

We have achieved a 20% reduction in energy use through energy network tie-ups with other companies.

4. Measures for use and maintenance - Semiconductor Lithography Equipment

Through the use of regenerative energy, we intend to optimize our energy use and reduce energy consumption during peak times.

4. Measures for use and maintenance - Semiconductor Lithography Equipment

We intend to reduce energy loss during transmission by ensuring compatibility with high voltages, and so reduce our energy consumption.

4. Use & Maintenance - FPD Lithography Equipment

By replacing the conventional mercury lamp illumination with newly developed LED lighting, we have reduced the product's energy consumption by approximately 10%.

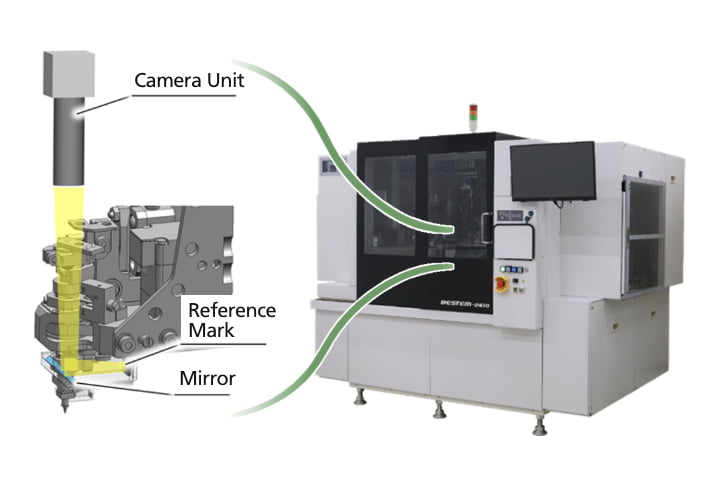

4. Use & Maintenance - Die Bonder Equipment

By incorporating high-speed linear motors and a function to compensate for thermal expansion, we improved productivity by 35% and enhanced energy efficiency by 18%.

4. Use & Maintenance - OLED Manufacture Equipment

By developing high-speed robots, we will shorten machine time for substrate transfer and continue to improve productivity.

5. Measures for disposal and recycling - Plastic Sorting Equipment

Through the launch of the TR-S1510 Raman Plastic Sorter, we intend to promote recycling.

5. Measures for disposal and recycling - Semiconductor Lithography Equipment

We intend to extend the lifespans of our products by providing new electronic parts and software for existing equipment.