Climate Change

CO2 Reduction through Initiatives at Operational Sites

Canon thoroughly tackled the reduction of CO2 emission during operation. Through the group-wide actions including painstaking energy management and regular checks of equipment status and operating settings, we pursue the improvement of energy efficiency.

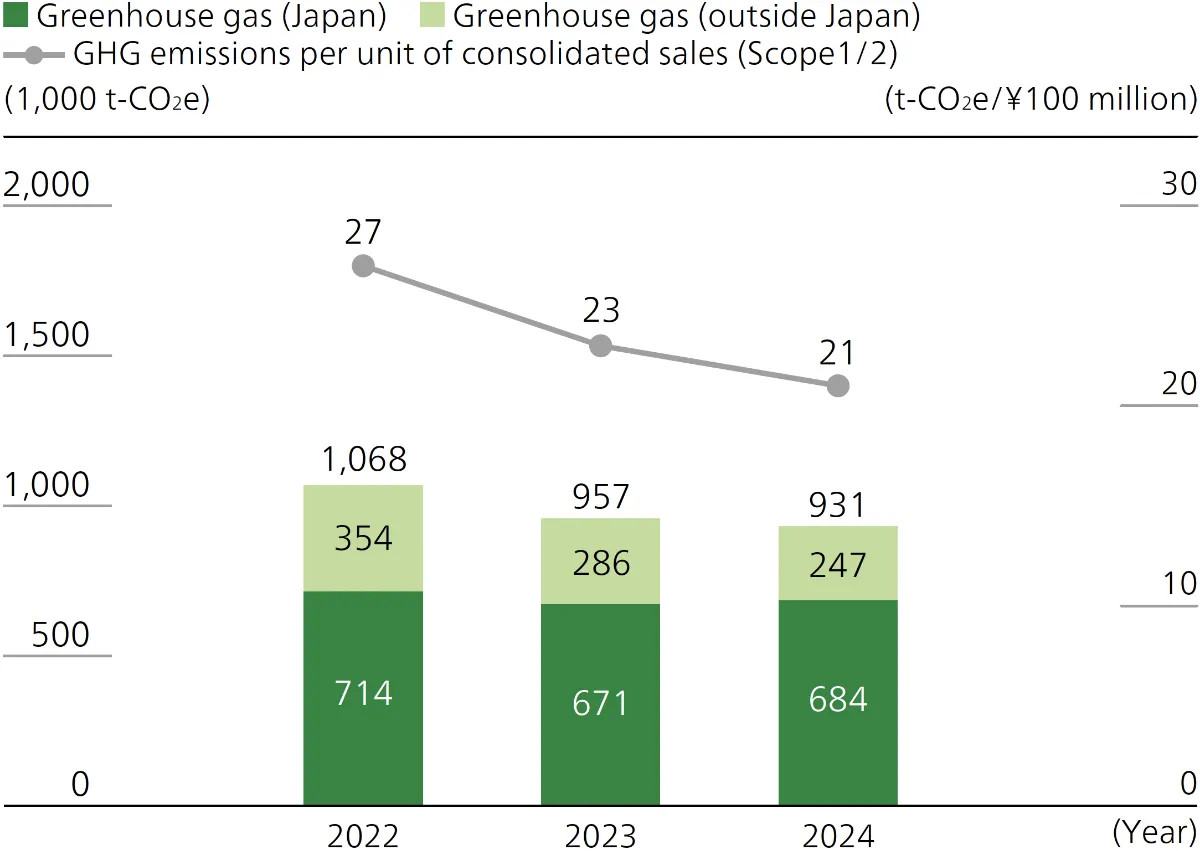

Greenhouse Gas Emissions at Operational Sites

The efforts of the Energy Cost Reduction Working Group, coupled with the rigorous streamlining of production processes and other actions by our operational sites to reduce energy use and adopt renewable energy, resulted in an approximately 2.7% year-on-year reduction in GHG emissions at operational sites, to 931,000 t-CO2e. In 2025, we will push ahead with efforts to reduce CO2 emissions, mainly by saving energy and utilizing renewable energy sources at our business locations.

Greenhouse Gas Emissions at Operational Sites

Greenhouse Gas Emissions at Operational Sites

Greater Energy Efficiency at Operational Sites

Cutting Power Consumption in Production Using Production Green Cost Management (GCM)

Reducing Power Consumption in Production Using Production Green Cost Management (GCM) At Canon, we use "GCM" to refer to the management framework we have developed that targets parallel reductions in costs and CO2 emissions, alongside decarbonization efforts based on the development of green technologies. Within this framework, we focus on "production GCM" initiatives that aim to reduce the power used at the production stage. In production GCM, factory's energy data is automatically collected and plotted in graphs (visualization of electricity) through established systems, which has facilitated not only the instant identification of wasteful operations (analysis of reduction potential), but also the systematic accumulation of data across the entire company, thereby enabling the immediate discovery of appropriate reduction measures (expansion of reduction measures).

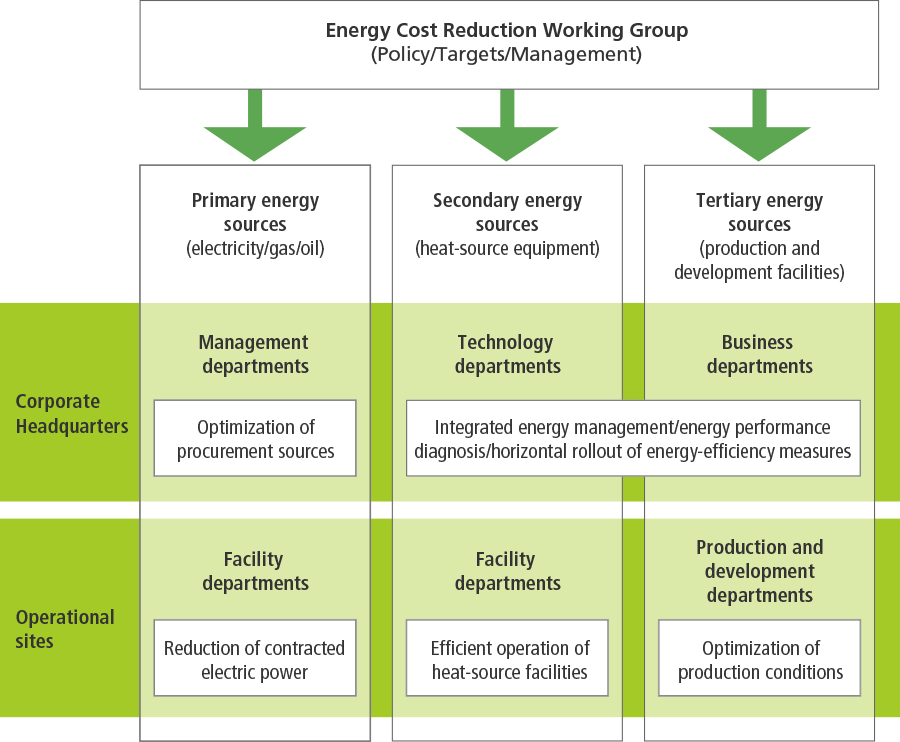

Energy Cost Reduction Working Group

Canon created the Energy Cost Reduction Working Group in 2014 as a horizontally integrated organization to take Group-wide action on reducing energy consumption. The working group has promoted reduced energy consumption by undertaking a thorough-going analysis of the required operating environment for production equipment in the on-site manufacturing process and using its findings for instance to reduce equipment operating time, cut out excess use of pressurized air and cooling water, and adjust air conditioner settings. Measures that prove effective are adopted for horizontal rollout to Japan and overseas production sites. Moreover, staff members from our corporate headquarters in charge of this initiative perform a diagnosis of energy performance during visits to production sites all over the world. There, they check the operating status and settings of production equipment and then use their observations to make improvements to the operating efficiency of facilities and equipment and provide staff with relevant on-site training.

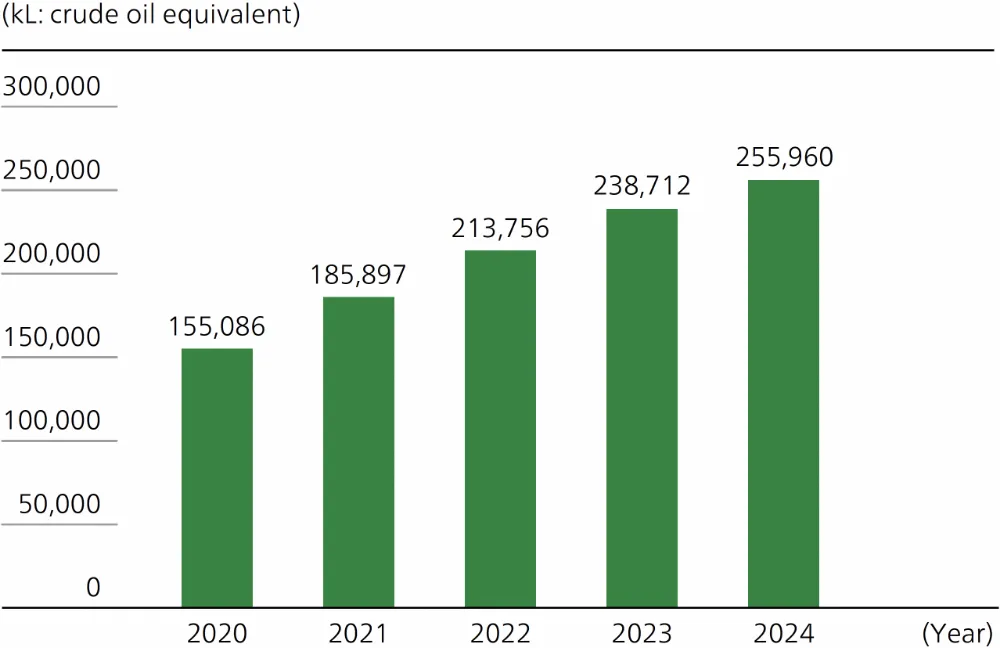

Since its launch, this initiative has resulted in Canon wide energy savings of 255,960 kL (crude oil equivalent).

| Measures widely rolled out in 2024 |

|---|

| Upgrades to high-efficiency air-conditioning units |

| Changes to washing water temperature |

| Insulation for molding machine cylinders |

Initiatives at Operational Sites

Public-private efforts for energy-saving and CO2 reduction

In a joint undertaking in Utsunomiya City, Tochigi Prefecture, with the prefectural authorities and three other companies*1, Canon launched the Kiyohara Industrial Park Smart Energy Project, realizing major energy savings. The project integrates the Kiyohara Smart Energy Center and other sites newly established within the Kiyohara Industrial Park. By sharing use of electric power and heat (steam and hot water) between multiple business sites with differing levels of demand, the project achieved reductions per base unit of approximately 20% in energy consumption and 20% in CO2 emissions volume*2—which would not be possible for a single business site alone. In recognition of this initiative, Canon jointly received the Ministry of Economy, Trade and Industry Joint Implementation Award under the 2021 Energy Conservation Grand Prize sponsored by the Energy Conservation Center, Japan. Moreover, In 2023, in the 31th Grand Prize for the Global Environment Awards, sponsored by the Fujisankei Communications Group in Japan, the Minister of Economy, Trade and Industry Award was jointly presented.

In 2023, a system to predict and visualize the excess steam power generated from waste heat made it possible to use excess heat more effectively by introducing steam power facilities and making other operational improvements. These are expected to bring further benefit with an increase of two percentage points or more in energy-saving and CO2 reduction

- *1 Calbee, Inc., Hisamitsu Pharmaceutical Co., Inc., and Tokyo Gas Engineering Solutions Corporation

- *2 Reduction realized by electricity and heat sent from cogeneration facilities compared to fiscal year 2015 before project launch Fiscal year 2021 performance: approx. 10,400kL/year reduction in crude oil equivalent; approx. 21,000t/year reduction in CO2 emissions