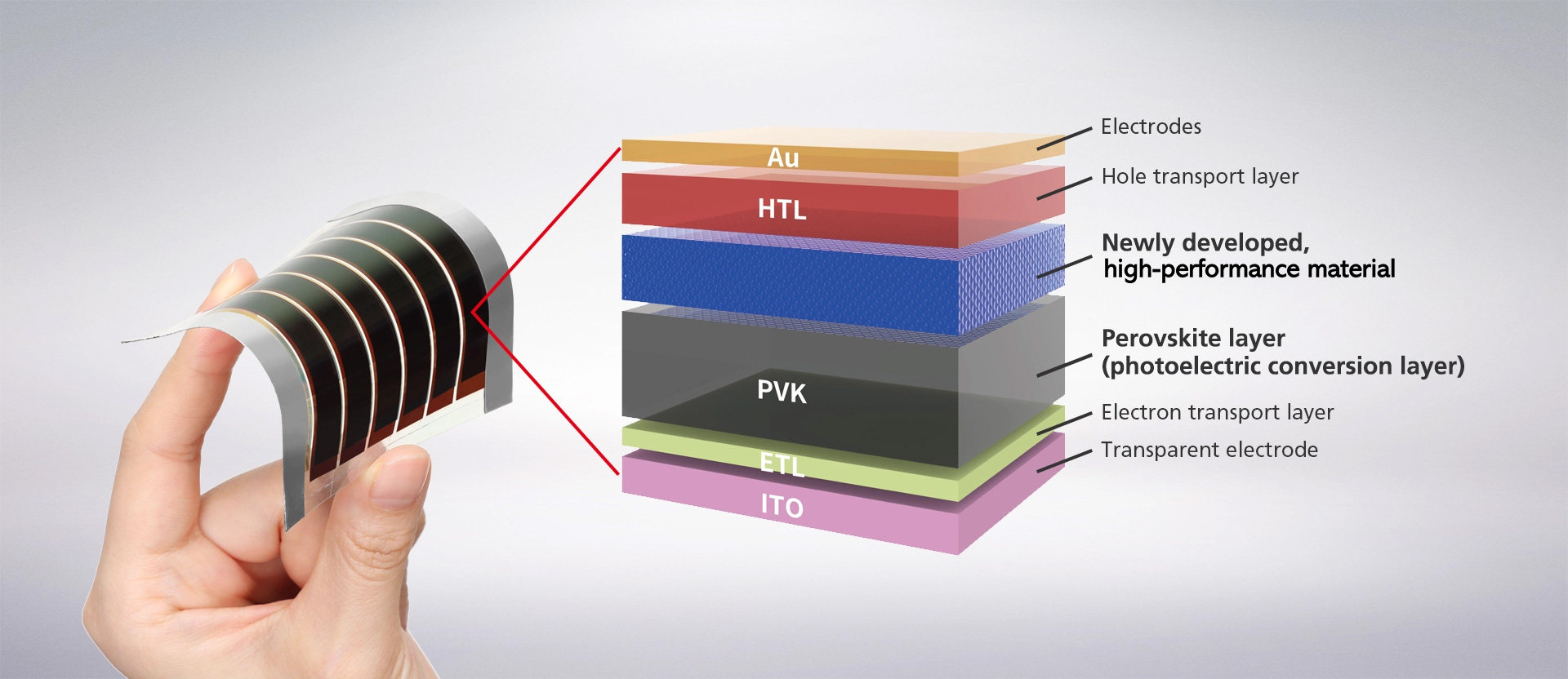

A game-changing breakthrough toward the commercialization of thin, lightweight, and bendable next-generation solar cells

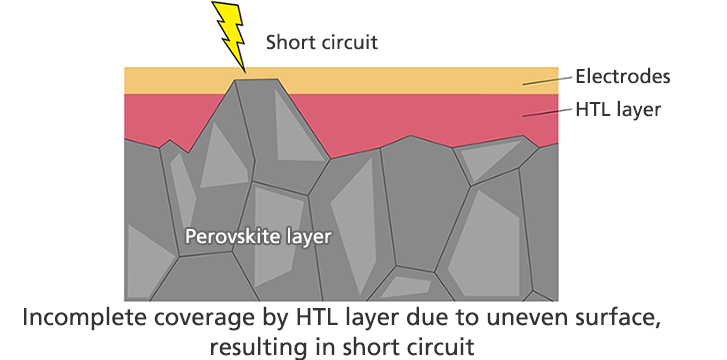

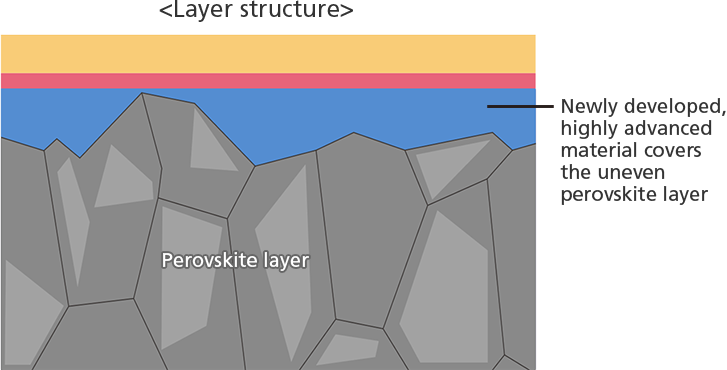

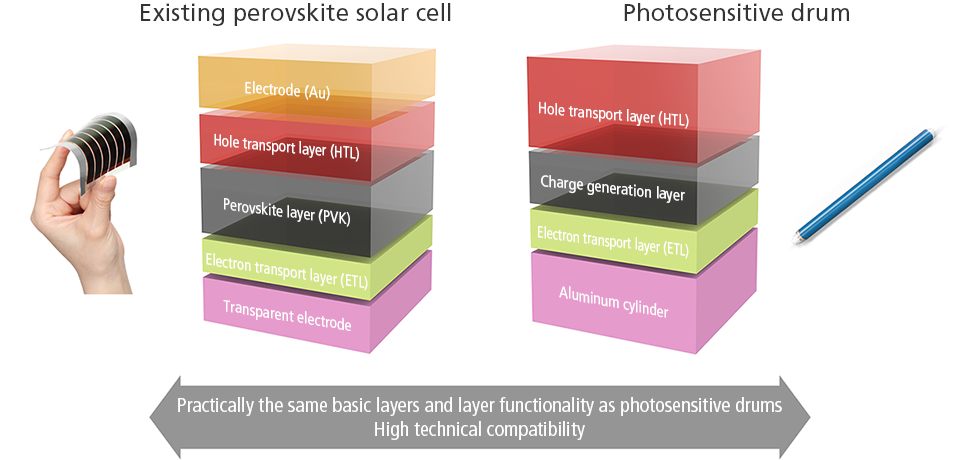

A high-performance material for perovskite solar cells

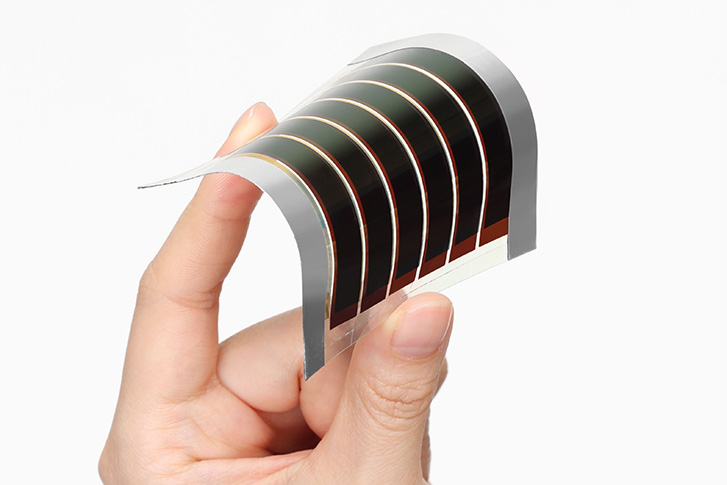

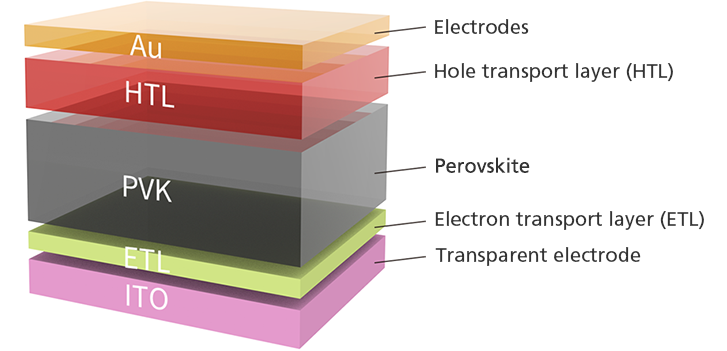

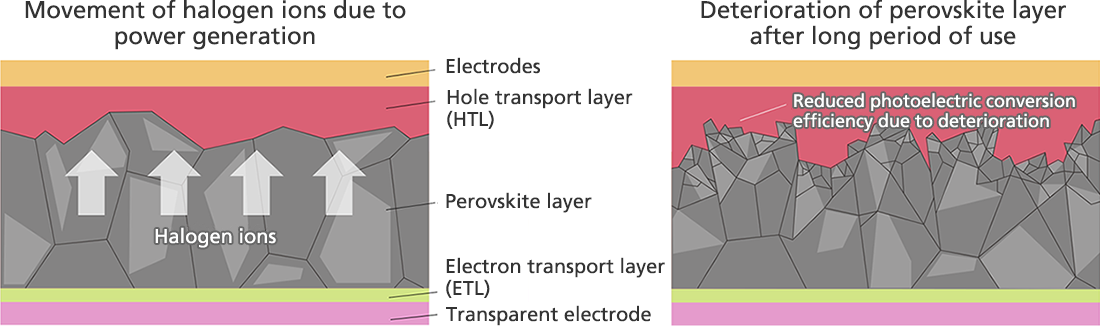

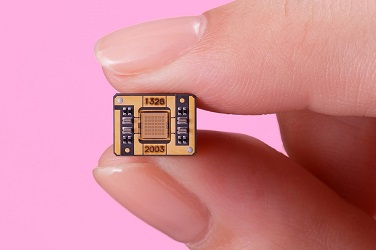

Perovskite solar cells have captured attention for their bendability. Now, Canon has made game-changing breakthroughs by developing a new high-performance material that improves their durability and mass-production stability. The high degree of flexibility over where these solar cells can be installed, which includes the walls and windows of buildings and homes, helps increase the accessibility of solar energy sources.

February 25, 2025