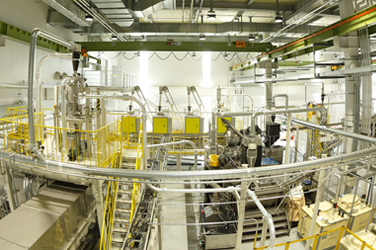

Supporting a Circular Economy by Facilitating Sorting Operations Through New Technology

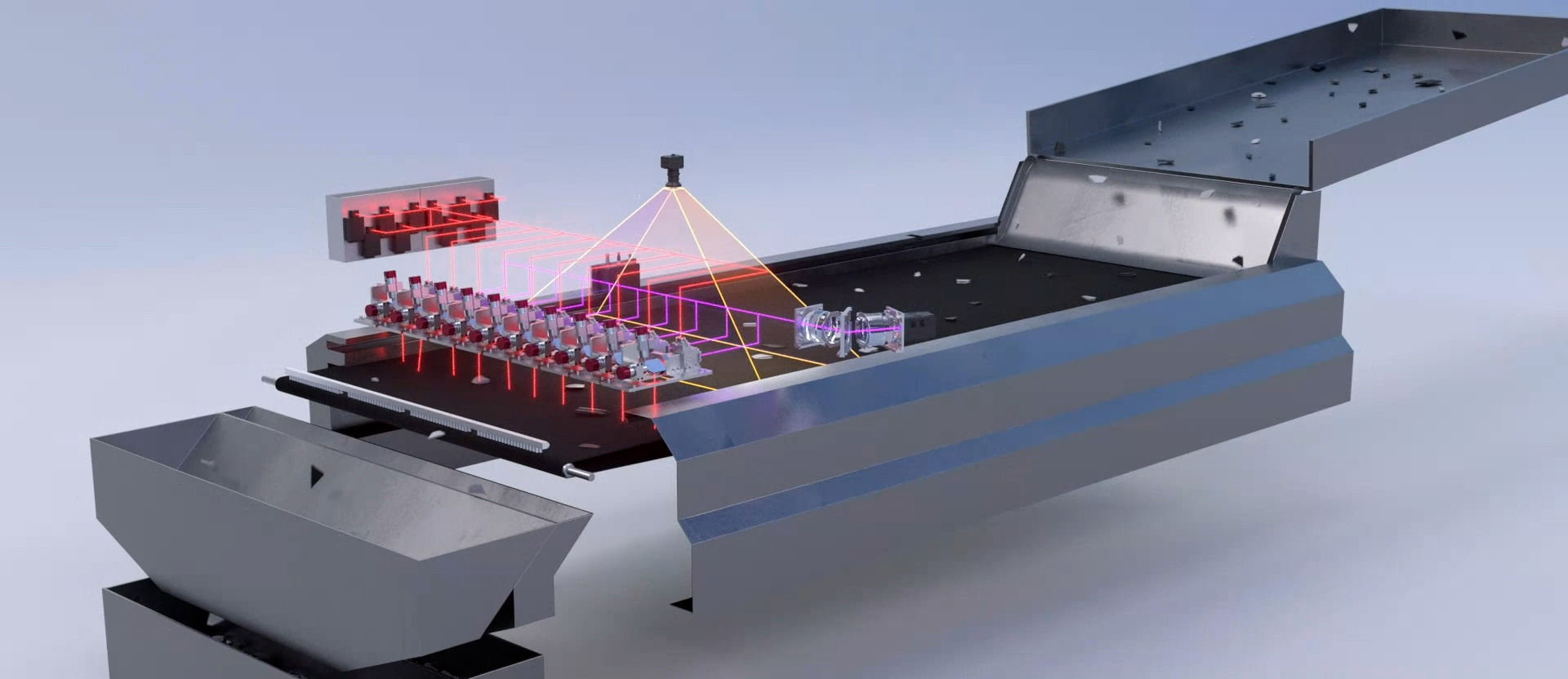

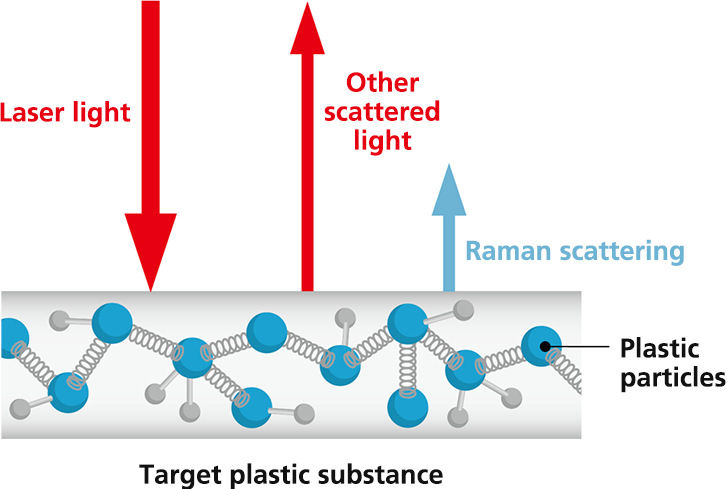

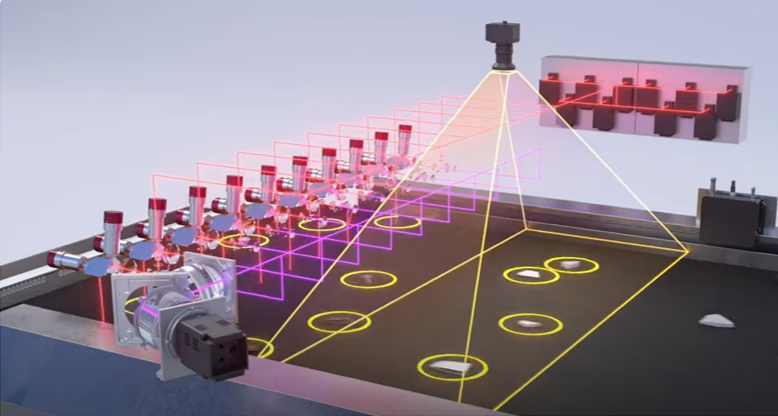

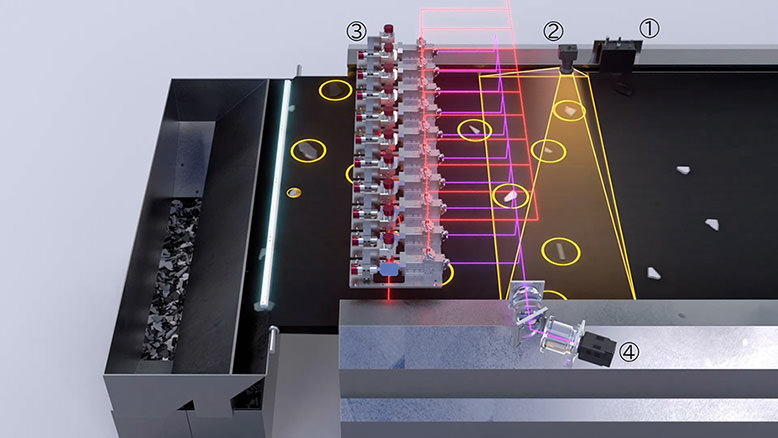

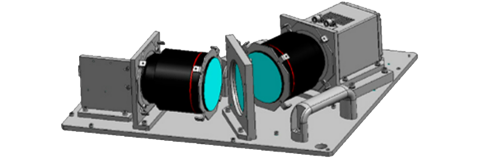

Raman Spectroscopy Technology for Sorting Black Plastic Pieces

Black-colored plastic is used in many items around us including home electronics and automobile upholstery. Unfortunately, however, it has been difficult to identify the material type of black plastic at recycling centers. To address this issue, Canon has developed an accurate plastic sorting technology that can handle black plastic pieces and those in other colors simultaneously. The new technology will help to maximize the volume of recycled plastic by making sorting more efficient.

November 26, 2024