Probing the Mysteries of the Distant Universe with Proprietary Canon Technologies

Prime-Focus Corrector for the Subaru Telescope

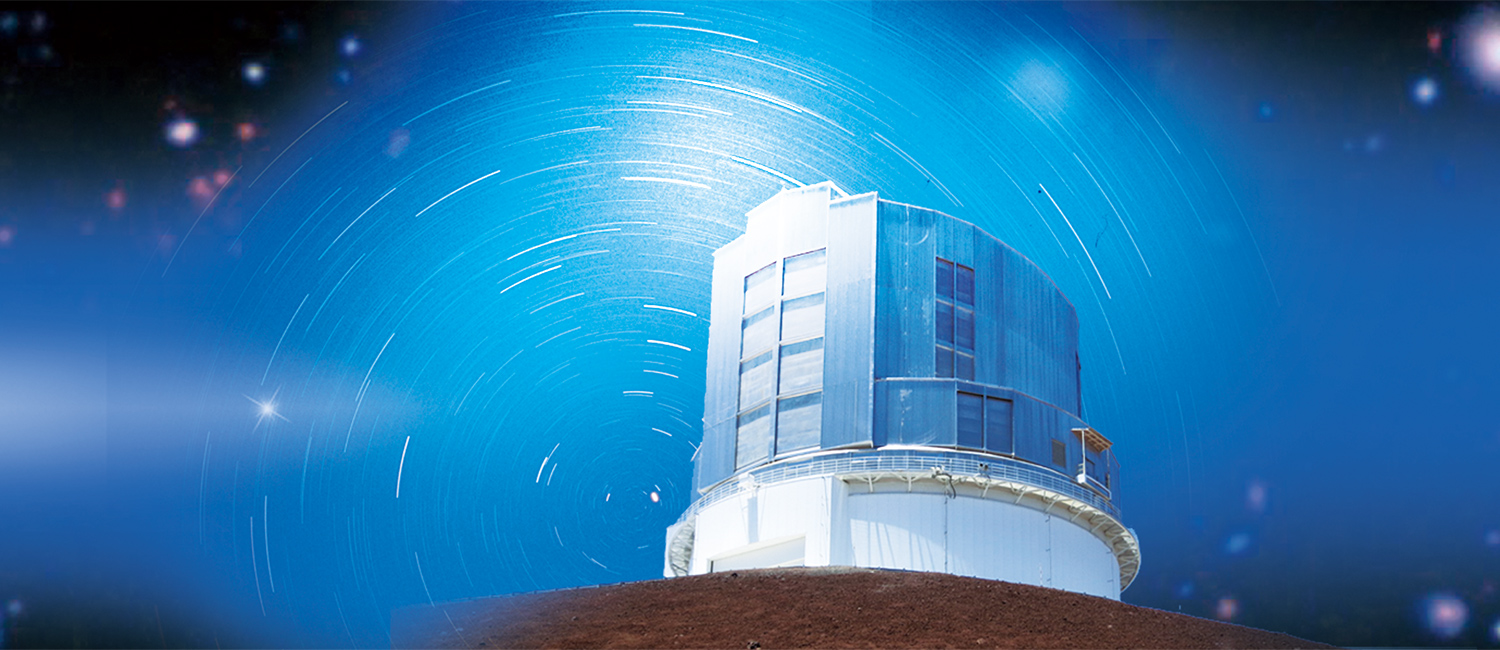

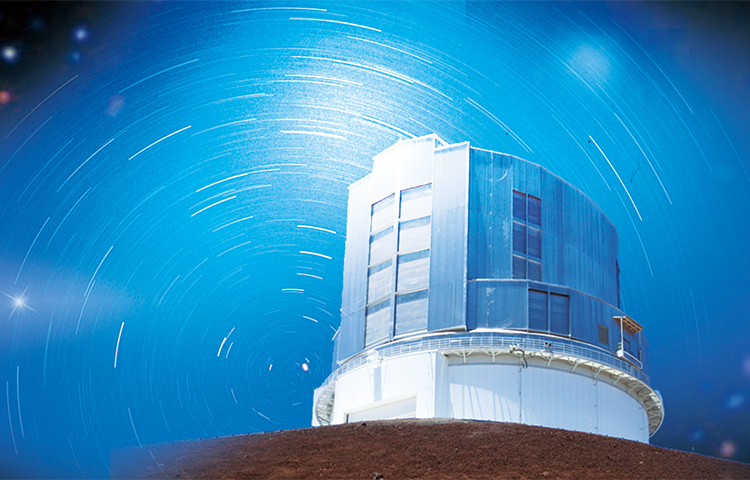

Humanity has long wondered how the universe began and how it will end. Dark matter and dark energy might help us unlock secrets of the universe that long predate the birth of humankind. Astrophysicists are unraveling the true nature of dark matter and dark energy with the Subaru Telescope, located atop Mt. Mauna Kea on the island of Hawaii. Canon's proprietary optical, measurement and high-precision processing technologies have greatly improved the performance of the Subaru Telescope and helped to accelerate the progress of this project.

December 27, 2018

Capturing a Galaxy Approximately 13 Billion Light-Years Away from Earth

The galaxy known as SXDF-NB1006-2 is 12.91 billion light-years away from Earth.1 Light from this galaxy travels inconceivable distances to reach our planet. The galaxy began emitting light about 750 million years after the Big Bang brought about the birth of the universe (approx. 13.7 billion years ago), long before our own planet came into being (about 4.6 billion years ago). The Subaru Telescope is capable of capturing faint light signals from the distant reaches of the universe, including this galaxy, and transforming them into sharp images observable to humans. Operated by the National Astronomical Observatory of Japan (NAOJ), the Subaru Telescope is at the forefront of space research.

- 1 SXDF-NB1006-2

The Subaru Telescope and Keck Telescope discovered SXDF-NB1006-2, a galaxy located 12.91 billion light-years from Earth (announced on June 4, 2012, by the NAOJ).

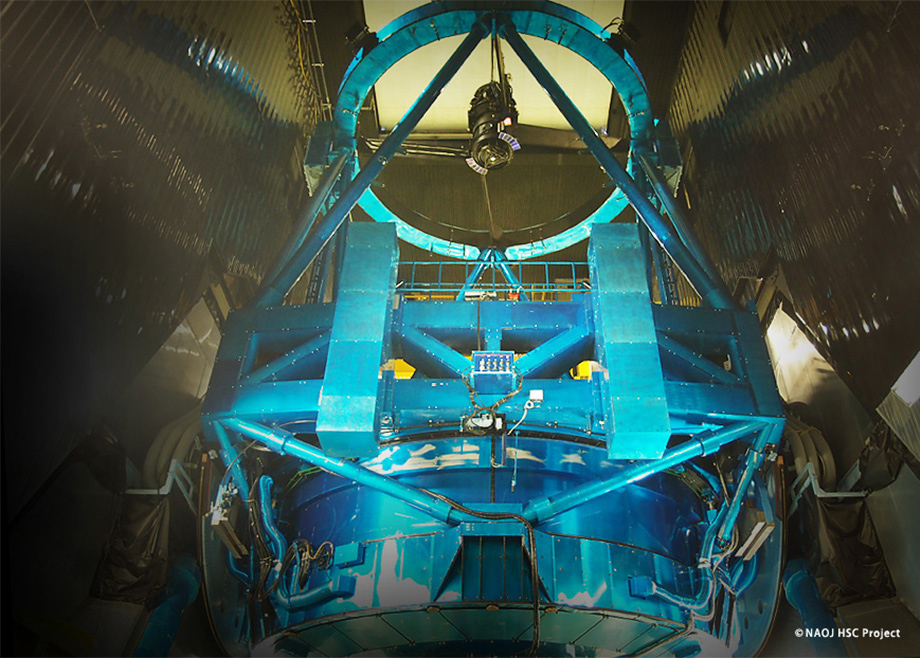

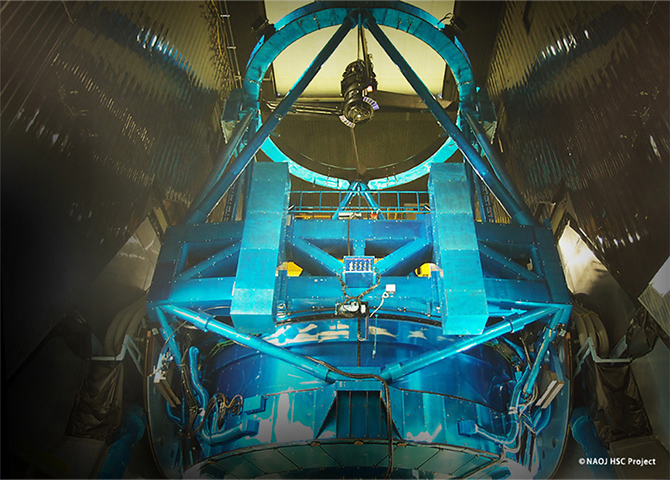

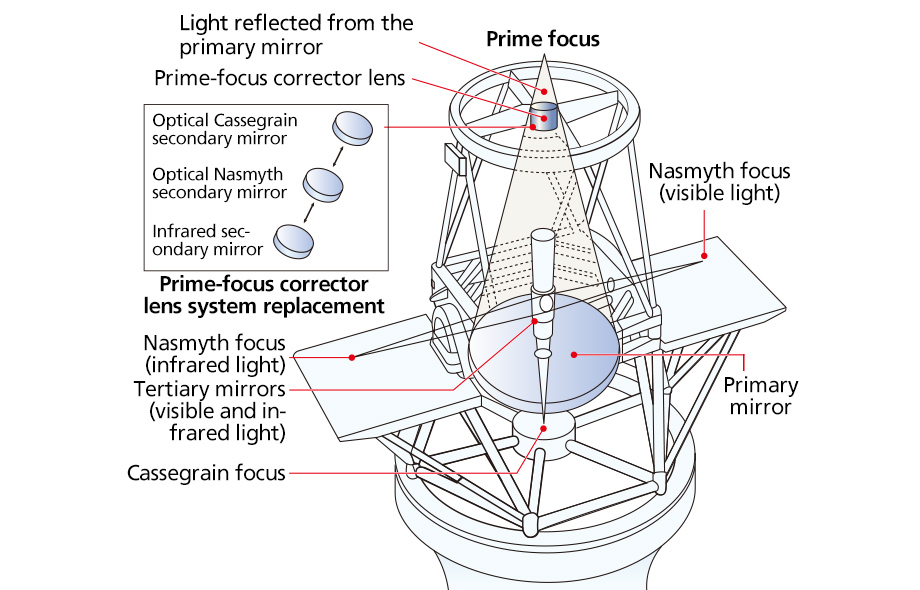

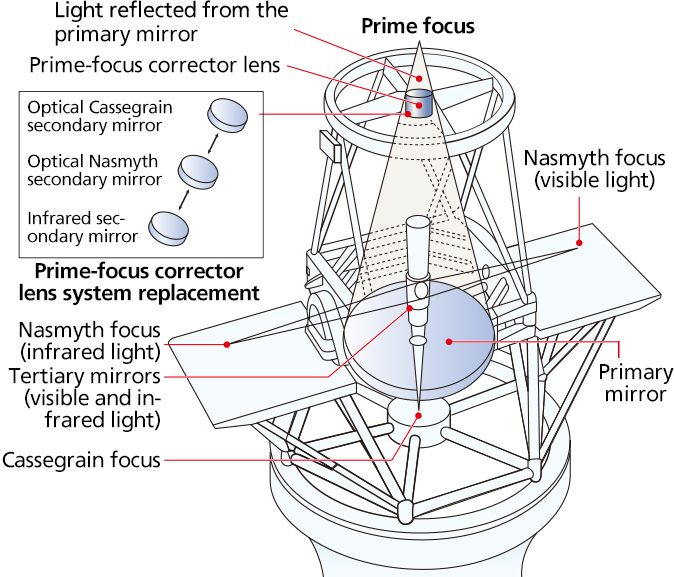

Overall Structure of the Subaru Telescope

The most notable feature of the Subaru Telescope is that it is unique among 8-meter-class telescopes for incorporating an observational instrument at prime focus. The observation system's Suprime-Cam (SC) is equipped with a prime-focus corrector, a complex lens unit developed and manufactured by Canon. The prime-focus corrector not only corrects for light aberrations from the primary mirror, but also includes a function that corrects for the atmospheric dispersion of stellar light, delivering high-performance imaging and a wide field of view measuring 0.5 degrees, approximately equivalent in size to the diameter of the moon. Since its first light in 1999, these features have helped the Subaru Telescope achieve numerous impressive accomplishments.

Seeking Insights into Dark Matter and Dark Energy to Unlock the Secrets of the Universe

#Imaging technologies#Social contribution#Space#Physics

Since 1999, research into space and astrophysics has been progressing rapidly. We have discovered that only a small percentage of the universe is composed of the atoms and other forms of matter that we know of, whereas dark matter and dark energy, which account for most of the universe, are still a mystery to humankind. By studying and clarifying the true nature of these phenomena, we expect to find promising clues about the origins and future of the universe. Astrophysicists hope to accelerate their research efforts by using observation systems offering fields of view that are wider than the Subaru's SC (Suprime-Cam).

The NAOJ has worked to develop an ultra-wide-field prime-focus camera called the Hyper Suprime-Cam (HSC). The new HSC offers an expanded field of view to enable the observation of more galaxies, including distant ones that emit little light, across a broader region of the universe in a shorter amount of time. Observations by the HSC will help scientists calculate the dimensions of galaxies with higher accuracy and create 3D spatial distribution maps of dark matter based on distortions of stellar images caused by the effect of gravitational lensing.2 These advances are expected to shed light on the true nature of dark matter and dark energy.

Canon was in charge of developing and manufacturing the corrector for the HSC ultra-wide-field prime-focus camera. In order to install the HSC into the existing configuration of the Subaru Telescope, the company had to design the prime-focus corrector under severe weight and dimensional constraints. Tougher still, Canon also had to achieve a targeted field of view of 1.5 degrees without exceeding these constraints. The HSC's ultra-wide field of view is triple that of the SC, wide enough to capture the equivalent of three full moons at once.

- 2 Gravitational lensing

A phenomenon in which light rays from fixed stars, galaxies, and other celestial bodies appear to bend and distort relative to the observer or split into duplicate images due to the gravitational pull of celestial bodies situated in the path of the light rays.

Exceptional Optical, Measurement and Processing Technologies

#Social contribution#Space#Mechanical engineering#Physics

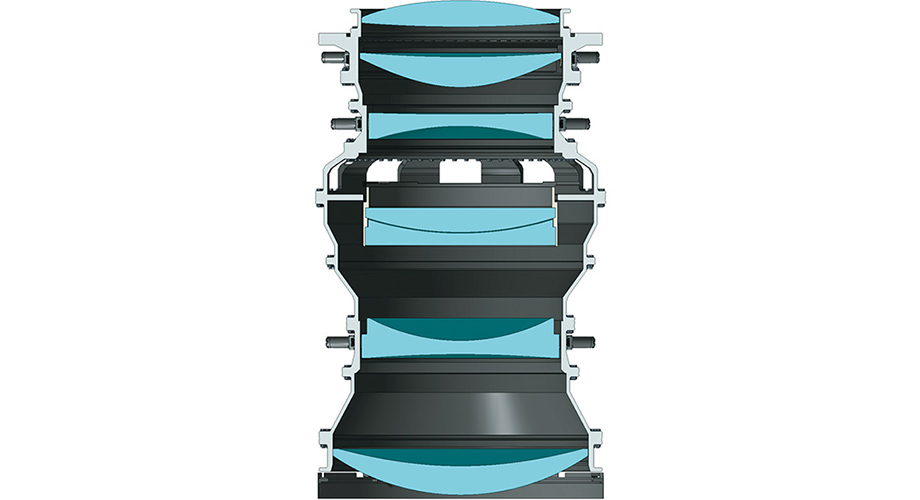

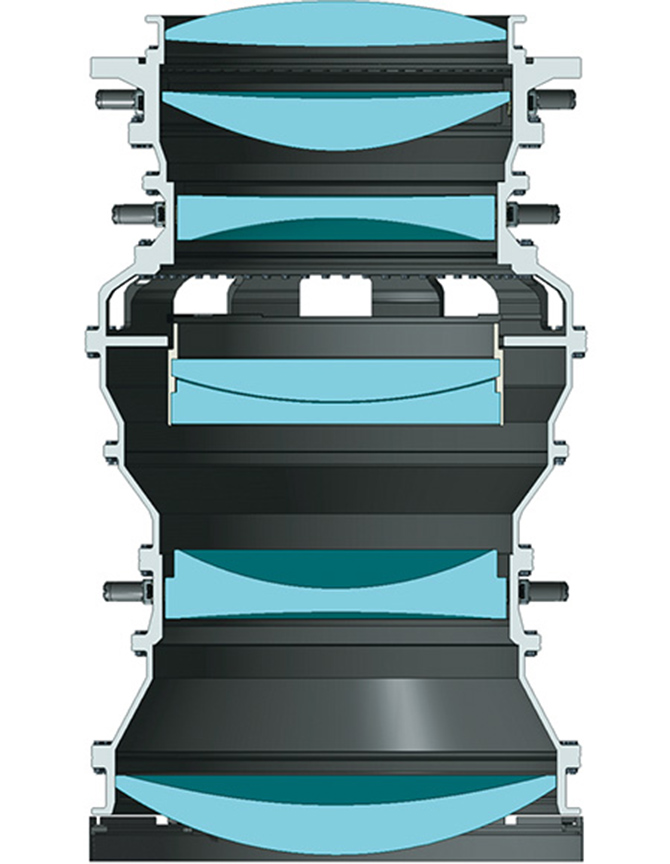

The Lens Barrel Design Used in the Prime-Focus Corrector for the Hyper Suprime-Cam

If the SC's corrector was expanded in diameter by three times then, theoretically, the field of view should also increase three fold. In practice, however, this approach would not satisfy the two rigid constraints imposed on the HSC for installation in the existing Subaru Telescope: a prime-focus corrector that weighs no more than 900 kg and has an external diameter measuring no larger than 1,000 mm.

Various proprietary Canon technologies helped to overcome the challenges faced during the development of the HSC. For the lens system, Canon employed aspherical lens elements, which are more difficult to manufacture as their diameter increases, helping to reduce the number of lenses used and minimize the total weight without compromising resolving power. Compared with the SC, the lens's aperture was increased by about 1.6 times (effective diameter of 820 mm) while realizing a three-fold increase in the field of view.

An ideal optical design bears fruit when the device is realized as planned. Canon improved its proprietary contact-type free-form measurement machine (A-Ruler) in order to measure the aspherical surface of a lens with greater accuracy. In addition, the company developed a stitching method to measure the lens profile on a segment-by-segment basis and precisely join together the measurement data of each segment. This method enables the overall shape of a large lens measuring over one meter in diameter to be measured with nanometer-level precision without changing the conventional segment area for measurement. Canon's technological know-how, accumulated over many years of developing optical systems for semiconductor lithography equipment, made possible the high-precision processing of large aspherical lenses. By bringing together advanced technologies, Canon has overcome the technological challenges faced when manufacturing large-size aspherical lenses.

Key Canon Technologies Installed Approximately 4,200 Meters above Sea Level

#Social contribution#Space#Physics#Chemistry

Prime-Focus Corrector Incorporated in the HSC

The prime-focus corrector for the HSC also makes use of several other technologies and technological know-how. Atmospheric dispersion correction (ADC) enables the high-precision correction of the dispersion of light as it passes through the earth's atmosphere,3 while wide spectral range anti-reflective coating (W-ARC) increases light transmittance and minimizes ghosting to help the HSC consistently realize high resolution over the whole observation area.

To reduce the total weight of the corrector, Canon had to substantially reduce the weight of the lens barrel supporting the highly accurate lens elements. Material selection has been of critical importance since the start of the project. For the HSC's corrector, Canon selected a highly rigid, lightweight ceramic material with a coefficient of thermal expansion nearly the same as that of the quartz used in some of the lenses. Even in subtropical Hawaii, temperatures on a mountain summit located approximately 4,200 meters above sea level can sometimes drop below zero degrees Celsius. When two different raw materials are used in combination, both materials are usually subjected to stress when changes in temperature cause them to expand and contract. The similarity between the thermal expansion coefficients of the quartz and ceramic in the HSC system almost completely nullifies this stress. For the lenses in the system, which were made using optical glass materials, Canon developed a lens-centering mechanism called S-Lec (Subaru LEns Centering mechanism) to keep the lenses consistently positioned at the center of the optical axis. This is another technology contributing to the superior imaging performance of the HSC's corrector.

- 3 Atmospheric dispersion

A blurring of stellar images caused by differences in refractive indexes between wavelengths of stellar light due to the dispersion of stellar light passing through the atmosphere.

Canon Continues to Take on Challenges Towards the Realization of a Next-Generation Ultra-Large Diameter Telescope

#Social contribution#Space#Mechanical engineering#Physics

Test observations using the HSC ultra-wide-field prime-focus camera installed in the Subaru Telescope began in August 2012. And we may not have long to wait before the Subaru Telescope identifies the true nature of dark matter and dark energy, shedding light on the vexing mystery of what the universe is.

The next challenge for Canon is already underway. This time, Canon is taking part in the construction of the TMT (Thirty Meter Telescope), an ultra-large telescope 30 meters in diameter. The TMT is a joint project by scientists in Japan, the U.S.A., Canada, China and India, slated for completion by 2027.

The primary mirror of the TMT is to be constructed from an array of 492 segment mirrors, each with a 1.44 m diameter. 82 spare mirrors are also required, for a total of 574 mirrors. Of these, Canon is in charge of 175 mirrors and has already started mass-producing them.

Canon is pressing ahead with technological innovations to meet the growing expectations of the astronomical observation field for high-level optical technology, measurement technology and precision machining technology.