History

The history of Canon's intellectual properties in the printing field

Printing

-

1965Canon files a patent application for its proprietary electrophotography technology

In 1962, an American-born plain-paper copier was launched in Japan. The copier used the xerography system developed by Xerox Corporation, which had acquired more than 600 patents, including peripheral technologies that were not used in the product. In order to enter the copier business, it was necessary to develop a product without infringing on Xerox's patents. Canon developed a new electrophotographic method, the NP system, that differed from Xerox's xerography method. The first patent application for the NP system was filed in 1965. Many more patent applications related to the NP system were filed, and rights were obtained. Then, in 1970, Canon launched the NP-1100, a plain-paper copier based on Canon's proprietary NP system.

Canon's first copier: NP-1100 -

Late 1960sBlade cleaner patent licensed to many copier manufacturers

Canon obtained many patents in the development of the NP system, but one of the most revolutionary was an invention for cleaning the photoreceptor surface. The xerography method used selenium photoreceptors, which were delicate at the time, so a cleaner made from rabbit fur was used. On the other hand, the NP system used CdS, which is tougher than selenium, as the photoreceptor, and covered it with an insulator, which enabled the use of a hard rubber blade cleaner. This made it possible to clean without residual toner. Canon received many inquiries about this blade cleaner, and we later licensed our blade cleaner-related patent to many copier manufacturers.

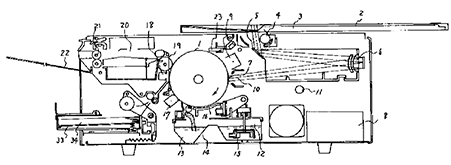

Patent drawings related to the blade cleaner -

1979Launch of a copier capable of printing clear images on plain paper

In the 1970s, copiers were large and expensive, so copier manufacturers around the world were working to develop monocomponent development copiers with the aim of making them smaller. However, they couldn't solve the problem of not being able to print clearly on plain paper. In this situation, in 1979 Canon launched the NP-200J, the world's first plain-paper copier equipped with the jumping development method (dry type). The jumping development method was a new method in which a developer using insulating toner is put into a non-contact state with a photosensitive drum on which an electrostatic latent image is formed, and an image is formed by making the insulating toner fly onto the electrostatic latent image. Adopting the jumping development method simplified the configuration of a copier, and realized an overwhelmingly small size and low price. It has been very popular all over the world. A patent related to this technology was selected as a Highlight Invention for fiscal 1979 by the Science and Technology Agency. This was a key technology used in subsequent copiers and laser printers, and contributed to the expansion of Canon's copier business.

Plain-paper copier: NP-200J (launched in 1979) -

1982Launch of a personal copier with an integrated cartridge

Until the 1970s, copiers were used exclusively in offices for business applications because they required regular maintenance. In 1979, Canon began development of copiers for home use. By developing the revolutionary change in thinking and technology of the "all-in-one toner cartridge system," in which major components such as the toner and drum are replaced together, Canon was able to perfect a maintenance-free copier. In 1982, Canon launched the PC-10 (nicknamed a "mini-copier" in Japan), a personal copier equipped with this cartridge. Its small size, user-replaceable toner cartridges, and lack of regular maintenance dramatically transformed the production, sales, and aftermarket of electrophotography products. As many as 470 patents were incorporated in the all-in-one toner cartridge around the drum alone. The patented technologies in this cartridge were used not only in personal copiers, but also in laser printers.

Personal copier: PC-10 (launched in 1982) -

1985Launch of the world's first thermal inkjet printer

In the mid-1970s, Canon researchers were focused on the broad potential of inkjet technology, and continued this research and development day after day. One day, during an experiment, a heated soldering iron accidentally touched the needle of a syringe filled with ink, and ink droplets spurted vigorously from the tip of the needle. This serendipitous event led to a series of various experiments and verifications, ultimately resulting in the birth of Canon's unique inkjet technology for emitting ink droplets with heating from a heater. In 1977, Canon filed a basic patent for the world's first thermal inkjet (Bubble Jet) technology, laying the foundation for subsequent inkjet printers. This method was named the Bubble Jet (BJ) method, and the first BJ printer product, the BJ-80, was launched in 1985. Canon has actively applied for many patents since the filing of the basic patent for Bubble Jet technology in 1977. One of our basic inventions, Patent No. 01396884, received the Imperial Invention Prize, the highest award of the National Commendation for Invention, in 1994.

How a soldering iron and syringe triggered a key invention

BJ-80 (launched in 1985) -

1990Development of a new fixing technology that reduces power consumption

In 1990, Canon developed a new proprietary technology: the on-demand fixing system. The on-demand fixing system is a structure in which a thin fixing film and a ceramic heater come into contact with each other. The toner on the recording paper is sandwiched between the nip formed by the fixing film and a pressure roller, and the ceramic heater applies heat to the toner via the fixing film to fix the image. This mechanism makes it possible to make copies without warm-up time, which realizes a significant reduction in standby power consumption. Canon received a Vanguard Energy Conservation Award for equipment using this fixing system. Moreover, this fixing system is also used in today's laser printers.

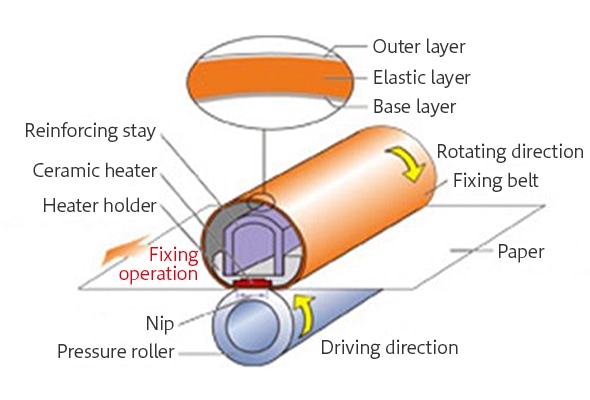

Diagram of the current on-demand fixing system -

1992Launch of the world's first full-color copier equipped with technology to prevent counterfeiting of banknotes and securities

Canon was the first company in the world to practically implement anti-counterfeiting technology for banknotes and securities, and in 1992 we launched a full-color copier (Color Laser Copier 550/350) equipped with this technology. This anti-counterfeiting technology had been under investigation since 1988, and consists of two technologies: a counterfeit tracking system and a banknote recognition system. The counterfeit tracking system can identify the machine used to make a copy by attaching an invisible code to the copy. The banknote recognition system stores feature data about banknotes in advance in a device, and prevents counterfeiting by outputting blacked-out data when an attempt is made to copy a banknote. Canon filed many patent applications relating to anti-counterfeiting technology in the late 1980s, ahead of our competitors. In response to requests from other companies, we licensed this anti-counterfeiting technology to other companies in the same industry on a fair and non-discriminatory basis.

-

1999Launch of a thin flatbed scanner

The thin flatbed scanner Canon launched in 1999 was designed to be slim and sharp, using the image of a Japanese sword for its shape in profile. It realized a new concept of stylish flatbed scanners meant for home use, as distinct from the rugged products up to that time, which had focused on functionality. This product received the Good Design Award in 1999, and was selected as a JIDA Design Museum Selection by the current Japan Industrial Design Association in 2001. It received the Japan Institute of Invention and Innovation Chairman's Prize (Design Registration No. 1077104) at the fiscal 2002 National Commendation for Invention.

CanoScan FB636U (launched in 1999) -

2003Launch of MEAP-equipped MFPs that support adding customized applications

Conventional multifunction printers (MFPs) are complicated to operate due to their wide range of functions, and there was a problem in that it was difficult to customize them to suit the user's workflow. Canon developed MEAP (Multifunctional Embedded Application Platform) to solve this problem. MEAP is an application platform for Canon MFPs that uses a common software infrastructure of application programming interfaces (APIs) corresponding to the functions of MFPs. The platform was groundbreaking in allowing development vendors to deploy their own applications on it. This allows users to select applications to suit their workflows and customize the functions of their MFPs. Canon has received a patent for MEAP's underlying technology that allows multiple MEAP applications to call a function group equivalent to the MEAP platform.

Intellectual Property History

by business field

-

Printing

The history of Canon's intellectual properties in the printing field

Read more

-

Medical

The history of Canon's intellectual properties in the medical field

Read more

-

Imaging

The history of Canon's intellectual properties in the imaging field

Read more

-

Industrial

The history of Canon's intellectual properties in the industrial field

Read more