Technology in ProductsContinuous Feed Printers

Canon’s Continuous Feed Digital Printers Offer High Quality, High Speed and High Productivity

Continuous feed printers are used in commercial printing to create high quality catalogs, forms, posters, fliers, direct mail and more. Canon's continuous feed printers can print on various media, including coated paper originally designed for use in offset printing, achieving image quality and productivity that rival conventional methods.

March 17, 2022

How Commercial Printers Work

A variety of printing methods are used by commercial printers, but they can broadly be divided into conventional offset printing and the newcomer, inkjet printing. Offset printing uses exposure and developing processes to turn aluminum sheets into printing plates. These printing plates, which utilize the mutually repellent nature of oil and water to create sections of plate to which ink adheres and sections that repel ink, are then used to perform printing. Once a plate is created, it can be used repeatedly for printing, enabling large amounts of printed materials to be created in a short amount of time and at little cost.

However, color printing requires four colors of printing plates to be created—cyan, magenta, yellow, and black. This results in a high unit cost when using offset printing for short print runs.

Inkjet printers employ minute nozzles to directly spray ink onto paper. Because they do not require printing plates, they can easily handle variable print jobs that use the same designs and formats but involve minor changes to printed data, such as mailing addresses.

Read More

Canon's Commercial Printer Technologies

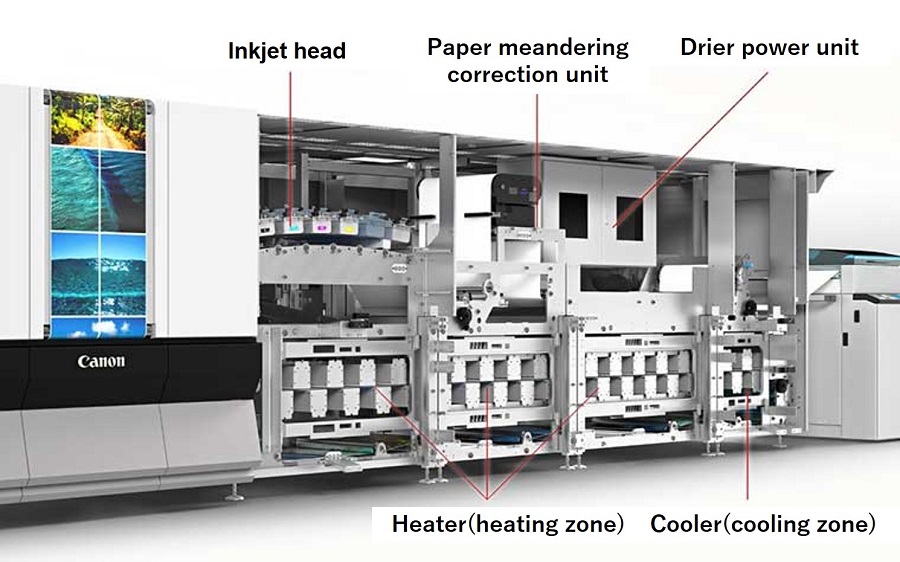

Canon's ProStream continuous feed printer is a commercial printer with a twin engine that combines a device for printing on the top surface of roll paper with a device that prints on its rear surface. Canon has developed their own unique pigment ink and base coating that enables high-quality printing on coated paper designed for use with offset printing, something which has thus far been difficult with conventional inkjet printers. The ProStream was carefully designed, including its drying mechanism, to perform high-resolution printing on all kinds of paper.

Ink Set Technology

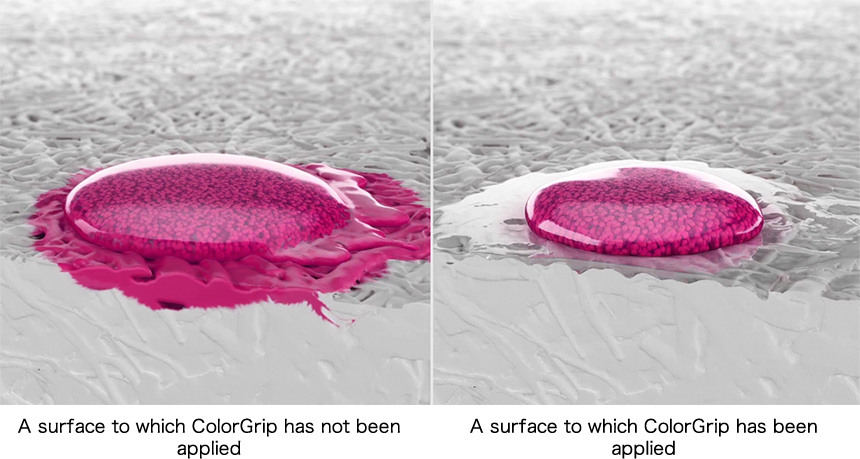

ProStream employs the ink set technologies of Canon’s proprietary ColorGrip base coating and highly concentrated polymer pigment ink in order to solve a major problem faced by conventional inkjet printers; ink being repelled by coated paper for use in offset printing.

ColorGrip is applied to the surface of the paper before the color ink used for printing. This provides a smooth surface of the paper without altering its texture, so that ink droplets can be accurately placed and pigment particles can be quickly fixed. On paper with rough surfaces, such as premium grade paper, book paper and comic book paper, ColorGrip stops much of the ink's pigment at the surface of the paper, helping prevent the ink from soaking into the paper or bleeding. On smooth paper such as coated paper, the paper itself resists ink absorption, making it prone to neighboring ink droplets mixing into each other. ColorGrip helps keep this from occurring, thereby preventing image blurring.

helping prevent the ink from bleeding into the paper

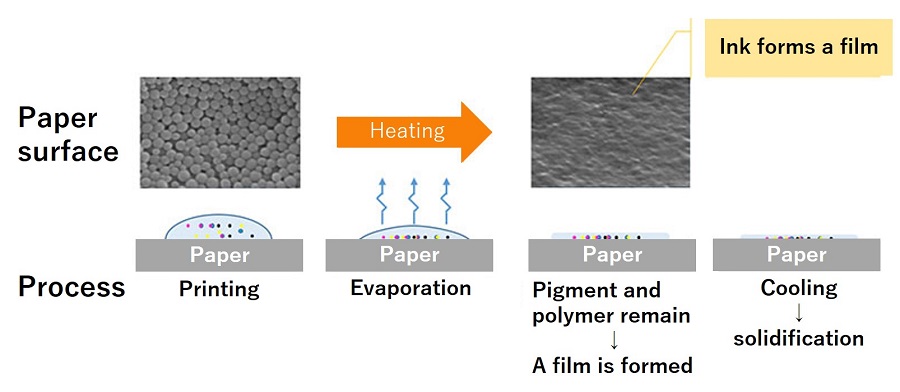

For the polymer pigment ink, ink pigment is contained within a polymer, and it turns into a gel upon contact with ColorGrip. This keeps ink droplets from mixing with neighboring ink droplets, soaking into the paper, or bleeding, and improves their placement accuracy. During the heating portion of the drying process, much of the pigment and polymer remain on the surface of the paper, and with further heating they form a film that clings tightly to the paper. This keeps as much pigment on the surface as possible and enables high density printing on various types of paper.

Forming a strong film through heating and cooling

Non-contact Drying Using Air Flotation

Canon's unique “air flotation non-contract drying technology” involves blowing heated air over both sides of the paper to make the paper roll float. Because drying is accomplished without direct contact with the paper, the process avoids placing stress on or damaging the paper. Real-time automatic control is used to constantly supply the dryer with the optimal amount of energy. This helps avoid wasting energy and maintains a consistent, high level of quality.

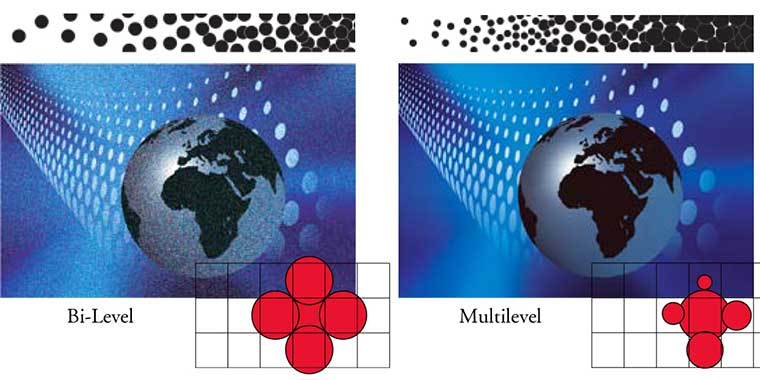

DigiDot Technology

The newest ProStream print heads can handle a high resolution of 1,200dpi and are equipped with DigiDot technology, a multilevel printing technology that enables print heads to eject 2 or 4.6-picoliter ink droplets from the print head depending on the images to be printed. Changing the size of the ink droplets makes it possible to create clear details and achieve smooth, natural gradations while efficiently controlling ink consumption.

Inline Quality Control

In high-speed printing, quality control is crucial. Many companies perform quality management by hand, and are thus more prone to errors. Canon has developed a unique, automatic quality management technology based on a high-speed camera system. This Inline Quality Control (IQC) technology optimizes print quality by automatically adjusting printers based on the properties of the kind of paper being used. It also constantly monitors each individual nozzle, from start to finish, to confirm that there are no printing defects in the printed material.

PreFire Simulation

PreFire technology refreshes the ink within the print head whenever it is not being ejected. This eliminates the need for ink discharge and reduces head operation and helps save ink usage. It enables consistent droplet sizes and placement. It is also effective at preventing nozzle clogging.

HeadSafe

When large amounts of time pass between ink ejections, the ink can dry or become more viscous, leading to nozzle clogging. To prevent this, Canon has equipped printers with HeadSafe, which places caps filled with water below the heads of colors (CMY) that are not being used, keeping the heads from drying and protecting them from becoming clogged with dust. This technology helps ensure that print heads are in optimal condition and can easily and rapidly switch between full-color mode and monochrome mode.

Paper Feed

Canon has developed paper feed technology that can handle a wide variety of papers, from thin to thick types. Multiple paper feed rollers are controlled precisely by sensors to maintain a constant paper tension. Steering frames that perform the adjustment of paper edge in lateral direction minimize paper meandering and maintain a high level of printing accuracy.

SPA MP Controller

ProStream includes a data processing system controller called a Scalable Raster Architecture (SRA) MP, designed by Canon for high volume print environments, and an innovative PDF workflow. It converts page description language (PDL) data such as IPDS, PCL, and PDF data into high-resolution raster images (images made up of countless dots) in real time. This enables uninterrupted, high-speed printing even by ProStream systems that operate two printers simultaneously.

Operators can use the intuitive user interface to leverage the full performance of the printers. With the optional PDF DFE (PRISMAcontrol), they can also directly send PDF files to printers and manage production.

PRISMA Software

Canon's PRISMAcontrol workflow management system is a one-stop solution for individual print systems that enables workflows with PDF processing and job management functions. Operators can perform gang-run printing (imposing multiple different types of print data on a single paper sheet) for roll paper printing jobs, as well as changing printing order, to flexibly respond to rapidly changing printing environments.

PRISMAproduction is an advanced digital printing workflow management system that offers both high productivity and flexibility for commercial printing and form printing. It centralizes and precisely controls digital print material production, improving the competitiveness of printed material production.

The software is modular, so configuration and setting changes can be performed easily. Optional modules can be added as necessary, so this workflow system can meet new needs without changing the overall feel of operation, expanding as business grows, all while keeping initial costs low. PRISMAproduction also boasts an exceptionally designed GUI that printing operators can use to smoothly configure and operate printing systems, reducing the time required for everything from preparing materials to final output. Standardized jobs can be completely automated, preventing human error and improving the reliability of entire printing systems.