Detecting Cracks with AI Technology

Canon is currently developing an AI technology capable of detecting cracks and other defects, which will enhance the efficiency of inspection work related to the maintenance and management of social infrastructure (bridges, tunnels, etc).

December 5, 2019 Featured Technology

A Global Infrastructure Crisis

An enormous bridge crumbling in just a few seconds… These kinds of unbelievably tragic accidents have shocked the world. In fact, there is only one reason why a sturdy structure such as a concrete building could suddenly collapse: wear and tear. It is said that concrete generally starts deteriorating after about 40 to 50 years. For this reason, overlooking signs of wear can result in severe accidents, which is why the inspection and repair of concrete structures is crucial for safeguarding our way of life.

The Growing Demand for Imaging-Based Detection

Cracks are one of the important criteria used for diagnosing the deterioration of concrete structures. Typically, a civil engineer with specialized knowledge would inspect such structures by checking for cracks visually, sketching the results of the inspection and then preparing inspection data based on their findings. An inspection method like this is not only very time-consuming and costly—as it requires manual recording of as many as several hundred thousand cracks one by one—but it also cannot accurately represent the length and shape of the cracks. To tackle the issue, in recent years, the industry has increasingly looked toward using cameras to conduct image-based inspection.

The conventional method of close-up visual examination

Highly Precise and Efficient Detection of Cracks with AI

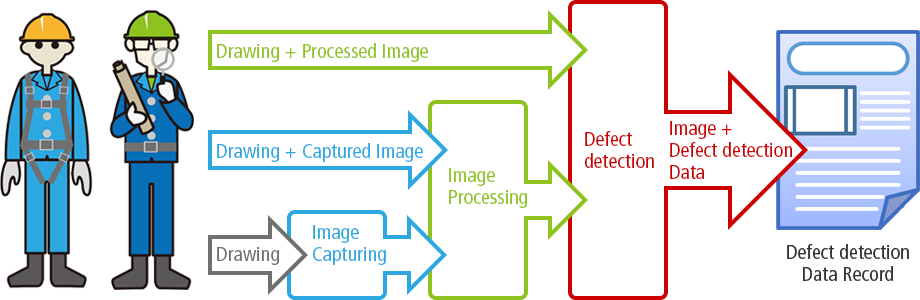

As a leading manufacturer in the field of imaging, Canon is applying the image-related AI technologies it has cultivated over the years to develop technology capable of detecting cracks in concrete structures. The image-based inspection system that Canon is developing comprises three processes:

1. Image capture

2. Image processing

3. Defect detection

Each process helps to enhance the precision and work efficiency of inspections.

1. Image capture

This first process leverages Canon’s wealth of expertise as a camera manufacturer, using Canon’s full-frame DSLR cameras and drones to capture high-resolution images of the objects to be inspected. Cracks as fine as 0.2mm wide can be identified using the captured images.

Images are captured using a Canon DSLR camera and a drone

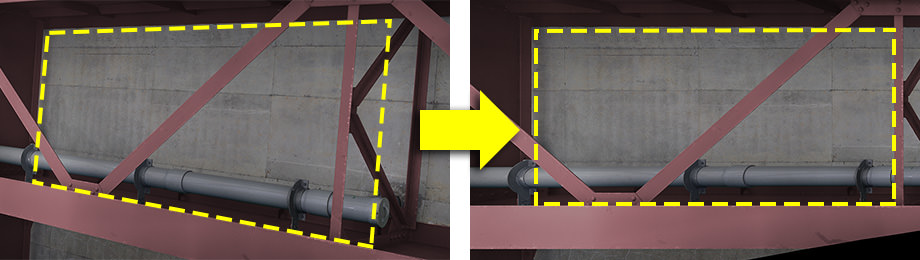

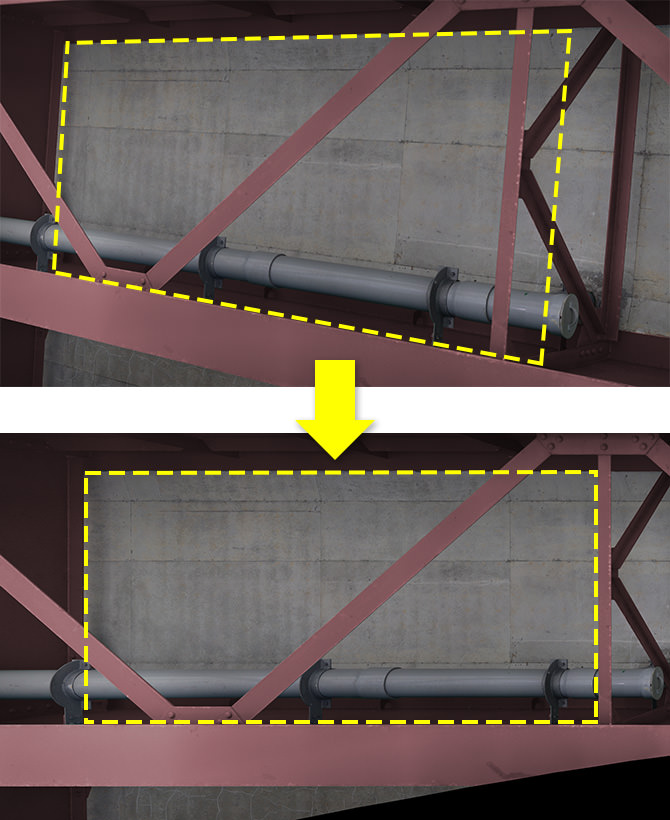

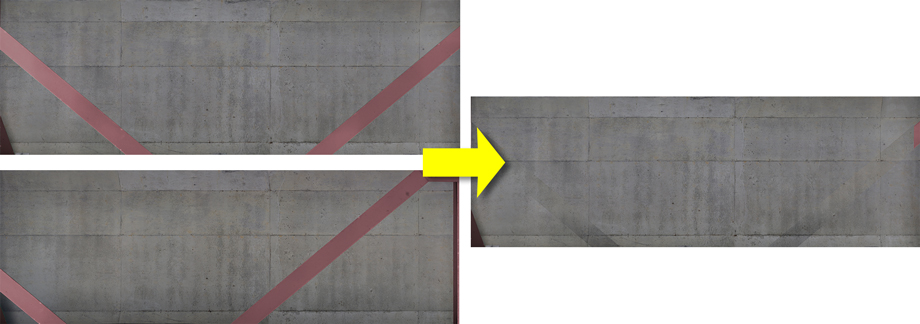

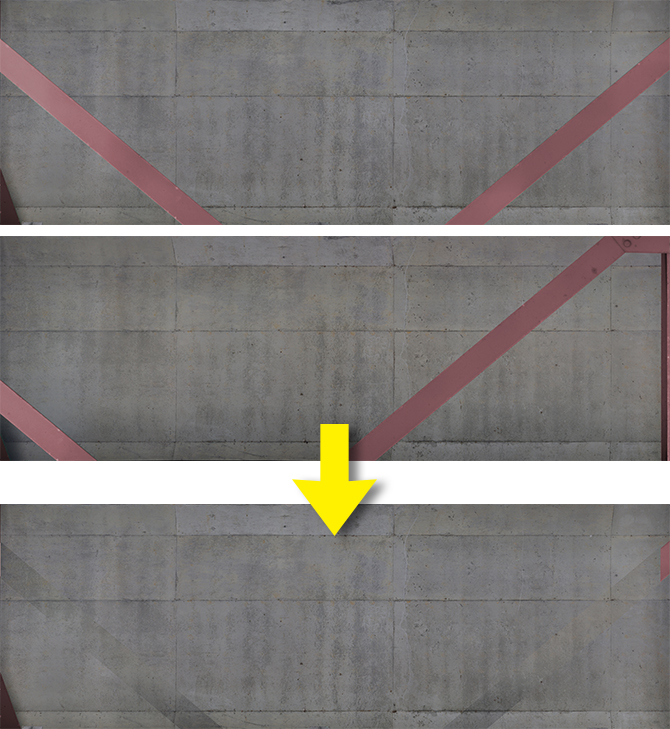

2. Image Processing

In this phase, tilt correction is performed to correct the angle of the captured image so as to obtain a front-facing view of the structure. The camera image is then precisely overlaid onto the drawing of the structure to enable accurate evaluation of cracks. Pillars and other objects obstructing the wall can be removed from the final image by merging multiples images captured from different angles.

Tilt correction

Removal of obstructions

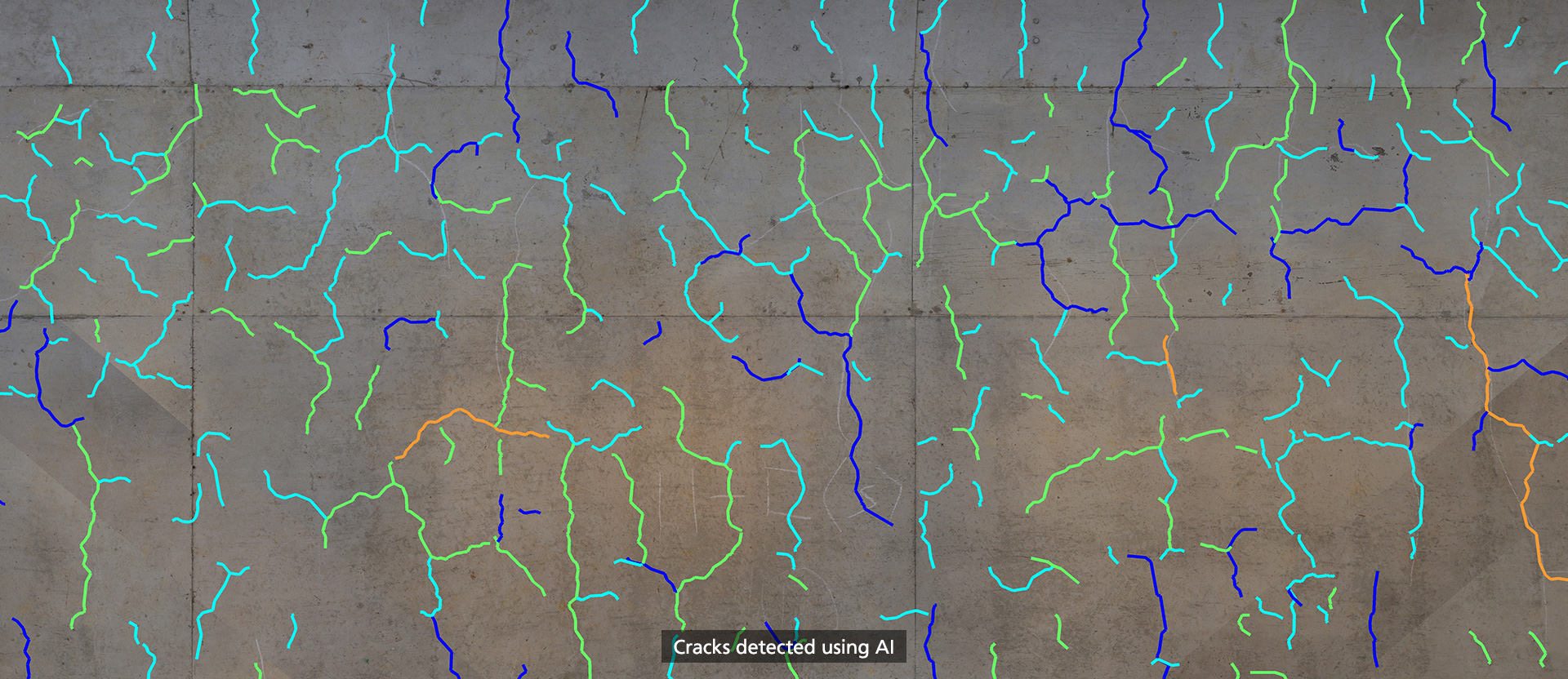

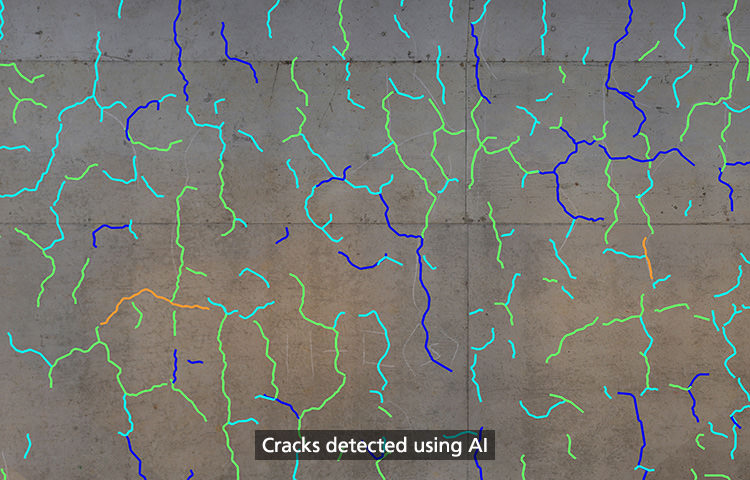

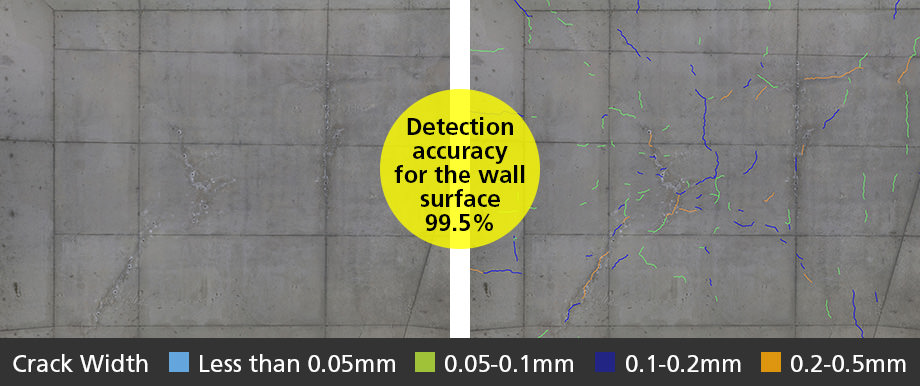

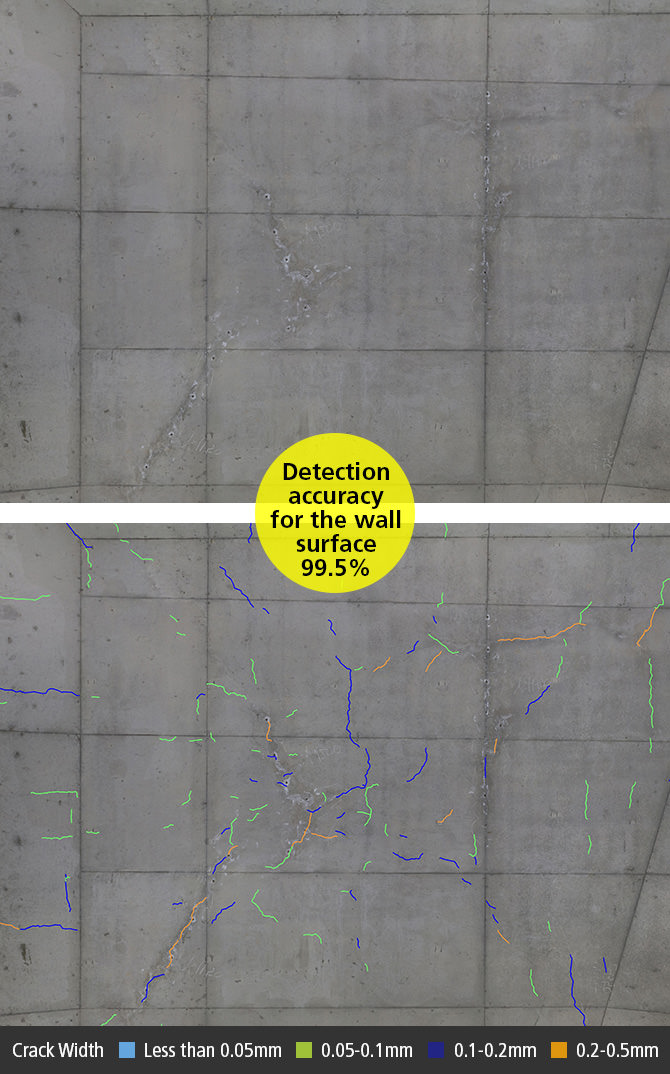

3. Defect Detection

This process utilizes AI to detect cracks and measure their width. Canon’s system is trained to recognize wall surface cracks using deep learning, enabling it to accurately identify cracks without erroneously detecting dirt or joints. As illustrated in the example below, the system demonstrates a high level of detection precision with an accuracy of 99.5%*.

- *Detection rate is based on actual results of demonstration experiments conducted by Canon.

Crack detection results

In addition, to address the needs of civil engineers to correctly record the area of each crack, the system can also automatically process and “join” cracks detected in segments.

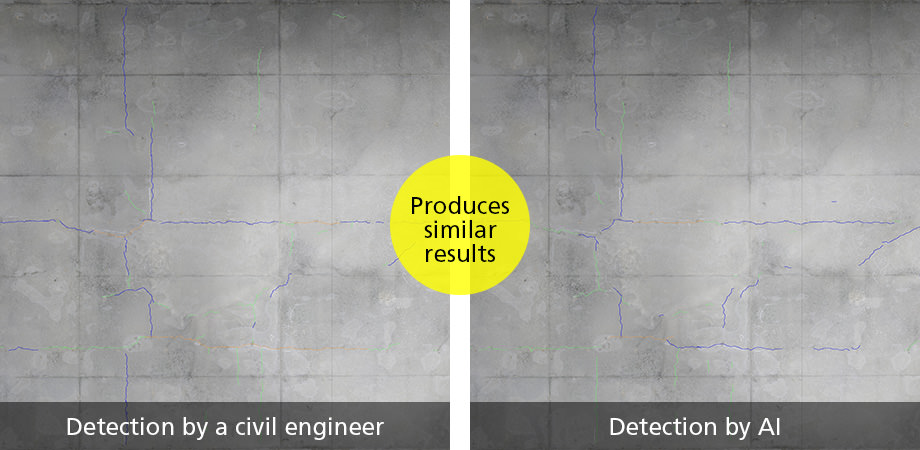

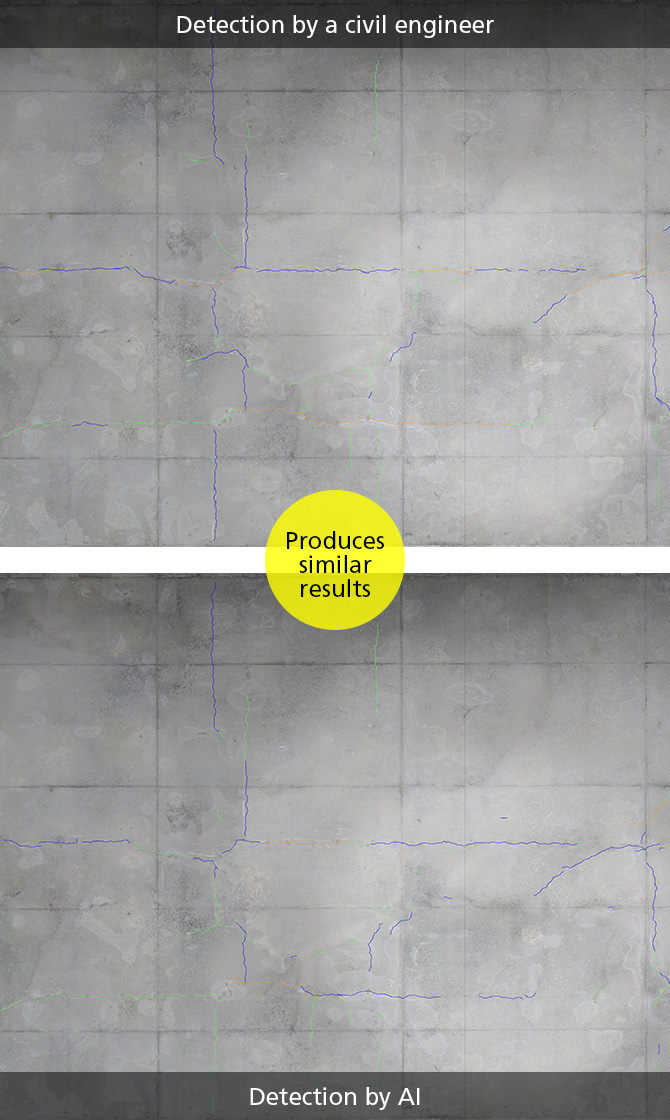

These image processing technologies are capable of producing results that compare favorably with those obtained by civil engineers manually identifying cracks from images.

Comparison of Detection Accuracy

Civil engineers can generate highly accurate inspection data simply by checking the detection results output by Canon’s new defect detection AI system. This helps to significantly reduce the number of man-hours. In one case, a civil engineer needed 720 minutes to identify about 500 cracks from the images and prepare the corresponding inspection data, whereas the defect detection AI system allowed the civil engineer to only take 90 minutes completing the process in one-eighth of the time. Yet another noticeable advantage of the AI system is the consistency it offers in the quality of the results, which tends to vary in the case of manual detection.

Joint Research with Experts in Infrastructure Inspection

When developing the defect detection AI system, it was necessary for the system to learn from data that correctly indicated the position of a crack. However, unfamiliar with the field, Canon developers lacked a basic understanding of the nature of these cracks. To that end, joint research was conducted with Tosetsu Civil Engineering Consultant Inc., who have a wealth of experience image-based inspection. This collaboration led to the development of a defect detection AI system suitable for such practical applications as merging defect detection results.

Canon’s Image-based Infrastructure Inspection System (3:40)

*In order to view videos, it is necessary to consent to the use of cookies by our website. If the videos are not displayed, please click the "Cookie Settings" and accept cookies.

Meeting Society’s Expectations with AI and Imaging Technology

In the future, we will see a rapid increase in the proportion of infrastructure that is over 50 years old. In Japan, bridges that were constructed 50 years ago or more (with a length of at least 2m) accounted for about 25% of the total number as of March 2018. That number will grow to approximately 39% by 2023 and to about 63% by 2033. In order to maintain the safety of infrastructure that is anticipated to collectively deteriorate, there are high expectations that an image-based infrastructure inspection system could enhance work efficiency. Furthermore, managing images and inspection results in a digital format offers many other merits, including lower data management costs and the ability to detect issues earlier.

Addressing society’s needs, Canon’s image-based infrastructure inspection technology will continue to evolve.