Image-based Infrastructure Inspection Using AI

Technology That Helps Keep Expressways Safe

Expressways are an integral part of social infrastructure. In Japan, they comprise a large number of bridges, tunnels, and other concrete structures, and Canon’s AI-backed image-based infrastructure inspection service has just started operations in their maintenance.

The expressway network facilitates the daily flow of people and goods, and is a mainstay of the economy and industry. Inspections, therefore, are indispensable for ensuring its safe, secure and comfortable use.

Canon’s image-based infrastructure inspection service is poised to play a crucial role in checking the bridges, tunnels, and other concrete structures on the expressways.

March 7, 2022

Ensuring safety through maintenance and inspection of concrete structures

As Japan is surrounded by the sea with numerous mountains and rivers, its expressways have many more bridges and tunnels compared with those of other countries. The expressway network covers a total length of approximately 9,600 kilometers* and contains around 16,700 concrete bridges and 1,680 tunnels. Most of them were constructed from around the 1960s, and about 50% of the total number have been in service for more than 30 years. To ensure that they can be used safely, inspection and repair works must be carried out without oversights.

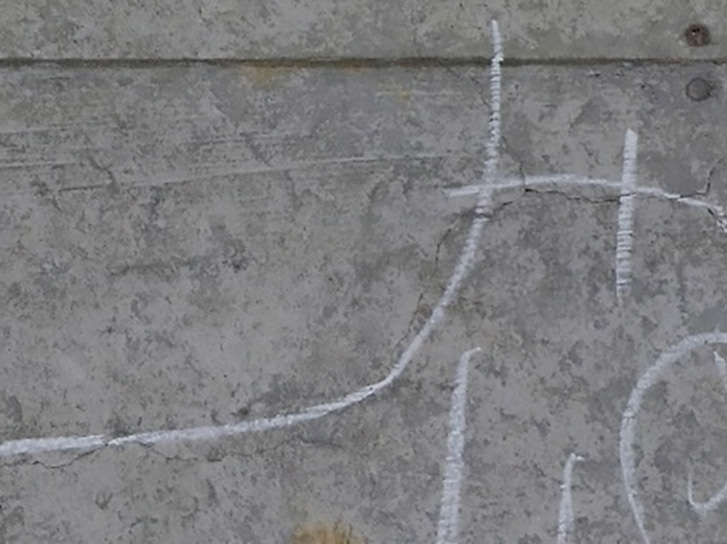

Cracks are one of the criteria used for diagnosing the soundness of concrete structures. These structures, even old ones, can be structurally sound if there are very few cracks, while new ones may not be so if many cracks are found. The length and width of the cracks as well as where they are located also determine the overall impact on the structure, hence, comprehensive evaluation by an inspection engineer is required.

With new construction projects and road-widening works taking place on the expressways of Japan, structures that require inspection will continue to increase. Currently, there are a sufficient number of inspection engineers to maintain the safety of the expressways. However, Japan’s declining birthrate and aging population means that it may face a shortage of such engineers in the future. Not only so, there are also differences in the inspection skills and decision making of individual engineers that need to be attended to. To ensure that structural soundness can be analyzed appropriately, there is a growing need to make use of digital technology to quantify the degree of defect and enable more advanced and efficient diagnosis.

- *Total length of expressways managed and operated by the three NEXCO companies: East Nippon Expressway Company Limited (NEXCO East), Central Nippon Expressway Company Limited (NEXCO Central) and West Nippon Expressway Company Limited (NEXCO West)

Nippon Expressway Research Institute Company Limited (NEXCO RI)

Masakazu Honda, Division Chief, Maintenance Management and Promotion Division, Infrastructure Development Department

NEXCO RI

Precise defect detection, close to that of skilled inspection engineers

Nippon Expressway Research Institute Company Limited (NEXCO RI) provides high-level and efficient research, studies, technological development and support to the three NEXCO companies that construct, manage and operate the expressway network in Japan.

In the past, the mainstream approach for inspection works involved the engineer visually checking the structure and drawing a sketch of the detected defect. However, in recent years, image-based inspection, which uses photographs taken at the inspection site, is increasingly being adopted. While advancements in image resolution have allowed fine cracks to be identified, they have also led inspection engineers to spend significantly more time at the desk checking images.

It was against this backdrop that NEXCO RI conducted research and studies aimed at developing more advanced and efficient inspection techniques, and what caught their attention was Canon’s “Inspection EYE for Infrastructure” image-based infrastructure inspection service, which utilizes deep learning (Artificial intelligence, AI). Masakazu Honda, Division Chief of the Maintenance Management and Promotion Division, Infrastructure Development Department at NEXCO RI, describes Canon’s AI system as follows.

“It offers a very high level of detection accuracy. An example is the continuity of cracks. While some AI systems detect individual cracks in a piecemeal fashion, Canon’s AI system offers a level of precision that is close to visual checks by inspection engineers, such as detecting successive cracks as one single crack. Not only that, Canon’s AI system might also be capable of detecting peeling, efflorescence*, rebar exposure and other such defects.”

The “Inspection EYE for Infrastructure” defect detection AI system was developed through a joint study between Tosetsu Civil Engineering Consultant Inc., a pioneer in the field of image-based infrastructure inspection in Japan, and Canon. By using images of defects traced by Tosetsu Civil Engineering Consultant’s engineers as training image data, the deep learning AI has learned to detect cracks at a level comparable to that of highly skilled inspection engineers. The system’s high level of precision has been well acclaimed, and the system is now under trial runs in different parts of Japan with the intention of an eventual full-scale deployment.

- * Efflorescence is the formation of white deposits on concrete and other types of surfaces.

A high-resolution Canon EOS DSLR camera is used for capturing the inspection images. It is mounted onto a motorized panoramic camera mount that automatically pans and tilts to record multiple images within the inspection range. These images are then stitched together during post-processing to create a high-definition image for the AI system to detect defects.

Image of chalk marks drawn by the engineer during visual checks

Result of automatic crack detection using AI

With the AI-based “Inspection EYE for Infrastructure” defect detection system, cracks found by an engineer were accurately traced by the system just like the engineer. Precision is further enhanced by using AI models optimized for specific target structures, such as bridges and tunnels.

More sophisticated inspections help to enhance safety and nurture engineers

“Automated defect detection using AI is only a part of the inspection process, and an engineer will have to make the final evaluation. Corrections will be needed if the AI system’s evaluation is deemed inaccurate after the engineer checks the results, and if there are many changes to be made, work hours are unlikely to be shortened,” says Honda. The condition of the infrastructure and inspection criteria may vary for each customer, so the performance of the AI system for the “Inspection EYE for Infrastructure” is adjusted according to the quality of the customers’ inspection images. For expressways, adjustments are made based on the actual inspection data provided by the three NEXCO companies, and the system has delivered a high level of precision.

By reducing the time needed for checking images, the “Inspection EYE for Infrastructure” helps to free up more time for engineers to visit the actual sites. In other words, it also potentially contributes to engineer training. Stressing the importance of on-site experience, Honda says, “We also learned a lot at the inspection site answering to our seniors who asked us to explain why a particular damage had occurred. To mature as an engineer they need to see the site with their own eyes and think about why things are the way they are. Even with [AI providing] greater convenience, it remains vital [for engineers] to develop the ability to evaluate via on-site observations.”

Offering safety and security through AI technology: Technology that grows with the customer

Efforts to employ Canon’s image-based infrastructure inspection service in the inspection of expressways have just begun. In reality, the image-based approach currently accounts for about 20% of the total inspection works, and AI defect detection is used in only a small portion of these.

Canon will continue its efforts to contribute to safety and security by further enhancing the level of precision while carefully considering the conditions of each customer as we work hand in hand in our development journey.

Inspection EYE for Infrastructure

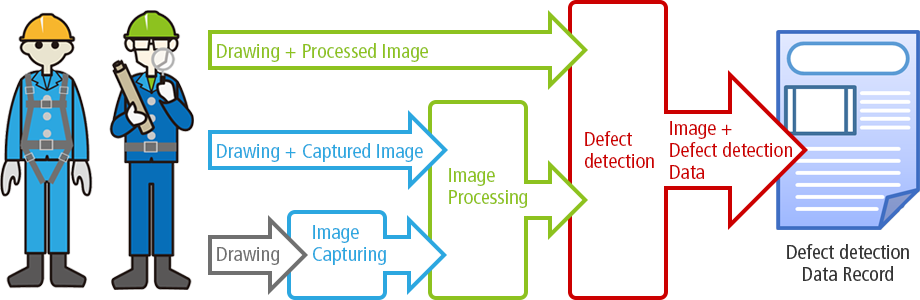

The “Inspection EYE for Infrastructure” comprises three different services – image capturing, image processing and defect detection. Through learning from actual inspection images, defect detection using AI is capable of delivering a level of performance comparable to that of highly skilled inspection engineers, such as determining whether cracks of different widths are part of a continuous crack or otherwise.

Image processing and defect detection are also available as standalone services.