Controlling Molecules at the Nanometer-level to Achieve Bright, Vivid Colors

Inkjet Ink Technology

Digital printing technology continues to evolve to meet diversifying printing needs. Canon develops ink for its products in-house, as it is an important element that determines image quality to provide new value to customers by making vivid colors and a wide range of color expression possible.

October 16, 2023

Improved Image Quality with Pigment-based Ink Expands its Applications

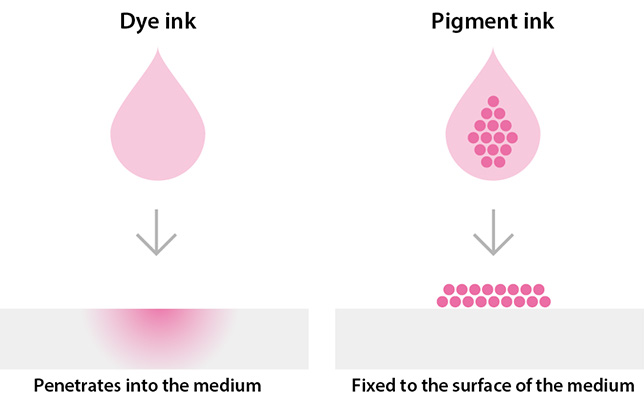

Inkjet technology is expanding its applications from home-use and small office printers to the field known as commercial printing, which includes printing of publications, direct mail, catalogs, and other items. Furthermore, it has also expanded into the field of industrial printing, which involves printing on a variety of media, such as labels and packages. There are two types of water-based ink used in inkjet printers: dye-based ink and pigment-based one. Printing at home is often done on water-absorbent paper such as plain paper or inkjet exclusive paper, and therefore primarily uses dye-based ink, of which colorant penetrates into the medium (paper) to show the color. In addition to conventional paper, commercial printing may also use coated paper that resists water And industrial printing may involve printing on plastic sheet, glass, metal, or other materials that do not absorb water either. Instead, pigment-based ink, of which colorant is fixed to the surface of the medium, is thus the mainstream in these fields.

Dye ink and pigment ink

Dye ink is advantageous in enhancing image quality due to its excellent gloss and color development, and pigment ink is excellent in fastness of printed matter due to its tough light resistance and water resistance. Based on this difference, the respective inks have been chosen for different purposes. Recently, however, pigment ink have evolved to achieve high image quality comparable to dye ink, thanks to improvements in pigment particle size and dispersion technology, and can now be used for printing applications involving photographs, such as posters.

In high-speed printing, ink must quickly settle on the paper and dry. Canon has enhanced the rub resistance of printings by changing the ink material so that text and images will not be damaged due to rubbing between sheets of high-speed printed paper when they overlap. It is also working to improve customer convenience by preventing clogging of inkjet printheads and enhancing ink functionality so that ink quality does not deteriorate even after long-term storage.

Nanometer-level Ink design Achieves Vivid Colors

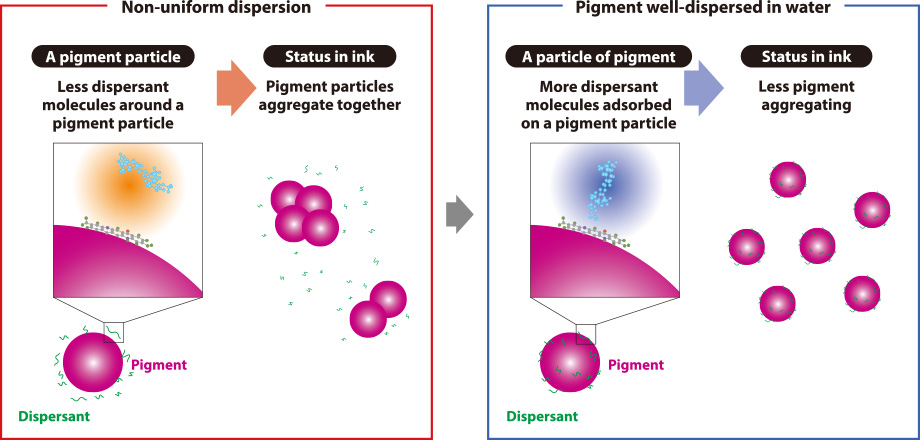

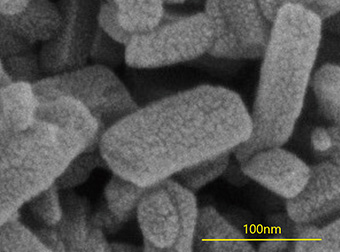

In ink, pigment is dispersed, instead of being dissolved, in water. If the pigment is not well dispersed in water, the pigment particles aggregate and precipitate. Aggregated particles can deteriorate image quality, such as poor coloration, and can also clog the nozzles of the inkjet printhead, making printing impossible. Also, smaller pigment particles generally achieve better colors with less pigment, and broader color gamut. High image quality requires to adequately control dispersion state of pigment using dispersant that prevents pigment particles from aggregating and to reduce the size of pigment particle to as small as about 100 nm*.

* nm: nanometer = One-billionth of a meter. 100nm is about one-thousandth the thickness of a hair.

Controlling dispersal state using dispersant that helps disperse the pigment

Canon apply advanced simulation technologies to identify ideal molecular structure of materials for coloration and dispersion. Canon designs the ink, develops the production technology necessary to produce the ink as designed, and mass-produces the ink at its own factory. By exercising all these processes in house, Canon is producing highly functional pigment inks. This allows Canon to quickly provide high-quality ink to customers while reducing the effort from design to mass production to approximately one-third of the conventional method.

Accelerating high-quality ink development with computer simulation

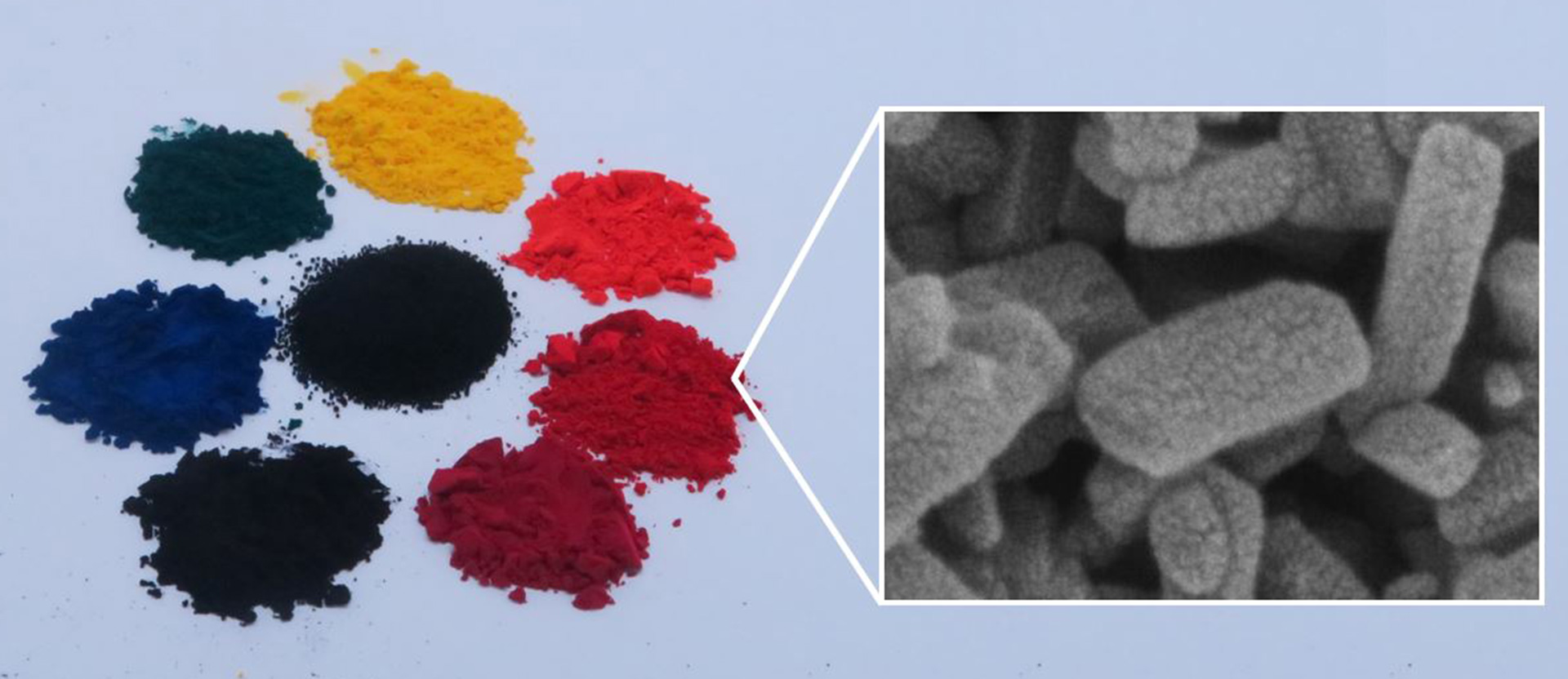

Pigment crystal structure given by computer simulation

Electron microscopic image of pigment crystals

Range of Expressible Colors Expanded by Newly Developed Ink

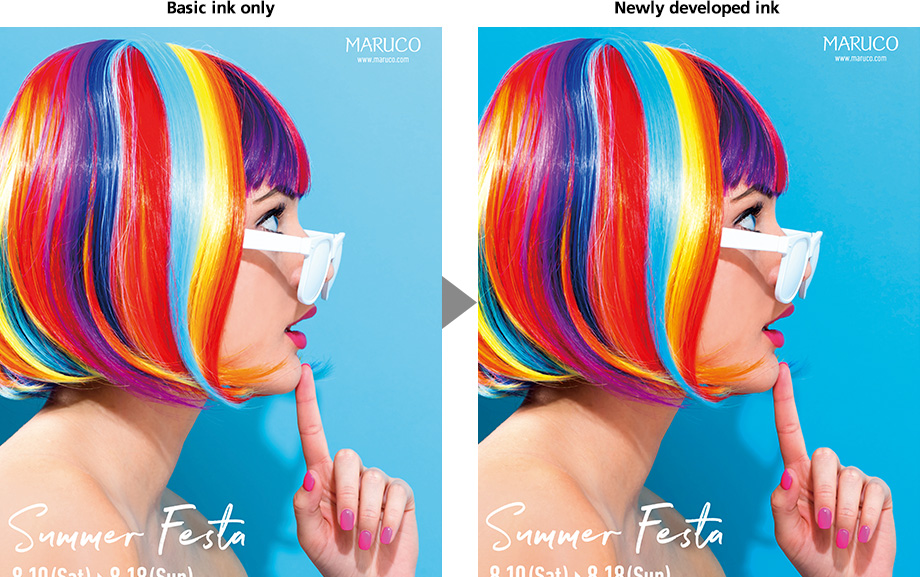

The needs for printed materials change with the times. Prior to new ink development, we research what colors are currently in demand. For example, posters require strong impression. To address this requirement, large-format printers are now equipped with fluorescent pink to express positive and light impression as well as bright, soft luminescence in orange.

These days, there is an increasing demand for the vivid color showcase composition with printed materials. Canon has expanded its color range for high brightness and high saturation with newly developed red, orange, green, and violet. The eye-catching coloration has been well-received.

High-impact bright color printing with newly developed inks

Improving Ink Technologies for Higher Image Quality

Canon is enhancing its lineup of printers to respond to diversifying digital printing needs. They include home-use printers for printing documents and photos, continuous feed printers for printing books and high-quality catalogs, large-format printers suitable for printing posters and drawings, and label printers that can print on labels and packages of various textures. By taking advantages of digital printing, which can be handled by a small number of people or those unfamiliar with the process, Canon strives to contribute to solving some social issues, such as labor shortages and lack of business successors in the printing industry.