Canon, Always a Stickler for Color, Is Now Focusing on Reproducing the Colors That People Perceive

Super Color Management Technology

Color is extremely important for those people who are involved in creative tasks such as designing advertisements and making posters. The gamut of colors that can be presented is expanding, thanks to the increasingly high definitions available through the devices used for input and output, such as the cameras that take photos and the displays and printers that output images. More than ever, solutions are being called for that take advantage of this change to produce colors that are faithful to the creator’s intent.

October 16, 2023

Color Management: Unifying the Colors across Different Devices

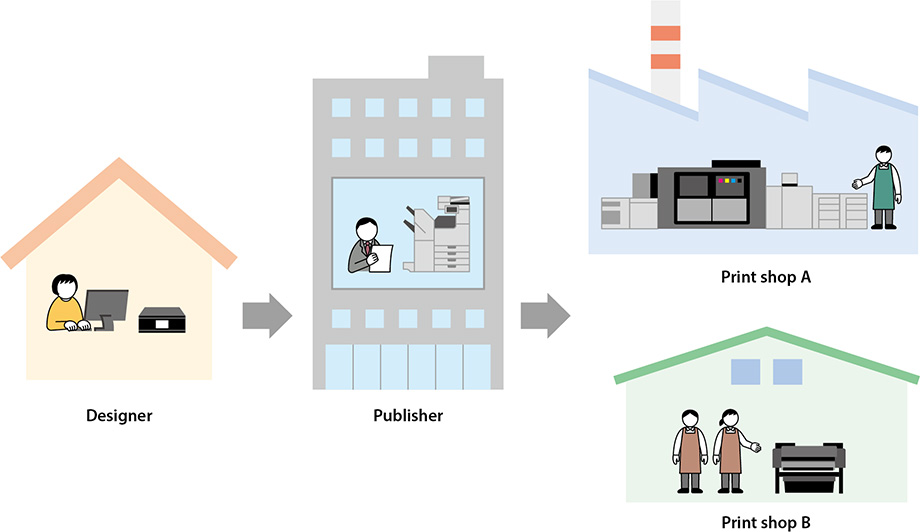

Technological innovations have brought about various changes in society. The field of printing is one such example. A shift is underway from conventional offset printing, which uses a printing plate, to digital printing, where digital data are printed directly onto paper.

With displays and printers, the respective colors that the devices can show are determined based on their models and specifications. To print an image containing colors that exceed the color gamut of a printer, the data to be printed must be converted to fit them to the color gamut of the printer. Color management technology plays an important role in digital printing in securing uniformity of colors among different devices by adjusting the data to be printed prior to being transferred to printing devices. Various technologies have already been developed for that purpose.

Color management technology plays an important role in securing unified colors among different devices

Diversification of Printed Matter Makes Color Matching All the More Important

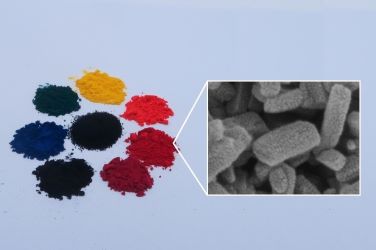

Digital printing devices generally use one of two main methods. One is the electrophotography used by copier machines where toner is fixed onto paper, and the other is the inkjet used in many home printers. Furthermore, the media or objects to be printed on are diversifying. Once they were mainly paper, but now they include labels, plastic sheets, and package boxes.

Conventional color management has focused on minimizing the difference of machine-measured color values of the printed image from different printers. Specifically, an image was printed under different conditions such as the printer model and media type, and then the printed images were measured with colorimeter, with the goal of getting the values as close to one another as possible. However, as the environment surrounding printing diversifies in terms of printing processes such as inkjet or electrophotography, paper characteristics such as matte or glossy, and print media materials such as cloth, sticker sheets, and label print sheets, people involved have come to realize that even if the colorimeter gives the same value, the colors may appear as different colors to the naked eye.

Diversifying Applications of Digital Printing

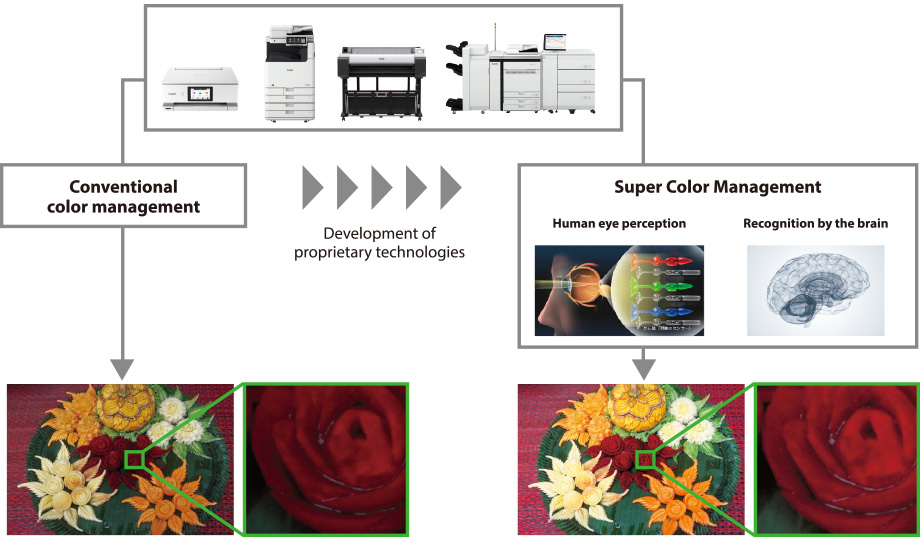

Conventional color management, which attempts to unify colors based on machine-measured values, evolved into Super Color Management (SCM), which unifies colors in terms of perception of the human eye.

Through development of cameras, displays and printers, Canon has spent many years doing research into colors. Canon has not only built its own proprietary color space data that can be applied to printing devices along with ink and toner color design simulations to lay a foundation to be shared throughout the company, but has further sophisticated the color space by adding another dimension of human color perceptions. With this technological foundation, Canon was able to come up with a “color equalization formula” to make colors of multiple objects look the same with human eyes.

Enabling Automatic Output of “Colors That People Perceive”

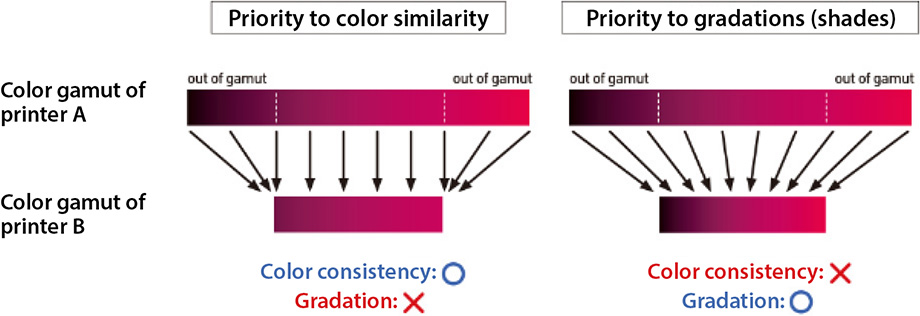

With conventional color management, sometimes the printed results look unnatural to human eye, because the original range of colors in the to-be-printed image is squeezed into the color gamut of the printer.

Canon is striving to reproduce colors perceived by the human eye by developing Super Color Management (SCM) that can appropriately process colors even when there is a big difference in the color gamut between the to-be-printed image and the printer that prints it.

Conventional color management usually employs either a color matching method (emphasis on color) or a gradation method (emphasis on color shading)

It has been found as a human visual characteristic that when a human looks at a print, the color he perceives differs from the color that corresponds to the color values of the print measured by the colorimeter for lightness, saturation, and hue (Differences in color tones such as red, green, and blue).

With SCM, Canon has developed a mapping process technology that takes these sorts of characteristics into account. Based on a proprietary algorithm, it assigns colors so that the human eye's impression of the printed image is closer to the original colors of the image to be printed, even if the color gamut of the image to be printed exceeds the range of colors that the printer can represent. It accomplishes this even when the color gamut of the image the user wants to print goes beyond the limits of the colors that the printer can produce.

Because the color gamut of images used for printing greatly varies, Canon has also introduced dynamic processing technology that determines the color assignment by comparing the color gamut of each image with the color gamut of the printer used, rather than statically assigning a uniform color assignment method to all images. This dynamic mapping process provides an effect that allows the impression to human eyes of printed material to be seen closest to the original color to be printed.

Assigned automatically to “colors humans perceive”

Conventional color management

It performs uniform mapping processing on all kinds of images. In some cases, the human eye feels the expression is flat with less shading than the original color.

Super Color Management

It automatically compares the colors that the printer can express with the colors of the image data to be printed, and converts the colors outside of the printer’s gamut into colors that are close to the original colors when viewed by human eyes.

Changing Corporate Marketing Workflow for Improved Productivity

With the spread of digital printing presses, there is a growing trend of printing original goods within companies and using them for marketing activities. In such a case, it is common to print posters on a large-format printer, flyers on an office multifunction printer, shop cards on a small inkjet printer, and so on, using different printers depending on the intended use of the printed material. In cases where the output paper and printer models are different, or where the output has to be checked at multiple sites, how to unify the colors has been a problem.

With the introduction of SCM, however, there is no need to spend time and effort to check the quality of print repeatedly. Even if no one has specialized skills, printing of original goods that require matching colors can be made in-house, changing the workflow of corporate marketing.