Expanding Our Line of Compact Commercial Digital Presses with Diverse Media Compatibility

Inkjet Technology for Commercial Printing

In the field of commercial printing, there is a demand for high-speed, high-quality commercial digital presses that have a small footprint and can print on a variety of paper stock. Canon has developed compact commercial digital presses with excellent print media compatibility by combining three technologies—ink circulating print head, high-concentration latex ink, and the closed heater process.

October 16, 2023

Compact Commercial Digital Presses with High Productivity Demanded by the Market

Analog offset printing is suitable for high-volume printing and was once the mainstay for commercial printing presses producing catalogs and other printed materials. In recent years, however, the industry has been transitioning to digital printing, such as variable printing in which contents change from one printed piece to the next, and on-demand printing, suitable for high-variety small-lot production. High-quality commercial digital presses, which are comparable to offset printing, have also emerged.

Digital commercial printing can be divided into two main types—electrophotographic printing, in which toner is fixed to paper, such as in copiers, and inkjet printing, which jets ink droplets from fine nozzles. Electrophotographic commercial digital presses have the advantage of being compact and low-cost to install, but they do not easily print materials larger than A3+ size(329×483mm)or print at high speeds. Although inkjet commercial digital presses are fast and can produce results comparable to offset printing for such items as photo books and product catalogs, the equipment tends to be larger and more expensive.

As customers’ needs diversify and the demand for digital printing increases, the market is looking for presses that are superior to offset printing. That demand can be fulfilled by Canon’s high-speed, high-quality digital presses that are compact and can handle everything from thin to rough paper.

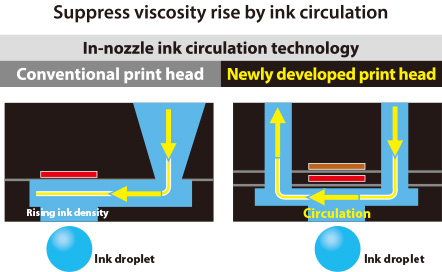

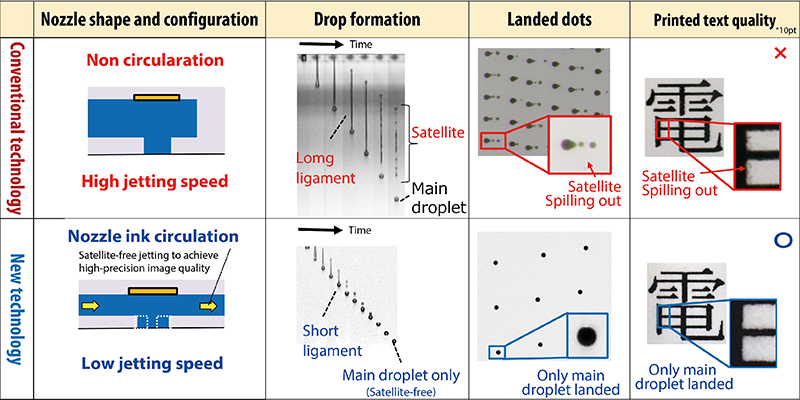

A New Concept in Print Heads—Ink Circulation

Canon has developed print heads compatible with high-concentration latex ink*1 to prevent nozzle clogging and keep stable droplets jetting. An inkjet print head fires ink from fine nozzles, but moisture tends to evaporate from the nozzles when exposed to the air, causing ink viscosity to increase. This thickening of the ink is especially pronounced with high-concentration latex inks, which make print heads more prone to jetting failures. To prevent ink viscosity from rising, we placed tiny ink flow channels on both sides of the heater so that the ink does not build up in one spot—rather it stays fresh as it circulates through the nozzle area. Since the viscosity of the circulating ink keeps low, the jetting velocity can be reduced to the point where the main droplet of ink fired is a few pico litters*2 in size. Thus, only clean droplets form without “satellites*3,” resulting in further enhanced image quality. In the development of this print head technology, proprietary simulation technologies that support Canon’s businesses were used to the fullest, including simulations of the ink concentration distribution inside nozzles in ink circulation and the behavior of ink droplets affected by jetting velocity.

- *1 Polymer particles dispersed in water

- *2 pico litter = billionths of a milliliter

- *3 Small stray droplets that form in addition to the main droplet during ordinary jetting.

They adhere in unintended spots, marring image quality.

Suppress viscosity rise by ink circulation

Satellite-free jetting to achieve high-precision image quality

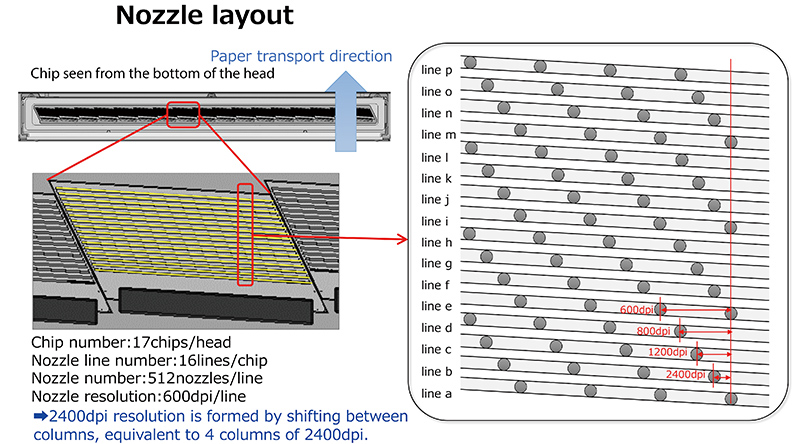

Our newly developed high-speed, high-resolution, long print heads for commercial and industrial printing contains a high-density array of nozzles. The total number of nozzles per color is well over 100,000, approximately 100 times more than the approximately one thousand nozzles in home printer heads. By slightly shifting the lines of 600 dpi nozzles (600 dots per inch) and arranging them in 16 parallel lines, we achieve an equivalent of 2,400 dpi with four lines (or 1,200 dpi with eight lines). For high-quality printing, there are usually just one or two lines at 1,200 dpi, but we have employed high-precision, high-density chip fabrication and mounting technologies cultivated by Canon’s long history to succeed in developing a print head with high-density nozzles at more than four times that density.

High-density inkjet nozzle array

High durability is required for commercial digital presses, which are used primarily by printing companies, in order to avoid malfunctioning and downtime that can have a significant impact on operations. The gap between the nozzles of a print head and the paper being printed on is only about 1mm. This means that if a corner of the paper becomes slightly curled, it can touch the head. Sometimes, the surface layer of commercial printing paper will contain hard particles such as calcium carbonate for glossiness, which can damage the nozzles and cause misprinting. That is why Canon uses a faceguard—a hard metal plate only a few tenths of a millimeter thick—to protect every nozzle section. This plate ensures the toughness of the print head so that customers can use our presses free of concern.

Achieved Miniaturization by Developing a New Heater That Significantly Improved the Fixing Processes

Pigment inks — used for inkjet printing—generally do not penetrate the fibers of printing paper. Rather, the ink stays on the surface. This has the merit of producing clear text and vibrant colors. It is also more water-resistant and longer lasting than dye inks. However, the pigment on the surface can get rubbed off, so improved resistance to abrasion is essential for commercial printing, where high durability and high quality are vitally important.

To solve this problem, Canon has developed high-concentration latex ink consisting of pigments, latex, and various additives. By melting the latex in the ink, a film is formed that coats the pigment, thus enhancing the bonding, which in turn provides durable resistance to rubbing.

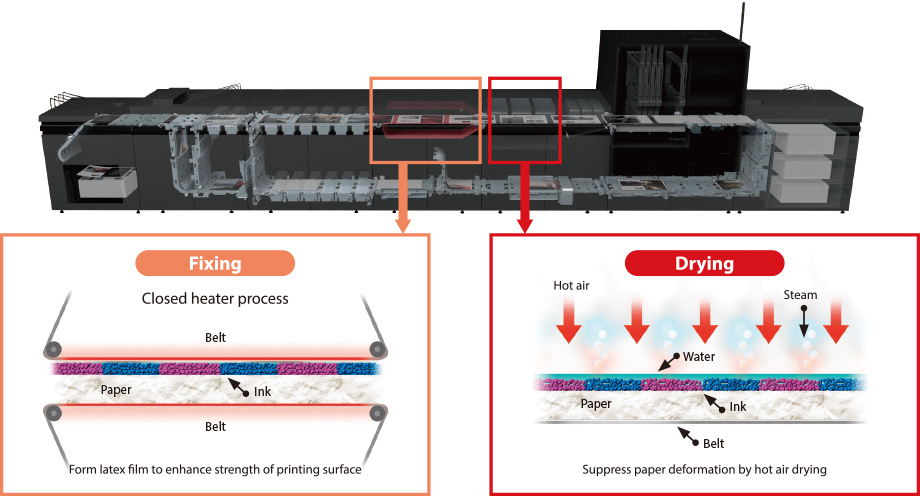

When fixing ink on paper, moisture is needed for anti-curl agents or other additives to penetrate the paper. But moisture will also cause paper to deform, so the ink must be dried quickly. For this reason, conventional inkjet commercial digital presses need to have a large drying equipment to instantly evaporate moisture upon printing. Then, once the paper deformation has been prevented, the paper is steamed in order to fix the ink. The need for these processes has resulted in commercial digital presses tending to be very large pieces of machinery.

The innovation that solved this problem of contradictory drying and moistening processes is Canon’s closed heater process, whose design is based on the fuser we developed for electrophotography, applying that know-how for the first time to an inkjet commercial printer. In the new closed-heater fixing system, the paper printed with high-concentration latex ink is semi-dried using non-contact hot-air impingement, with some moisture retained. It is then fed into the closed heater where the paper is heated in a sealed space, sandwiched between the upper and lower belts, with the remaining moisture helping the additives penetrate the paper. At the same time, the ink pigments are coated with a latex film, strengthening the bonding to the printed surface. This new design cuts out more than half the conventional transport distance from drying to fixing while eliminating the need for a large drying drum, thereby significantly reducing the size of the equipment.

Moreover, with high-concentration latex ink, less ink needs to be deposited, which means less moisture to cause paper deformation, making it possible to print on thin paper. In addition, because the ink can be jetted directly from the ink head onto the paper, printing on rough paper with concavities can be done reliably, allowing the use of a wide variety of paper types.

Closed heater process that makes equipment more compact

Continuing to Create New Printing Technologies by Combining Technologies

Our new printing technology is largely based on innovations in three technical areas—ink circulating print head, high-concentrate latex ink, and the closed heater process. Each of these derives from Canon’s expertise in two major digital printing domains built from the ground up—electrophotographic technology and inkjet technology.

For ink circulating print heads, we applied ink circulation technology developed for other products, and using our inkjet head production technologies, manufacturing methods, and mounting technologies, we have been able to produce a high-accuracy head that contains well over 100,000 nozzles. In developing high-concentration latex ink, we improved on the ink technology of Canon Production Printing (CPP)—a Canon group company that has long been involved with commercial digital presses—optimizing the composition of ink pigments and additives. The closed heater process is also based on a CPP design plan with design and control technologies incorporated from the electrophotographic product development department.

In this way, Canon incorporate some of our fundamental technologies in ink materials, devices, precision mechanisms, and image processing. These technologies give rise to products that are valuable to our customers and that only Canon can deliver.

We will continue to flexibly respond to the needs of the times by refining our various technologies.