Commercial Printing

Achieving unprecedented high image quality for a wide range of print media.

Digital printing enables a variety of output that can only be achieved digitally to meet diversifying commercial printing needs.

July 11, 2019Featured Technology

Meeting the Printing Industry’s Growing Need for Short-Run Production for a Broad Range of Applications

The need for short-run production for a broad range of applications is growing rapidly for commercially printed materials such as books, brochures, direct mail and catalogs. In direct mail, for example, the conventional practice was to send the exact same message to a large number of customers. Recently, however, digital marketing is utilizing data to customize printed messages according to each person’s interests, resulting in higher customer satisfaction.

Offset printing has thus far been a mainstay of commercial printing and is advantageous for printing high volumes of the same content. However, because it employs thin printing plates made of aluminum etched for printing, it is not cost-efficient for short-run production and does not easily handle individual print jobs.

Digital printing has risen to the fore to address such concerns. Since digital printing does not require printing plates, it is better suited to short-run production with quick turnaround time and variable printing that requires changes to the printed content for each sheet. Canon is meeting various needs in the digital printing market with high quality, productivity and reliability.

New Technologies Adopted to

Ensure High-Resolution 1200 dpi Printing

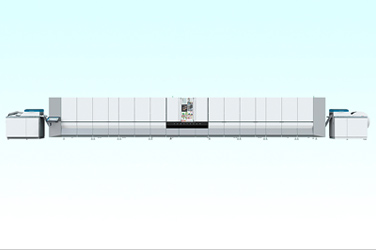

Canon and the Canon Group company Canon Production Printing(CPP)* have expanded their product lineups to provide optimal solutions tailored to customers’ objectives. One such product is the ProStream 1000, the company’s latest continuous feed press (for high-speed printing on roll paper) developed for the graphic arts market, where high image quality is required for high-quality catalogs, premium direct mail and other published materials.

This press features ColorGrip, a media-pretreatment applied before ink is printed onto media to prepare the paper surface and prevent the ink bleeding.

This technology enables the press to print on a wide range of media including conventional offset coated media which was considered difficult with prior technology. CPP’s proprietary polymer-based pigment ink (ink containing a polymer component that forms a durable film when heated and cured) enhances abrasion resistance and creates vibrant colors. It is also effective for accurate ink droplet positioning and detail sharpness, and together with the latest print head, the press supports high-resolution 1200 dpi printing, which is comparable to offset printing.

The air floatation non-contact drying technology, which dries the ink using an “air flotation” dryer system without the need for a paper conveyor belt, minimizes paper stress and produces high-quality printing on various media. CPP’s proprietary ColorGrip solution and air floatation non-contact drying technology produce high-quality output without compromising the paper’s texture.

*

Changed its name from Océ in 2020. This Netherlands-based company joined the Canon group in 2010 and accounts for a large share of the commercial production printer market.

The Diverse Technologies in Canon Printers

Canon also manufactures many other printers for commercial printing to meet a broad range of needs, including digital continuous feed presses and sheet-fed presses that print books, manuals and transactional application at high speed, and large-format inkjet printers for producing blueprints, posters, signages, etc.

Another of Canon’s strengths is in proprietary UVgel ink (gel-like UV-curable ink with excellent color gamut and environmental performance) that offers high image quality, high durability, productivity and support for a wide range of media. Canon also excels in such technologies as elevated printing that can even reproduce textures. Going forward, we will continue to deepen our group synergies and meet the world’s diversifying needs for digital printing.

CPP’s Elevated Printing Technology Recreates 3300-Year-Old Decorations from an Ancient Egyptian Pharaoh’s Tomb

The tomb of the 19th Dynasty pharaoh Seti I was discovered in the Valley of the Kings, where the ancient Egyptian rulers sleep. The tomb, considered the valley’s most grand, has been deteriorating since its discovery in 1817. To reconstruct this cultural heritage of ancient Egypt, in 2016, CPP partnered with an NPO, as part of the company’s social contribution activities, to use 3D photographic data taken inside the tomb to print large molds used to create life-size reconstructions of the tomb’s walls, pillars and sarcophagus. CPP’s unique elevated printing technology was able to print reliefs up to 15 mm thick by stacking layers of UV curable ink, faithfully reconstructing the tomb decoration.

Walls and pillars printed with the reconstructed reliefs

Relief reproduction using elevated printing technology