Materials Research

Material science drives the development of colorants, lenses and more; it is indispensable to product competitiveness.

Canon is creating new materials with unprecedented performance that will contribute to a sustainable world.

July 11, 2019Featured Technology

High-Color-Performance Xanthene-Based Dyes

Vivid Red that Doesn’t Fade

In most cases, since printer manufacturers do not develop original colorants in-house and instead procure commercially available dyes from suppliers, it is difficult for them to differentiate their colors from those of competitors. Canon, however, focused its development efforts on xanthene-based dyes, which boast superior coloration properties, to create a magenta dye capable of producing high-visibility reds. Although finding a practical application for xanthene dyes was considered difficult due to challenges related to robustness (light colorfastness), the Company’s research efforts paid off with the successful development of a new magenta dye that enables the printing of reds that are both vivid and robust.

Employing Proprietary Molecular Design in Search of Improved Robustness

#Chemistry

Canon began developing new dyes in the 1980s and has now amassed more than 10,000 types of dyes in its Canon Materials Bank. The bank represents a database of a diverse variety of technological know-how that, in addition to information on the synthetic and physical properties, includes data on the mechanisms behind the breakdown of dyes when exposed to such stimuli as external light and ozone gas. During the development of xanthene dyes, Canon introduced repeated simulations, molecular designs, synthesis, evaluations and analyses, arranging specific substituents in optimal locations to achieve both desired coloration performance and robustness. The result was the birth of new dyes.

It was 2012 when a proprietary dye was first used in the ink of the cartridge. A second-generation dye with further improved performance was later (2017) used in the ink cartridge, which contributed to improved print quality.

Moving from the Lab to Mass Production

#Chemistry

One challenge that needed to be addressed following the creation of xanthene-based dyes in the lab was mass production. Unlike the compact 300-milliliter reaction vessels used in laboratories, those used in mass production, with capacities exceeding one ton, are of an altogether different scale. For inkjet printers in particular, because ink ejection must be controlled at the picoliter level, even the slightest amount of impurities arising during synthesis could cause the ink nozzles in the print head to clog. Accordingly, R&D division and business group conducted joint research aiming at reducing impurities to less than one part per million. The collaborative efforts paved the way for commercialization by ensuring consistent ink quality during mass production.

Lead-Free Piezoelectrics

Developing Piezoelectrics with Low Environmental Impact

#Quality#Physics#Chemistry#Environmental awareness

Piezoelectric materials, which are essential for producing motors and sensors, have the ability to transform electrical energy into mechanical energy. Most piezoelectric materials, however, contain lead as a principal component, which has a negative impact on the environment, posing a challenge within the industry. In addition to continuing efforts to eliminate lead from lenses and solder, Canon is trying to eliminate lead from piezoelectric materials towards the goal of launching products that feature lead-free materials.

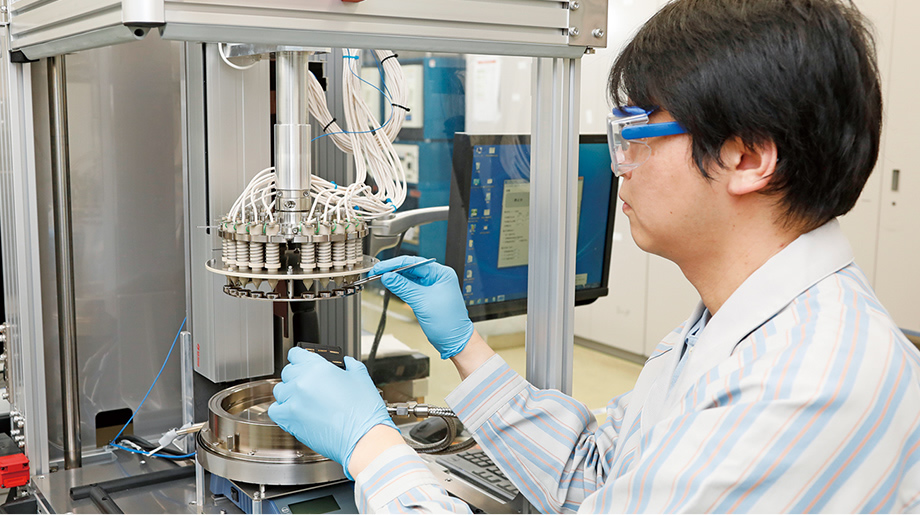

Preparing samples of lead-free piezoelectrics for analysis by sintering mixed raw particles