People love to capture snapshots of new scenery and sights and record all the discoveries and excitement on their journeys exactly as they see them.

However, turning an interesting subject into the perfect photo or video requires these photographers to first prepare and then carry around a number of lenses which, when combined, add up to a hefty weight.

With the emergence of mirrorless cameras, camera bodies became smaller and lighter in comparison to DSLR cameras. Then what about lenses? In response to that question, Canon has been releasing more and more compact, lighter interchangeable lenses that can be realized only through mirrorless mechanisms without comprising the image quality so highly valued by photographers.

Achieving a compact size without sacrificing image quality

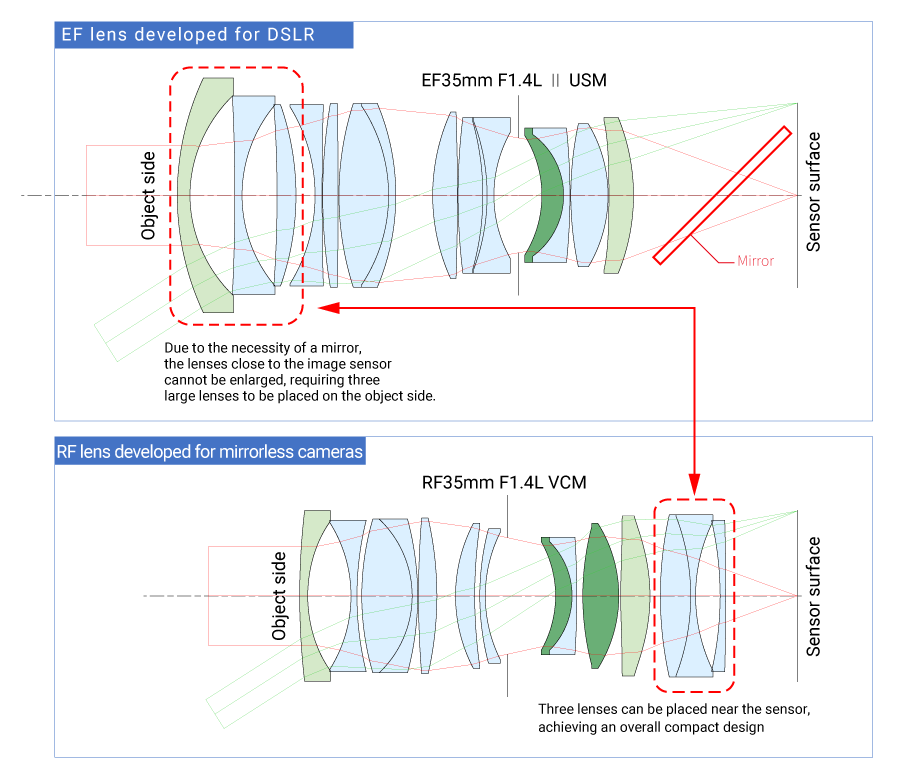

Because DSLR cameras require the installation of a mirror, they inevitably need a longer distance (back focus) between the interchangeable lens and the image sensor. In terms of optical design, this means that the lenses close to the image sensor cannot be enlarged; instead, the size of the object-side lenses must be increased.

In an interchangeable lens for a mirrorless camera, as a result of the structural characteristics of a short back focus due to the absence of a mirror, the assembly of lenses that were located near the object side in the DSLR’s interchangeable lens can be placed near the image sensor.

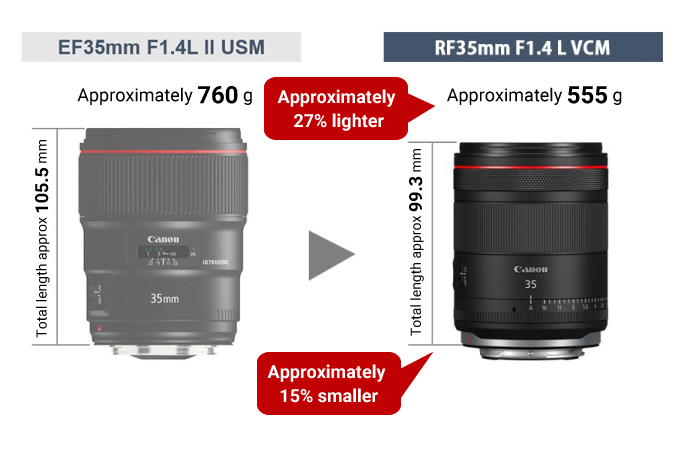

Additionally, Canon’s RF lenses employ a 54 mm diameter lens mount as large as that of a DSLR camera. This means that, for instance, in a 35 mm fixed focal length lens, the three large lenses that are located near the object side in a DSLR EF lens can be reversed and placed near the image sensor. As a result, enlargement of the object-side lens can be avoided, thereby creating an interchangeable lens with a compact design. When comparing the EF35mm F1.4 L II USM and the RF35mm F1.4 L VCM, we can see that the EF35mm F1.4 L II USM is more compact, with a total volume reduction of roughly 15%.

Volume and weight reduction through full-fledged simulation, while maintaining high quality

Interchangeable lenses, which are required to concentrate light on the image sensor with extreme accuracy, are delicate pieces of equipment so sensitive that the slightest change to the design or material could have an immediate impact on their performance.

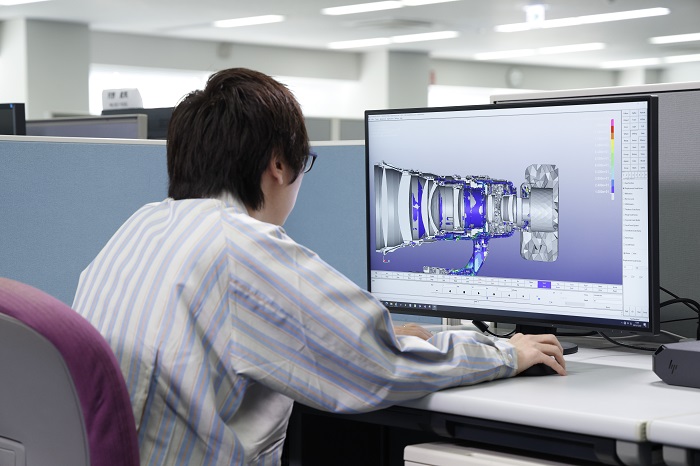

In conventional product development, to verify the appropriateness of the design on various intricately intertwined elements, such as the image quality, product durability, and weight balance in combination with a camera, numerous “prototypes” are physically constructed and undergo repeated tests and confirmation. However, at Canon, while seeking to improve image quality in lens design through optic design tools developed in-house, we independently established simulation technology that enables us to accurately predict the quality and performance of the lens in a virtual environment. This technology has made it possible to conduct thorough assessments and evaluations even under harsh test conditions that physical prototypes would not withstand for multiple tests and product high-quality lenses that can be used more reliably.

Even in the case of an effort to reevaluate the material of each individual part to make the lens lighter, we can use a simulation to find an alternative material that maintains high performance. For the RF35mm F1.4L VCM, in combination with the synergetic effect of size reduction, these efforts successfully reduced its weight by approximately 27% in comparison to the EF35mm F1.4L II USM.

We also actively incorporated automated assembly into interchangeable lens manufacturing, thereby achieving consistent high quality. The advancement of such production technology, with which lens are rapidly assembled with high precision, has also contributed greatly to quality improvements.

Eliminating weakness through accumulated technology

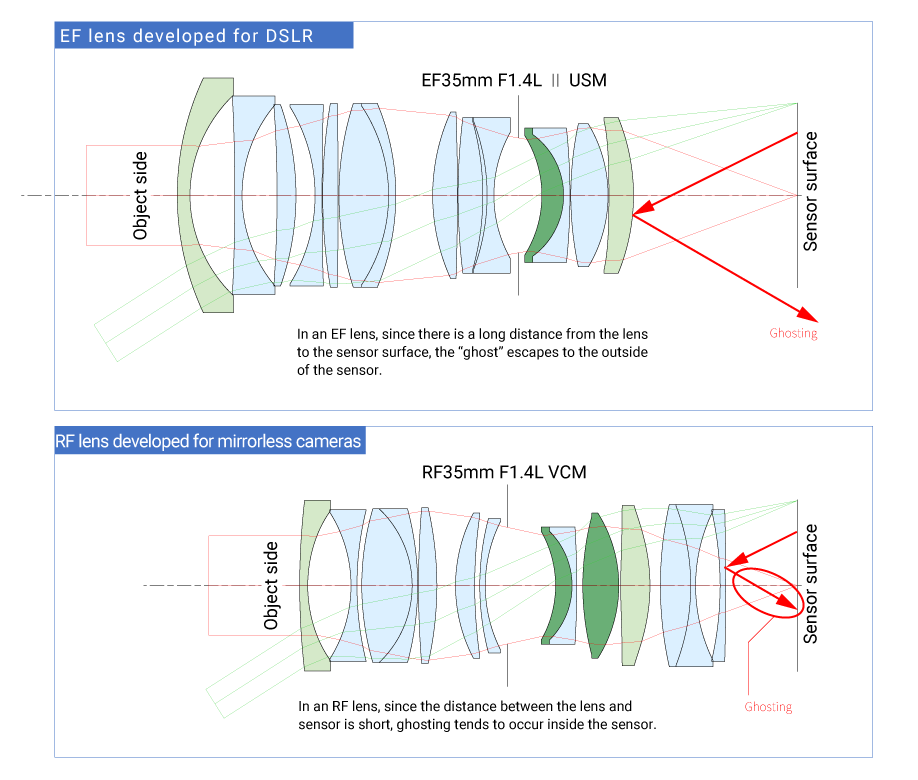

The short back focus used in RF lenses may appear to have no downsides. However, because the image sensor and lens are positioned close together, one unfortunate outcome is the frequent occurrence of “ghosting.” *1

- *1 A phenomenon in which a portion of intense light entering the lens bounces off lens surfaces and projects a circle of light onto a captured image.

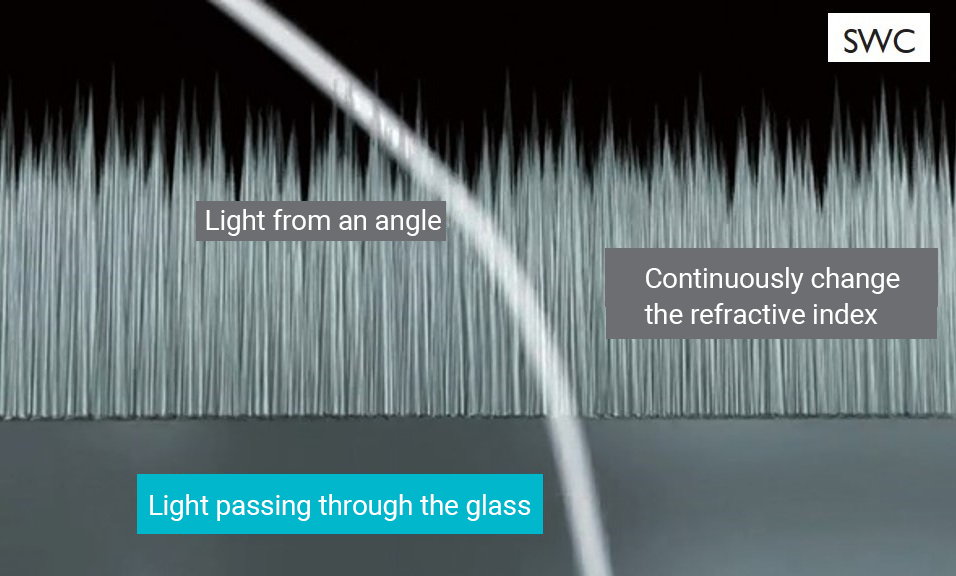

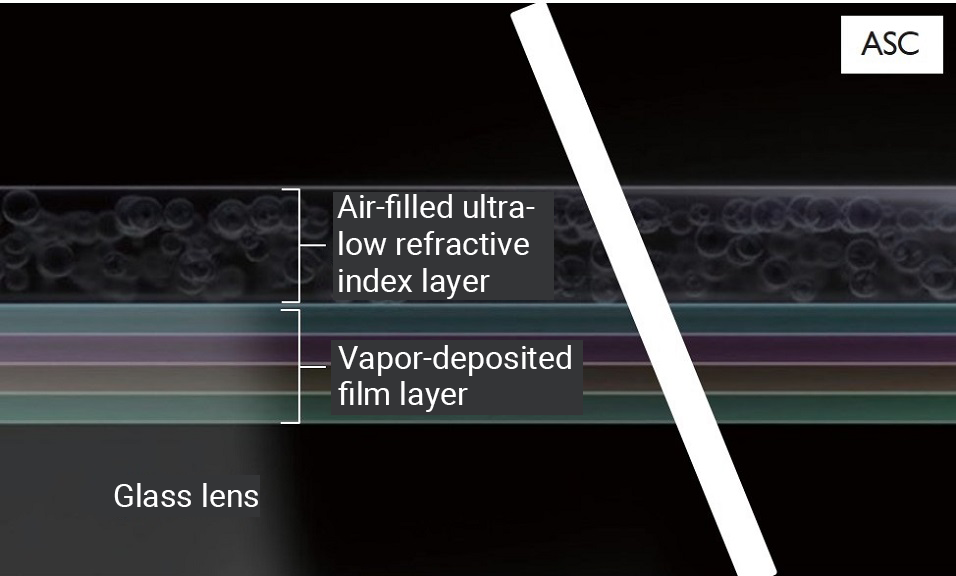

It was Canon's high-quality lens coating technology, which has been nurtured since the days of single-lens reflex cameras, that solved this problem. Canon has developed proprietary technologies called SWC*2 and ASC*3 over many years. We have been able to precisely control the reflection of light through steady efforts, such as establishing a manufacturing method to generate a large number of nano-sized wedges across the lens surface. By applying these two coating technologies adequately to eliminate ghosting, Canon is furthering the evolution of RF lenses into high-quality interchangeable lenses that fully deliver the benefits of short-back-focus construction. Canon continues to pursue smaller, lighter lenses with higher image quality so that photographers can capture images in a more comfortable and engaging way.

- *2. SWC: Subwavelength Structure Coating. An anti-reflection technology that controls light by arranging a large number of wedge-shaped structures smaller than the wavelength of visible light on the surface of a lens.

- *3. ASC: Air Sphere Coating. An anti-reflection technology that suppresses flare and ghosting, especially for light incident at an angle close to vertical, through coating that contains a certain amount of air.

Publication date of this article:May 21, 2025

Click here to access an article on improving the image quality of RF lenses.

List of Content

Maintaining Trust in the Canon Brand

Vol.11

Vol.10

Vol.9

Vol.8

Vol.7

Vol.6

Vol.5

Vol.4

Vol.3

Vol.2

Vol.1

Canon QA Activities

Quality Management at Canon

Safety Program

Security Measures