Maintaining Trust in the Canon BrandVol.2 The reason behind the "white lens": Searching for a brand-new coating

Track & Field, Rugby, Soccer, Motorsports and more—wherever top athletes gather to compete, there are photographers ready to capture their moments of glory. You've likely seen rows of white lenses at many of these events. But why are they painted white? There is, in fact, a very important quality-related reason why Canon’s telephoto lenses, commonly referred to as "white lenses," are coated in that special shade of white paint.

Assistance for the decisive moments

So why does Canon make its telephoto lenses white? The reason is because of "heat." When photographers are outside, under the blazing sun, even a slight warping of the lens components due to heat can have a negative effect on the resulting photo. And holding a hot lens for long periods of time is a burden for photographers.

Even under these harsh conditions, Canon wants photographers to get the best possible shot. This is the motivation behind Canon's decision to use white, the most effective color for reflecting heat, on its lenses.

Various tones of white

Have you ever touched a black surface that has been sitting under the sun, only to reflexively pull your hand away because of the intense heat? That's because the color black absorbs light very efficiently. Energy from the sun becomes heat, raising the temperature of the object. Some colors absorb light particularly efficiently, while others do not. Compared to other colors, white is known to be especially resistant to absorbing light.

However, Canon's lenses aren't "pure white." Although pure white lenses are superb at blocking heat, they also shine particularly brightly, interfering with the shots of other nearby photographers. Out of concern for such effects, Canon chose to adopt a slightly off-white shade—a softer white that didn’t reflect light quite as harshly. This decision is what led to the distinctive shade of white used by Canon's lenses.

Canon white: over half a century of history

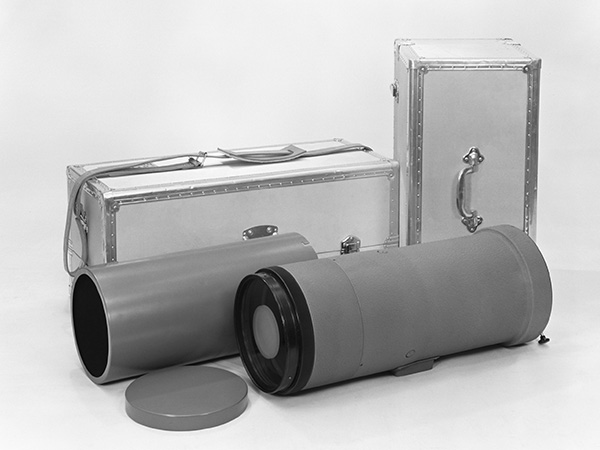

The story of Canon's white lenses begins more than 50 years ago, when Canon adopted the color for its broadcast camera lenses in 1960. In 1976, white was first used for its SLR camera lenses. Looking back at Canon’s catalog of white lenses, you can tell that the shade of white they sport changes gradually over the years.

Just like its cameras and lenses, Canon's "white" has continuously been improved. And in 2018, Canon's white lenses underwent yet another evolution with the release of a new model with a heat shield coating, representing a new step in its commitment to quality.

Creating a whole new kind of "white"

So what kind of "white" is Canon's new white?

Canon's primary objective was to create a "white" with better-than-ever heat shielding. Of course, that wasn’t the only goal—the new white also needed abrasion resistance to avoid scratches while photographers are shooting in various outdoor settings, prevents discoloration even when exposed to sunlight for long period of time, and of course, a white suitable for the Canon brand. Canon set out to find a white coating that managed to meet all of these conditions.

To resolve this dilemma, the production technology team began researching various types of heat-shielding coating. Similar materials used in the construction industry, but these materials didn't have sufficient rigidity to deliver the durability, vibration resistance and shock resistance that photographers needed—just a small bump or shake would result in damage. Unfortunately, these materials could not produce a level of quality the "Canon white" the company was looking for. Instead, they would have to create it themselves. This is when Canon began to develop its own coating materials.

Proprietary development to overcome challenges one by one

If Canon was going to develop its own type of lens coating, how would it manage to realize heat-blocking properties? The approach adopted at the time was to replace the material that absorbs heat with a different kind of material. The material used to adjust the color of the existing white coating absorbed infrared light. By switching to a material that reflected infrared light, engineers were able to contain the rise in temperature of the lens body.

From there, Canon worked on developing and mixing materials that were resistant to ultraviolet light, which caused color fading, and materials that guarded against scratching. Eventually, the company developed a new lens coating that was resistant to heat, scratching, climate and much more.

At the same time, Canon was also making adjustments to coating color. A "Canon-like white" was absolutely essential—a key element of the company's brand identity. Engineers steadily repeated tests and checks with countless samples, making gradual adjustments to shade and even texture to produce a coating that wasn’t too bright under the intense sun and even felt good in users’ hands, in order to produce a coating that was truly worthy of the lenses.

Application of the coating also required delicacy and precision. Depending on how thickly the coating is applied, the level of glossiness may be affected, and the lens may even appear slightly off-color. With their own eyes, the design team inspected the final color and texture of the coating. What they were after simply couldn’t be quantified as cold, hard data. But at last, they succeeded in creating a "white" that was perfectly suited to Canon.

No wind—just blazing heat

The development didn't end there, however. Engineers now needed to compare the old and new lens coatings and test whether the new coating guaranteed better-than-ever heat reflection. They placed temperature sensors on the outside and inside of the lenses and took them out to test them under the intense heat of the sun.

Comparing the differences in heat reflection capability was no easy task. Even with a new and old lens placed right next to each other, a minor difference in the position and angle of the attached camera affected how much and where the sunlight fell on the lens. The presence of wind complicates things as well. In order to ensure accurate testing, some engineers made a near-impossible request for testing under intense heat without any wind or breeze at all.

While performing experiment after experiment under the scorching sun, engineers recreated the tests and performed quality checks with lenses left under artificial sunlight, using the same conditions as the lenses tested under natural sunlight.

And finally, development of the new "white" lens was complete.

In this iconic color lies Canon's heartfelt wish that its customers capture "the very best shot and the very best video."

EF400mm f/2.8L IS III USM, EF600mm f/4L IS III USM (released in 2018)

RF70-200mm F2.8 L IS USM (released in 2019)